So onwards and upwards they say.

CPU prep

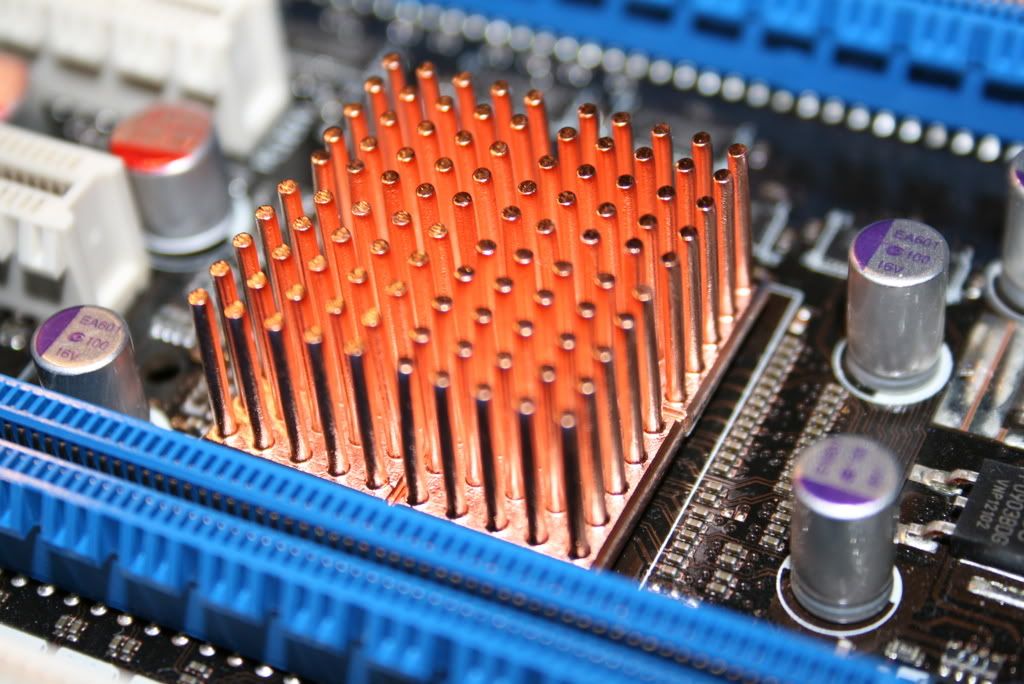

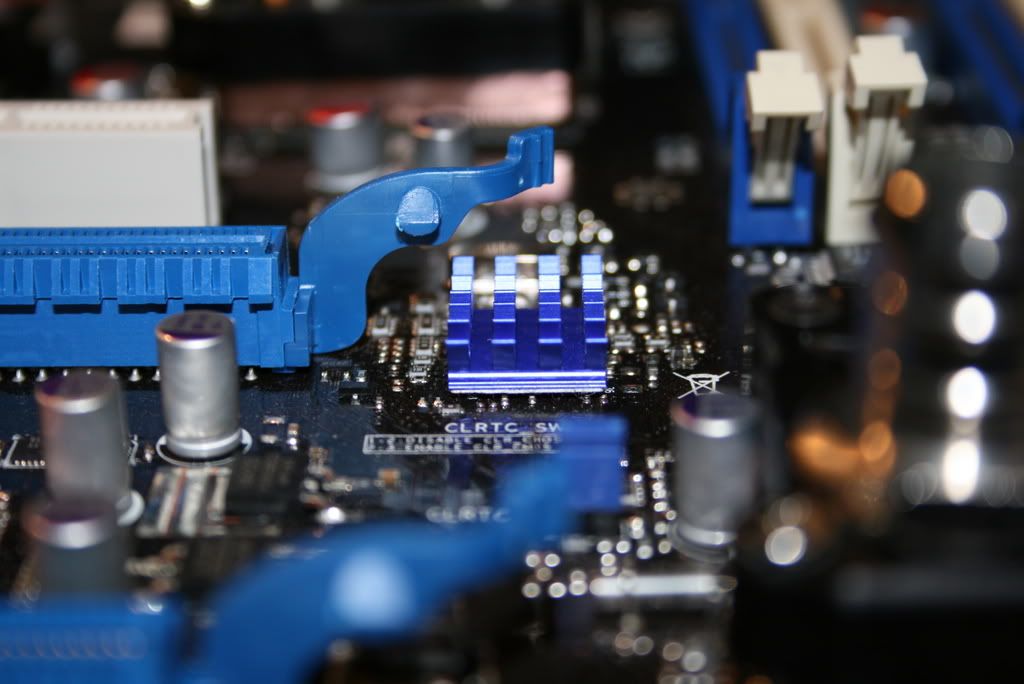

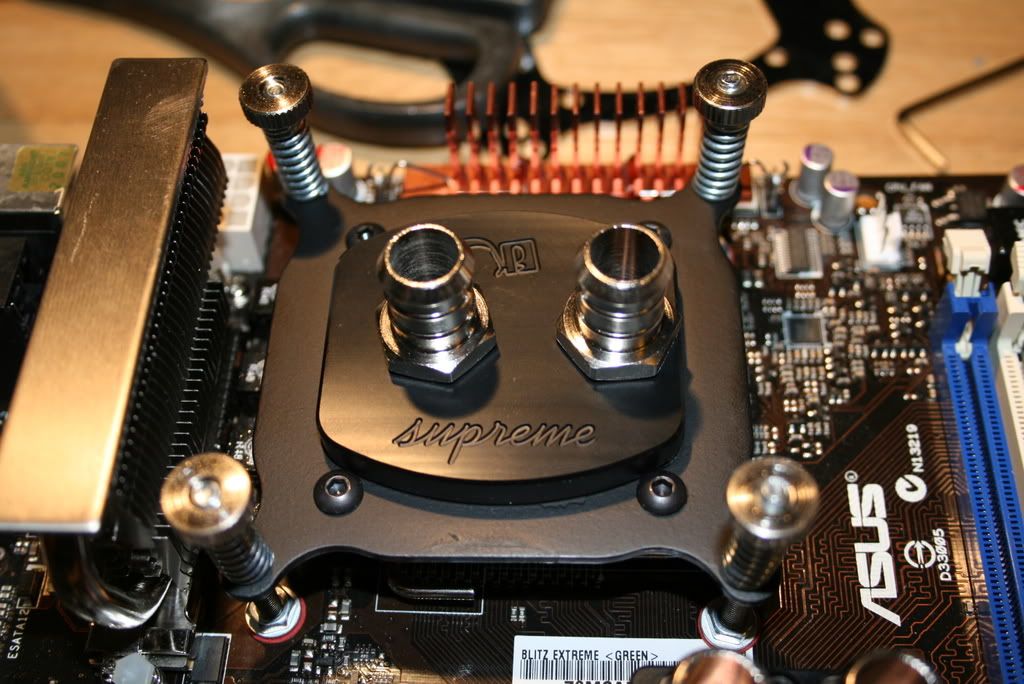

I am going to hold out a little for the QX prices to come down a little (hopefully) and unless I can pick up a bargain in the meantime the cpu I will be using is the Q6600 G0. This little baby is a 45A 'Golden' stepping and has a 1.225vid so it should clock pretty well - as always though its a bit of a lottery.

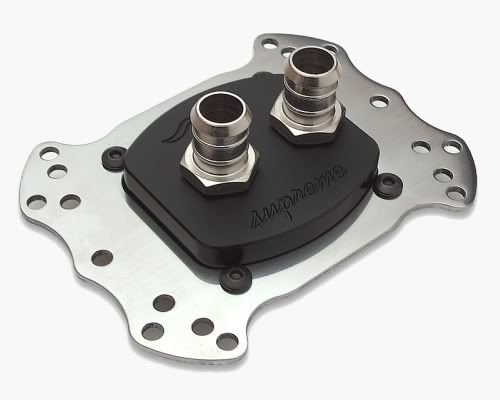

My only hope is that it clocks as well as my previous cpu and can get 4ghz stable with a lower vcore. I heard these chips can run hot so it was time for a little lapping.

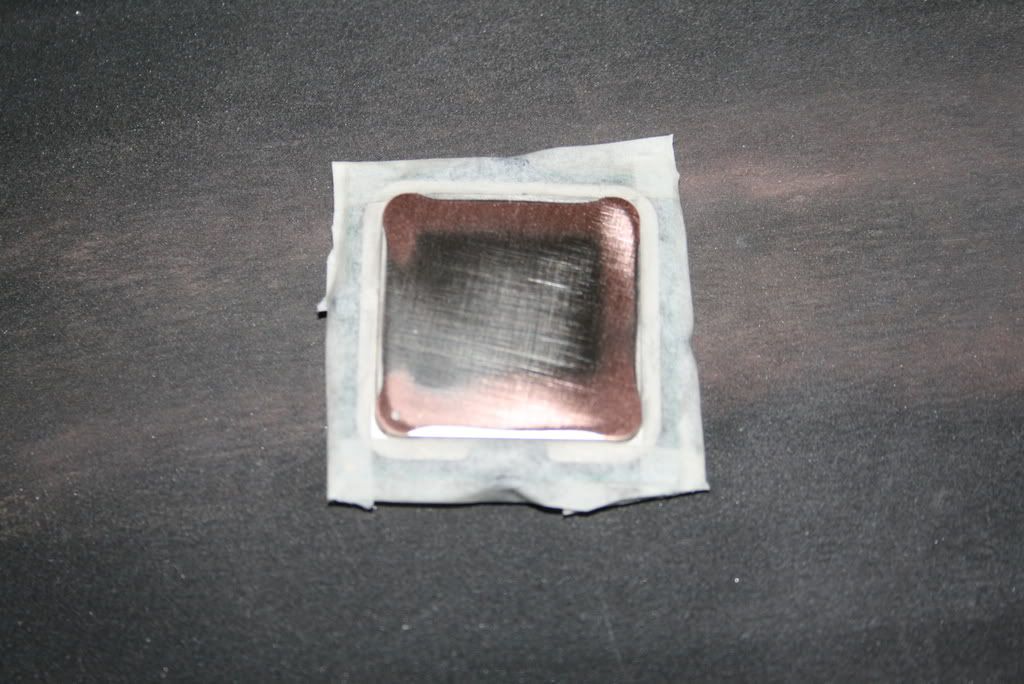

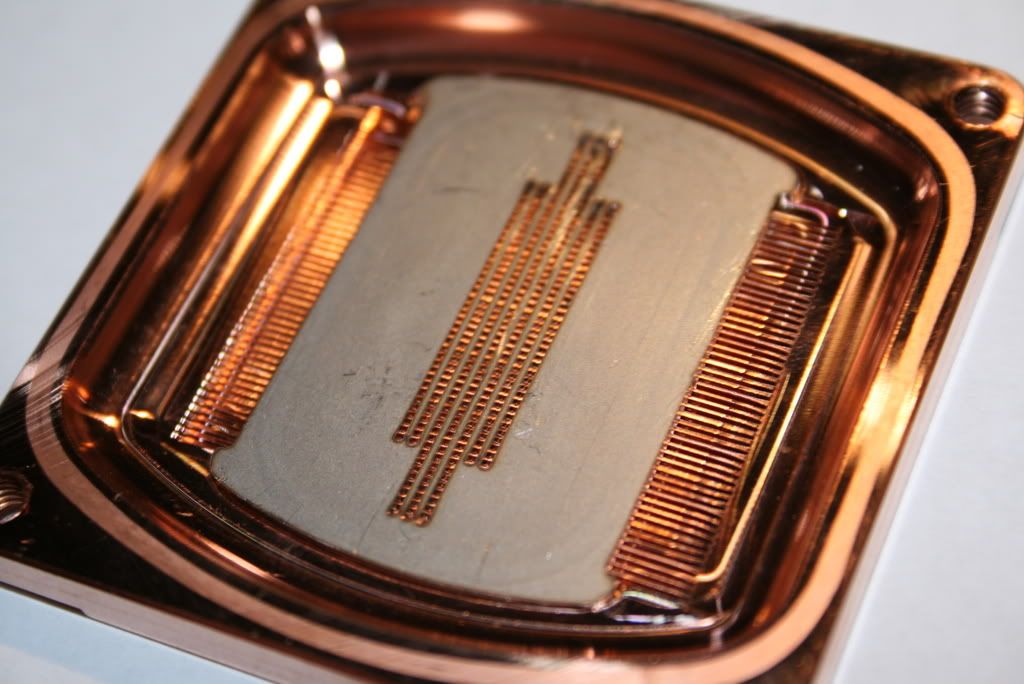

Yup - massively concave as I suspected. Heres how I lap my CPU's. There are a few variances in the various lapping guides out now and I don't really want to go in how it should or shouldn't be done - I have tried most ways and here is what worked best for me :

Tools needed :

400,800,1200,1500,2000 wet'n'dry paper (NOT sandpaper).

Metal Polish

Sheet of glass

Same masking tape.

Prep you surface.

You need a flat surface - glass is perfect for this. I taped the 400 paper onto a sheet of glass. Glass from a photo frame ort mirror is fine if you dont have any other glass to hand.

Prep your IHS

I taped off the 'vent' (dunno what its really called but its the notch bit on the IHS) on the CPU. I also tape the cpu plastic protector plate to the underside of the cpu. Basicly you are preventing any ingress of dust or water to the sensitive bits of the cpu.

Start lapping

Now this is the controversial part. I sand my cpu's down using it dry, alot of people use it wet but I get better results using it dry. The only problem with using it dry is there is a risk of getting copper/nickel dust inside the cpu IHS, but there is a chance of getting water and dust in with it wet but aslong as you tape it off then it'll be fine.

Method

I use the up down for 30 seconds then twist 90 degrees and repeat method, until it gets it flat. It dosn't matter imo whether you use the figure of 8 method or up'n'down - both have the same effect. Just make sure you apply an even amount of pressure to the back of the cpu. You can tell its pretty much flat as all the nickel plating will have gone. It will however look very 'scratchy' so then we go onto the 800 grade paper and so on and so on. After each change of paper make sure you clean the cpu, this stops any further scratching from the lower grade paper when you advance to the higher grade of paper. Each time the scratches will appear less and less until you have a dull shine. Now you can honestly leave it at around 800 grade as it should be flat but it's a little unsightly. You can check if it's flat by using the reflection of the surface with something like venetian blinds or anything that has multiple vertical lines. I use graph paper which works well and shows up any inperfections. Bare in mind the aim of the game is to get the CPU IHS flat, mirror finish is just a by product and not neccesary for low temps.

Mirror finish

I however, like to keep going until I get a mirror finish. This will make no difference to the temps but looks so much better and will get you extra e-peen points.

Once you have got as far as you can with the paper you need to then use a liquid polish/paste which will bring out the shine of the copper. Alot of people will advise against this as in effect you are filling all the microscopic crevices with paste where thermal compound should go which is bad BUT aslong as you buff the paste off and then clean the CPU off with isopropyl alcohol THOROUGHLY, its fine.

Remove the tape and your results should be similar to mine along with your load temps being much lower:

Note: this is my old Q6600. The battery finally died in my camera while taking pics of the new one lol.

.