So for today's work log I am going to show you what you need (apart from a good steady pair of hands and good eyes) to cut acrylic almost perfectly.

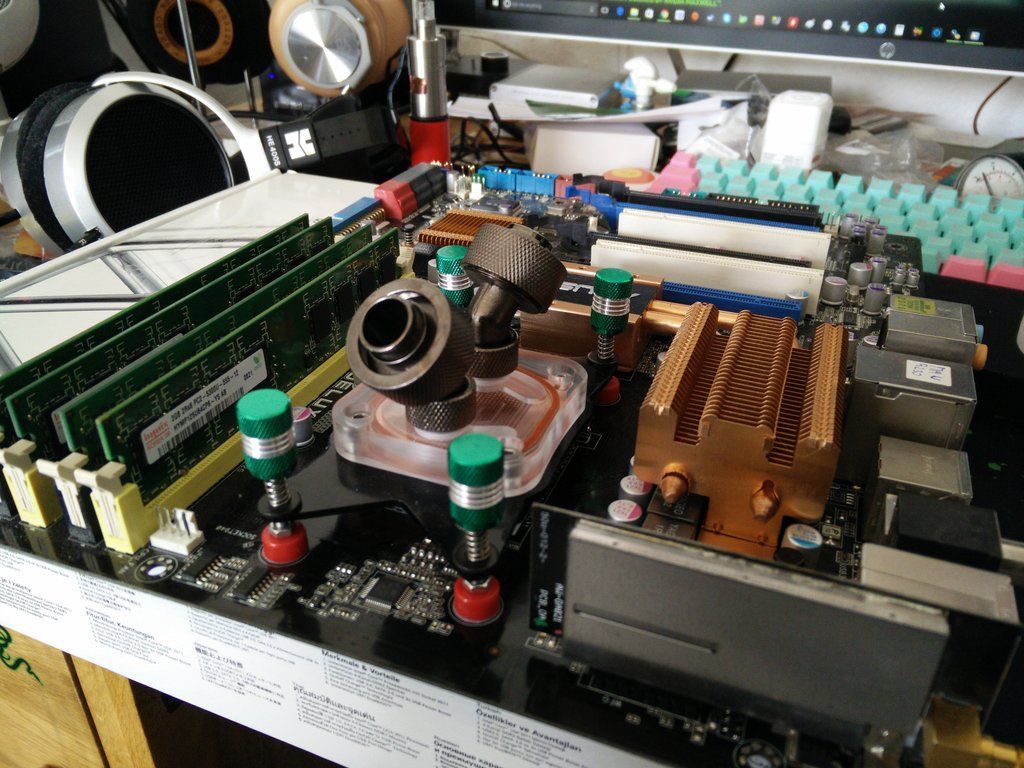

Let's first start with what you need. Firstly you want these.

Obviously you need a rotary tool. You then want one of these.

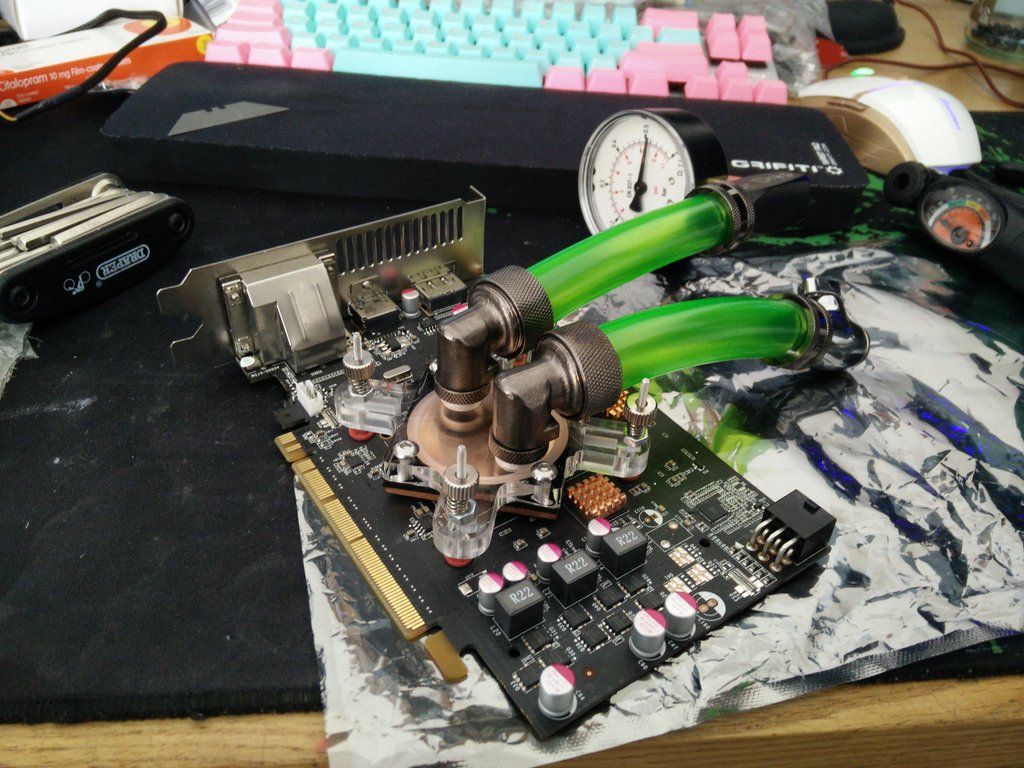

They are called "snakes" and Silverline does a good one pretty cheaply. You then want these. After years of cutting acrylic I have found these to be the best.

25MM Diamond coated blades. Again from Silverline and should cost about a fiver. I am on my second to last one and I bought them four years ago. They last *ages*.

You then want a clean dust pan and brush, one you will only use for this. The reason is you are going to want to sweep the powder and bits off of yourself and using a dirty one sucks.

OK, so those are the basics. As I said with the blades they are the best. No ifs, no buts. Anything else I have used has cabbaged the edges. These things glide through like a hot knife through butter. The snake is needed because a Dremel is like writing with a chisel, the snake turns that chisel into a pen.

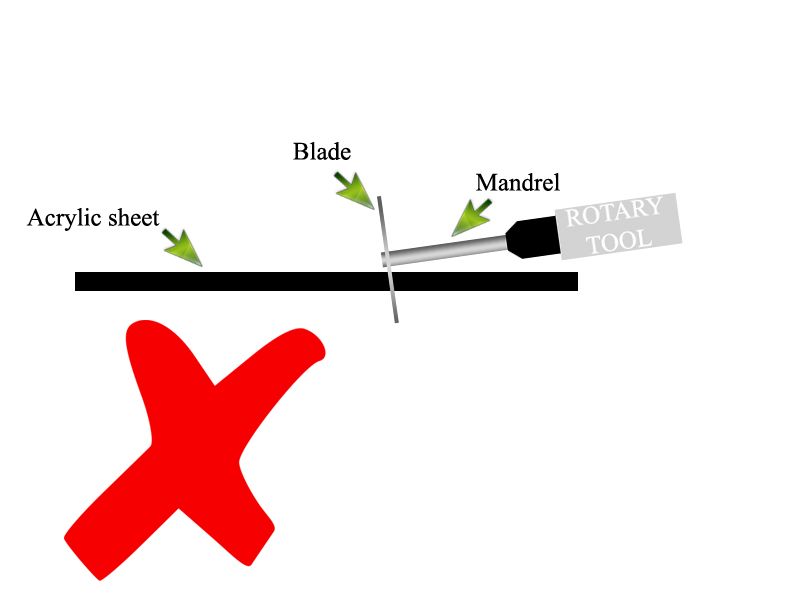

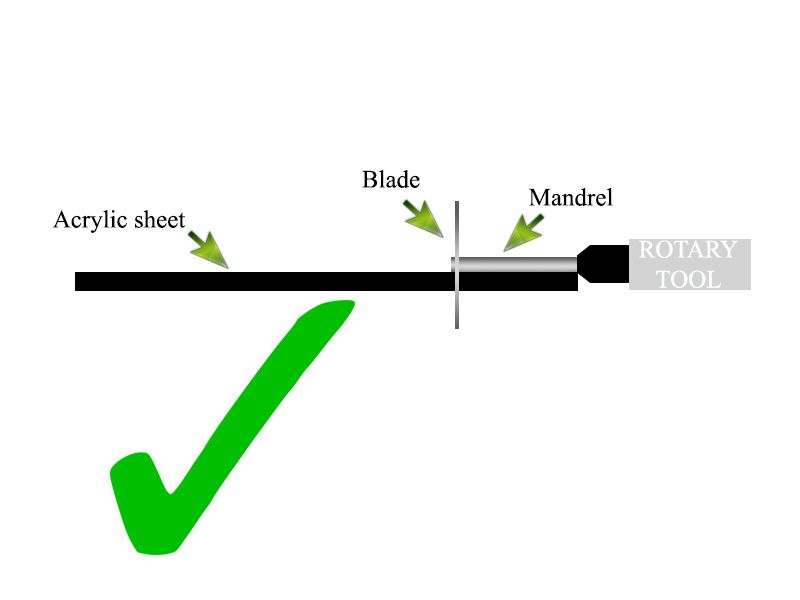

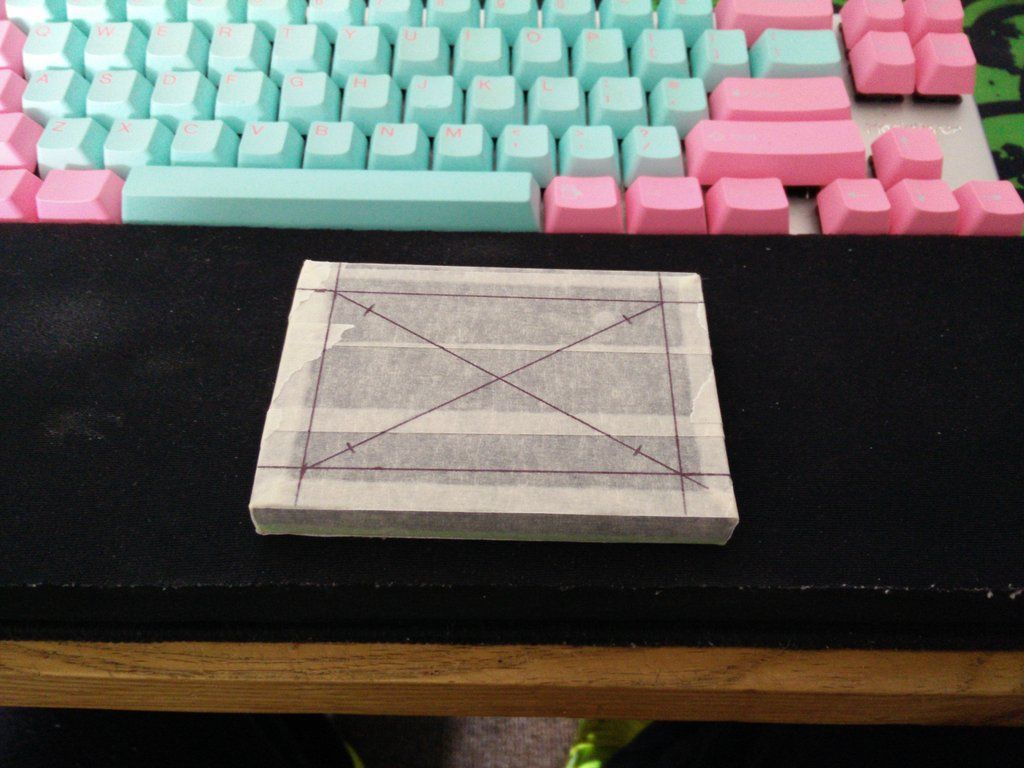

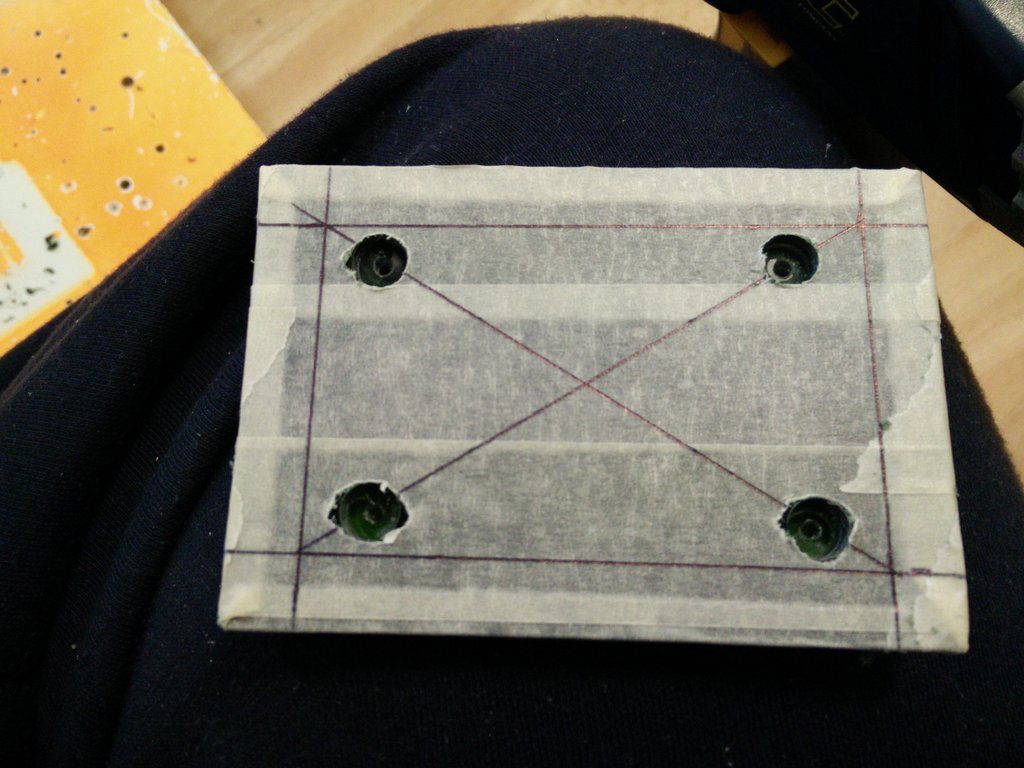

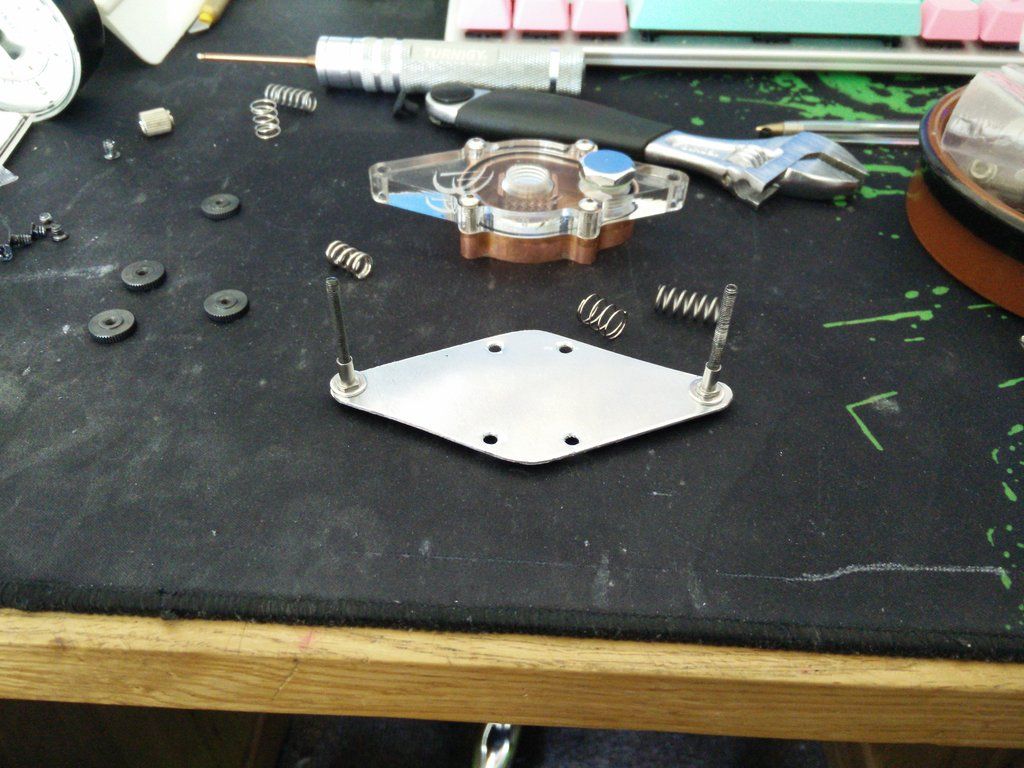

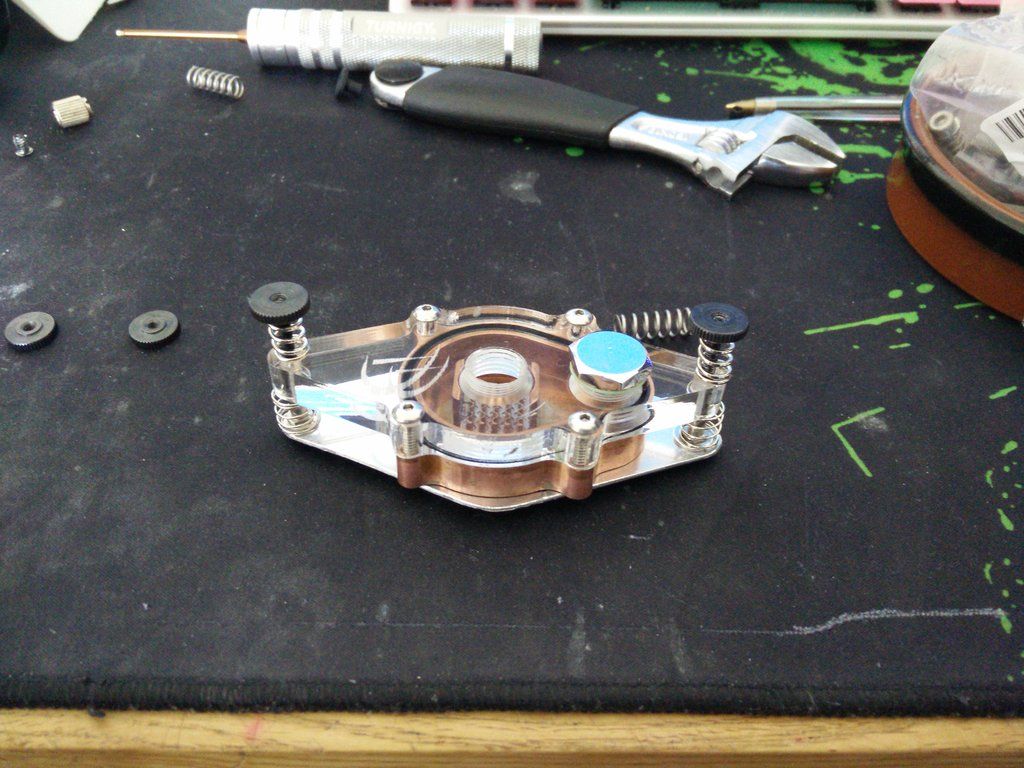

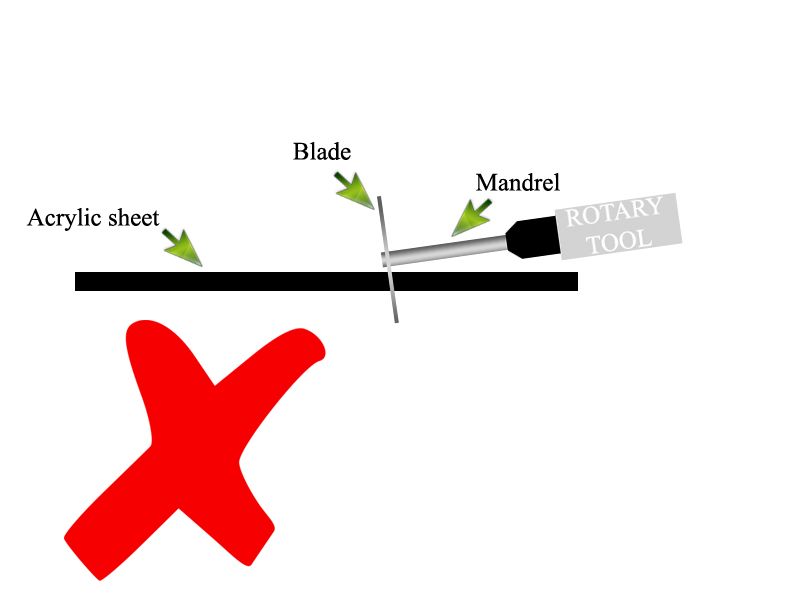

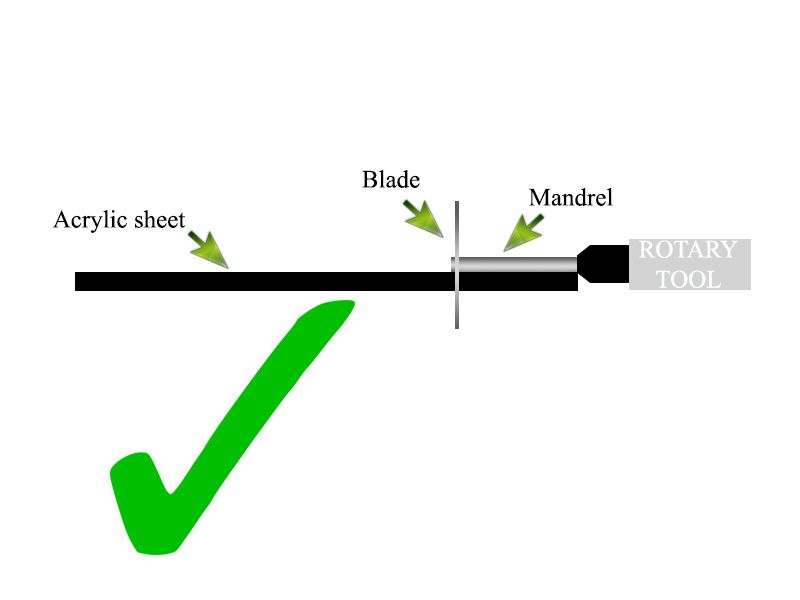

OK, so take a look at these two pics. These are "Acrylic cutting 101" pretty much summed up.

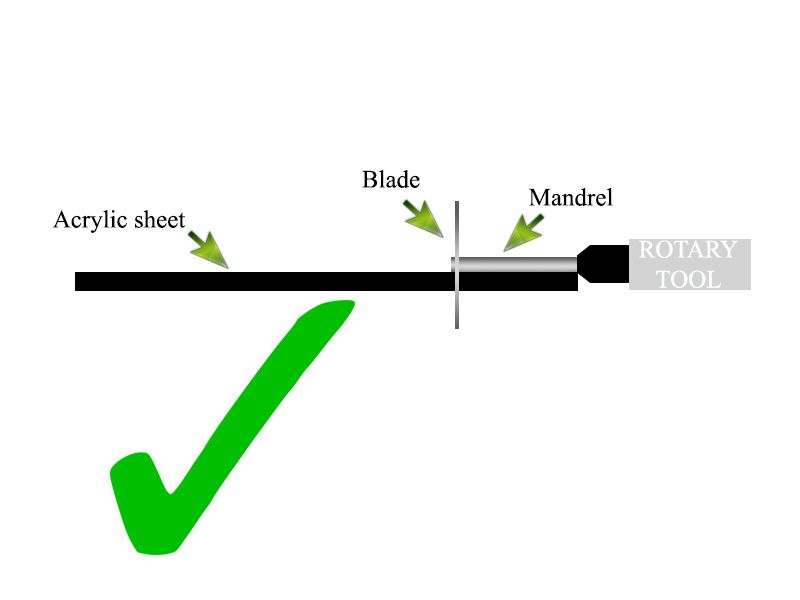

And the correct way.

OK so as you can see if you go in at an angle (which you almost certainly will due to the relatively short mandrel) you will end up with a wavy sloped edge. There is no getting around this unless you rough cut all of your pieces and then cut them again with about 5mm over hang. This way you can put the blade in straight on the edge (as there won't be enough material around your cut edges to foul the tool itself) and cut nice straight lines.

The only down side to this method is that the screw on the end of the mandrel that holds the blade in will scar the edges of your piece. However, this is where I offer two pieces of advice.

1. If the part you are cutting is the same both ways (IE you can flip it over and it will be the same) then it's OK.

2. If the part is not the same flipped over then you need to print your stencil (or mark it out with a ruler and pen) flipped. This way the scar edge will become the back when you turn it over.

I have tried practically everything I can think of to stop this scarring but even two layers of duct tape was not enough. That screw spins fast and gets really hot, melting straight through any tape or protection. I even tried lining up an alu sheet with the piece but the screw jammed and sheered off.

I also do not recommend trying to keep the screw off the edge. If you do then the blade will likely snag and come out as you are cutting.

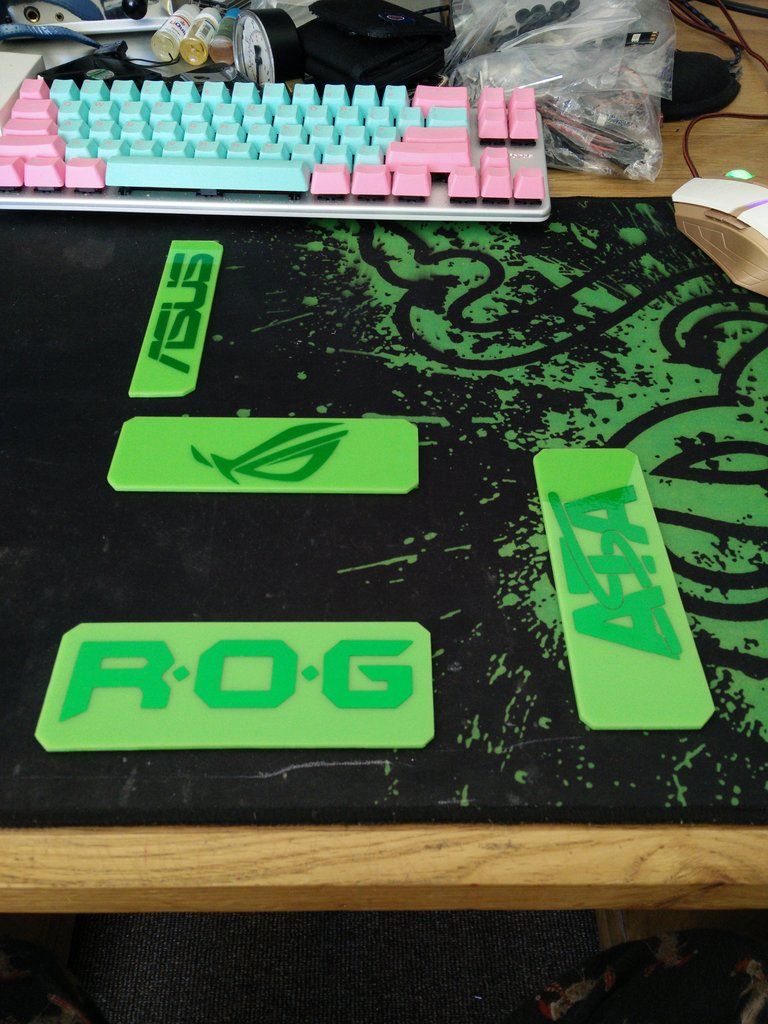

OK, so step one - Design.

Step two - Stick down or mark out with pen and ruler.

Noting that I have left around at least 1CM or 10MM between each piece so I can rough cut and then final cut.

This is the bit you should be using. It is good for 3mm and 5mm acrylic.

And the diamond coating.

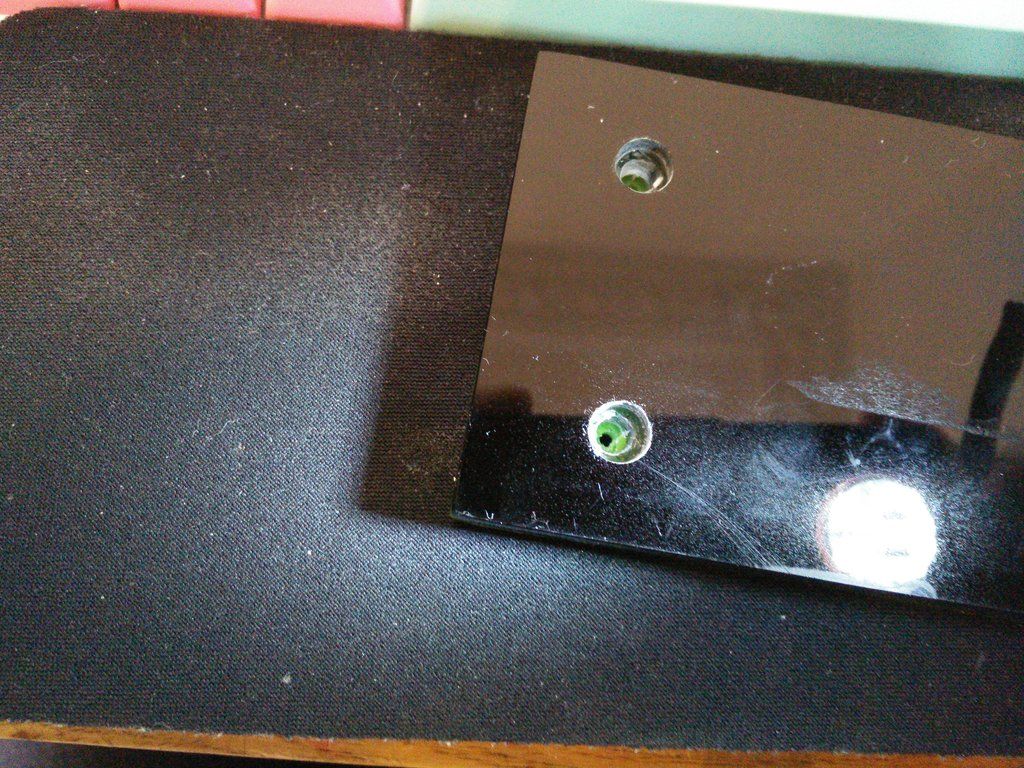

And here you can see me rough cutting each piece the "wrong" way. It's the only way you can cut them now, and you correct it later.

Here they all are rough cut. Put as many pieces as you can along a good edge, that saves you a cut basically.

And now you use this method, as the blade can now go in straight as there is not enough edge material to foul the tool or chuck.

Finish cut.

Then sand. This part is not rocket science, you need a flat surface and a sheet of paper. I am using 600 alu oxide here as it is very strong and lasts. The trick of course is to put the piece down as upright as possible and then just start pushing and pulling back and forth.

*Note. If you are cutting small angled edges like I am then be very careful when sanding them as it's very easy to wee them up and make them look different sizes. Once you mis shape one you will be chasing your tail on all of them trying to make them look the same again.

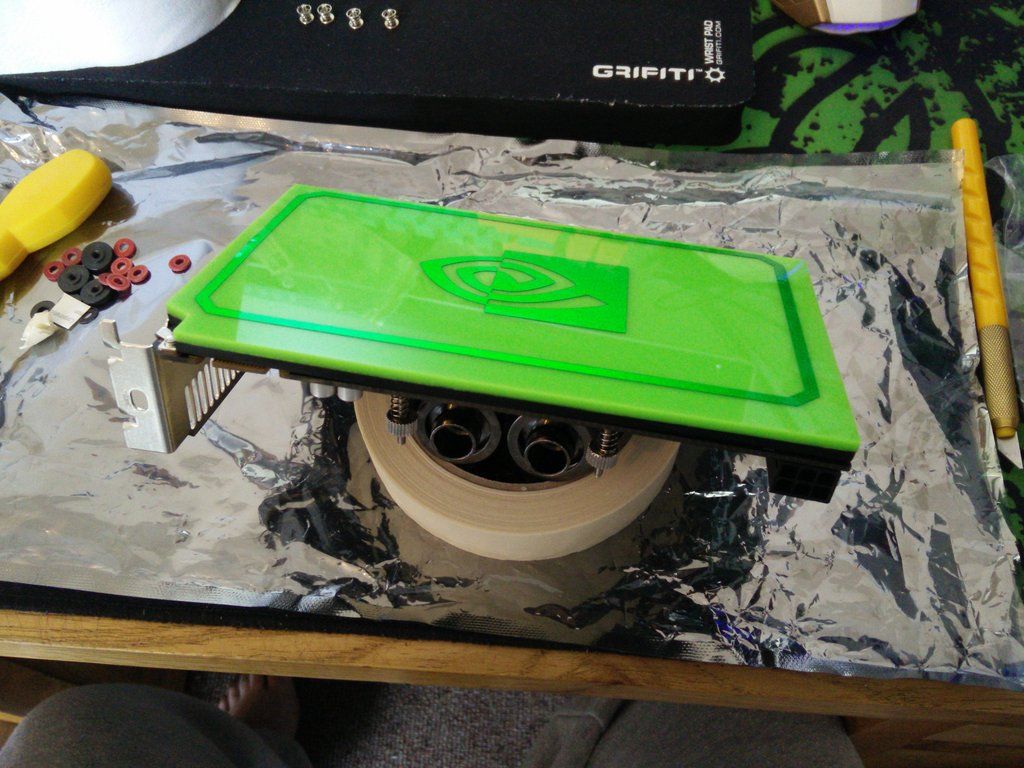

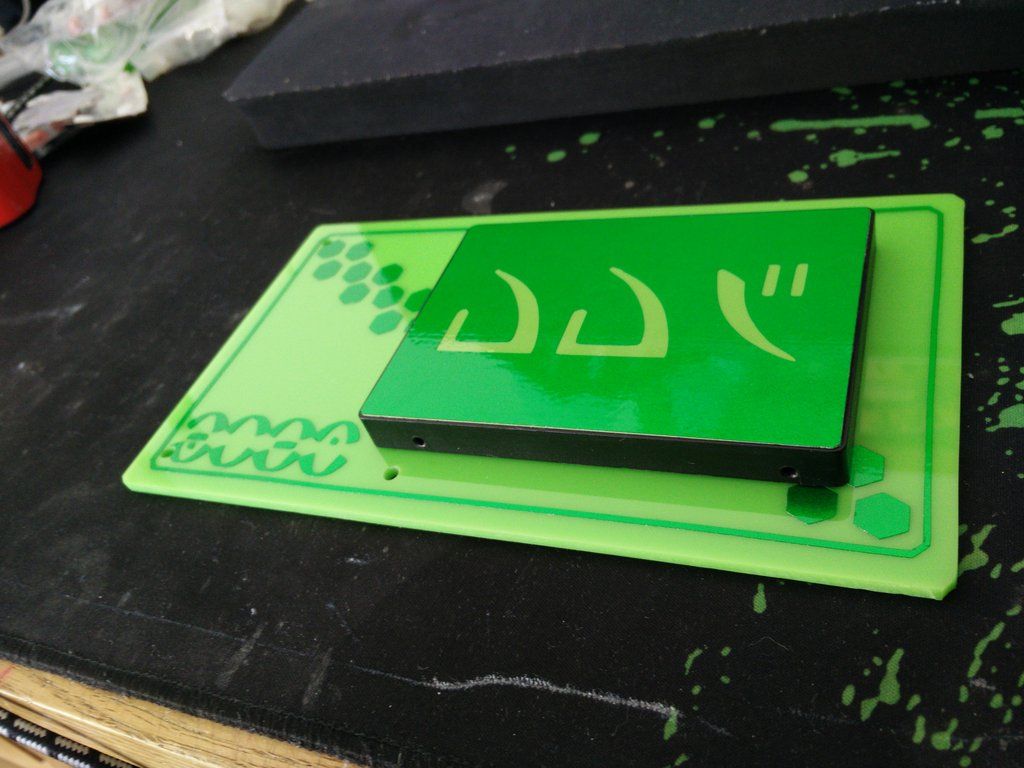

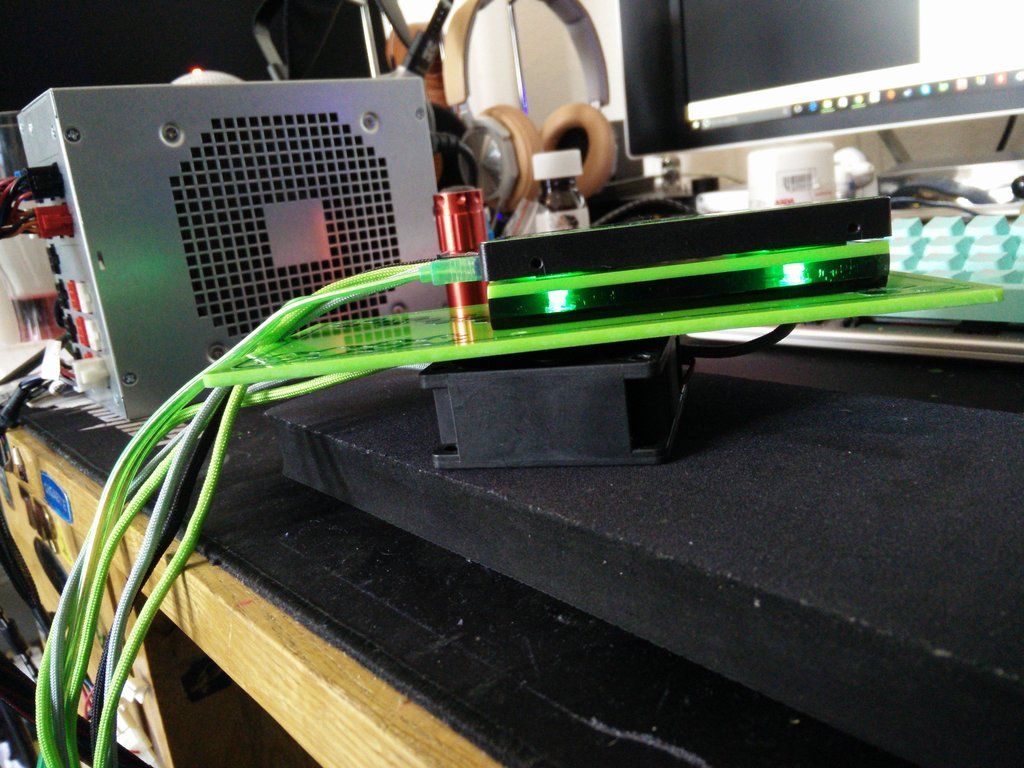

Here are my cut pieces sanded. I will edge polish them later with finer wet sandpaper.

And done. Note, I have left the back side covering on so I know which side to put the decals on. They are also all different sizes, each corresponds to a design so I will know what decals to put where.

Unfortunately I am all out of green metallic and am waiting on an order I placed at the weekend. Should be here tomorrow, then I will do a "how to use a plotter 101"

Be good.