The EVGA SR-2 Black Edition

The EVGA SR-2 Black Edition

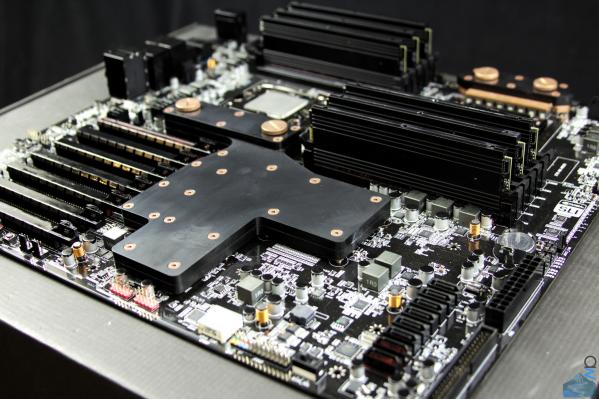

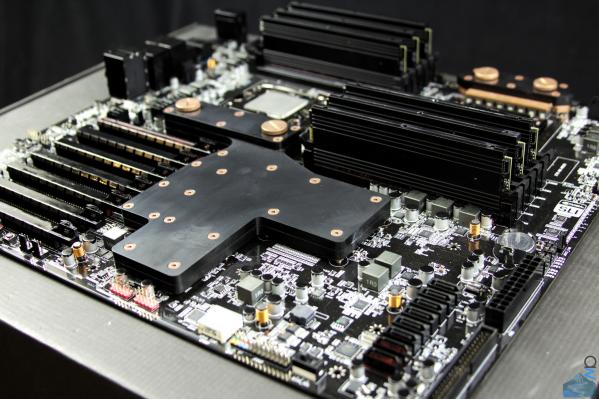

Right then. I think most of us will agree that the SR-2 is a rather smexy piece of hardware. However, two

things:

- 1. The "red" on the PCI and RAM slots is more red-salmon than red. It's not downright ugly, but

it's not a very nice shade of red IMO.

- 2. Even if it were, red does not at all fit into my colour scheme.

So, measures had to be taken. But first, a few images of the stock board, just because I can:

(click image for full res)

(click image for full res)

(click image for full res)

(click image for full res)

(click image for full res)

Also, since we're here anyway: Yeah, I really do have some X5680's in there.

(click image for full res)

(click image for full res)

After consulting with my technical committee...

(click image for full res)

...I first tried out using 3M 1080 car wrap on the PCI-E slots. It didn't actually work too badly, but

it just didn't look right. I'm not sure why TBH, something was just off about it. So, the decision was

taken to paint most of the red bits of the board. In cooperation with some Humbrol Enamel Paint

(and some paint thinner, not pictured, because this stuff is rather gloopy).

Credit goes to Gary Wain (G-Dubs) on the OC3D forum and

his NZXSPC build log for the idea.

(click image for full res)

After the first two coats of paint/thinner mixture it looked like this:

(click image for full res)

Now, no matter how well and thoroughly I paint the board, I was never going to be painting the insides

of the PCI-E and the RAM slots. I have actually heard of a guy doing this with spray paint and then just

yanking a board in and out a few times (therefore scraping off the paint again), but I wasn't willing to

risk my board on that. So, I had to devise a different plan, because the red here was still bothering me

quite a bit.

Therefore: 3M to the rescue!

(click image for full res)

The idea was just to cover the top sides of the PCI-E slots. This also allows me to just take off the wrap

again if I ever need to use more slots.

After wrapping the PCI-E slots, I also painted them with the Humbrol mixture to have the same shade of

black everywhere (this pic is still without the Humbrol layer though).

(click image for full res)

Of course, the IO area also got a good dose of paint. You'll notice the paint hasn't properly covered

everything, even after three coats. I don't have any primer for this paint, and I can't/won't use and spray

primer, so it will have to stay this way. Since it's only on the parts which you won't see once the board

is inside the case (can't get the necessary angle of sight), this doesn't bother me that much and I probably

won't further try to fix it.

(click image for full res)

The same applies to the RAM slots: The bits which are still red either can't be covered or will be hidden due

to angle of sight and/or the RAM water blocks. So don't panic.

(click image for full res)

(click image for full res)

And a few close-up shots of the PCI-E slots:

(click image for full res)

(click image for full res)

(click image for full res)

(click image for full res)

(click image for full res)

And the board in its glorious entirety. The PCI-E slots which isn't covered will of course be used

by the Titan.

(click image for full res)

(click image for full res)

(click image for full res)

Imperfections

Imperfections

You'll notice the odd imperfection here and there (for example, the caps and power/reset are

only painted on their tops). Regarding the caps: I don't want to completely cover them in paint

for thermal reasons, and the reset/power switches will be hidden anyway (behind the top radiator).

Any imperfections which are still visible and actually bothering me once it's all mounted in the

case will be corrected later.

Also, keep in mind that most of the imperfections do not stick out at you IRL at all, but I made

sure to have very good lighting for taking the pictures, otherwise you wouldn't have really be able

to see what's going on with all that black on the board.

Now I just hope the board is still OK. I did test the board on Friday and it ran OK, let's hope that

hasn't changed.

So long,

-aw