You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Dianoga (Previously: Project Elvis)

- Thread starter AlienALX

- Start date

AlienALX

Well-known member

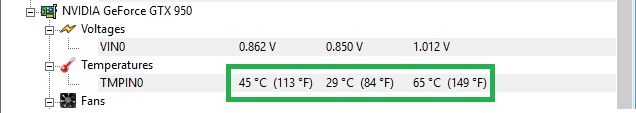

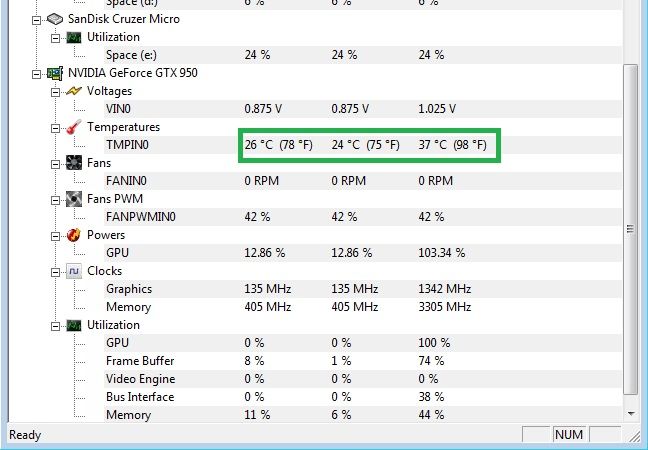

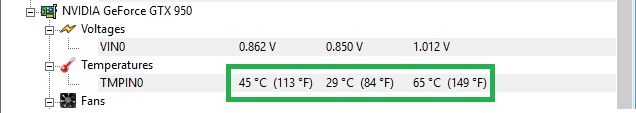

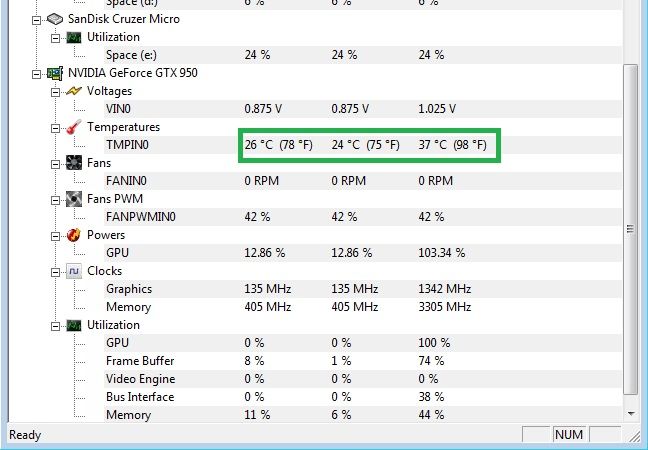

lmao. I was kinda disappointed when I saw the GPU idle temps I must admit. Check out the load temps though !

Before on air.

After on water.

Do note, every fan is on 7v so it's only audible right now because I had to connect a fan to the CPU fan or it errored (I just need to disable it and remove said fan).

Amazing !

Before on air.

After on water.

Do note, every fan is on 7v so it's only audible right now because I had to connect a fan to the CPU fan or it errored (I just need to disable it and remove said fan).

Amazing !

Excalabur50

Well-known member

Dude be careful you'll give yourself a heart attack and if you need cheap Windows key try here https://www.kinguin.net/ it works

AlienALX

Well-known member

All sorted now cheers. I installed Win 7 Ultimate X64 and ran a loader. Once I'm done temp testing I will put Linux on it. I managed to get rid of the fan error. The rig is now almost worryingly quiet. I also fitted the front panel and the top and the hard drive in the top.

I have to make two LED holders, plastic weld the LEDs into them then wire those and fit (the two alien heads on the side panels) as well as fitting an EVGA fan for intake on the side panel.

AFAIK that ought to be it, then I can button it up and take the final photos

Oh, and fit the main cover panel obs, though that literally screws into place.

I have to make two LED holders, plastic weld the LEDs into them then wire those and fit (the two alien heads on the side panels) as well as fitting an EVGA fan for intake on the side panel.

AFAIK that ought to be it, then I can button it up and take the final photos

Oh, and fit the main cover panel obs, though that literally screws into place.

Surfie

New member

A summary of how I am thinking. It begins with C and rhymes with stunt, blunt, and runt.

Ouch looks like you can have a leaky connector.

Time to drain, dry and retest that thing.

Last edited:

Surfie

New member

That doesn't look like leaking to me it's air in the loop turn the case upside down sideways etc to agitate the air bubbles fella

Zoom in on the top connector, there is green fluid leaking out. This could also be allowing air in.

It's a leak.

AlienALX

Well-known member

oh dear not good bud, you not able to just take the block off the cpu and swap the fitting out?

Nope. The block is bolted through from the back and there is no cut out. I did this deliberately though, to give me more room to put cables behind it. (EDIT. Wait yes I could remove the block from the top but those chain gun fittings would also all need to come off. Easier to take the whole thing apart tbh).

Thankfully it is not leaking "static" so I have time to wait for the refund to come back and then order components but it's going to be -

Take the ALX cover panel off (you guys haven't seen this on yet I was saving it *sigh*)

Take off the right panel.

Take off the top.

Take out the GPU (it swings out on rotational fittings)

Put towel over SSD and floor. Lift rig onto table, put bucket under it (small side table)

Take fitting out of ball valve (the 90 deg one)

SPLASH.

Take cap off of res and pump some air through to get it all drained.

Remove bad fitting and replace.

Reverse above steps (putting it back won't take very long)

Pressure test with Dr Drop.

Refill.

At least it's not leaking when static. It only leaks when you move the fitting around.

Also thank god for my GPU back plate and the fact that the SSD is vinyl wrapped, as they resisted the liquid and it all wiped straight off with paper towels.

AlienALX

Well-known member

Well actually that wasn't so bad. I timed myself and it took about five minutes.

I suppose it gave me a chance to test out my drain idea. As you can see I designed it so that the GPU was on rotaries at both ends, meaning it just simply swings out. You then undo the 90' farthest right and when that has drained you open the ball valve, dry off the 90' which is now empty and then blow

I gotta admit I actually quite enjoyed that rofl.

I suppose it gave me a chance to test out my drain idea. As you can see I designed it so that the GPU was on rotaries at both ends, meaning it just simply swings out. You then undo the 90' farthest right and when that has drained you open the ball valve, dry off the 90' which is now empty and then blow

I gotta admit I actually quite enjoyed that rofl.

Surfie

New member

I'd be tempted to test that rotary.

The big problem with rotaries is that there is quite a bit of play in them - which is a mixed curse. It's good because that is what gives you the flexibility, it's also bad, because it makes it easier for water to get past the o ring inside them. And once water is past - that's it.

The fitting itself may not be bad though. IF you had a reasonable amount of pressure on it (say, pushing it in one direction or another), it might be that pressure that is then allowing water through.

You can't test it until it has all dried out though....

The big problem with rotaries is that there is quite a bit of play in them - which is a mixed curse. It's good because that is what gives you the flexibility, it's also bad, because it makes it easier for water to get past the o ring inside them. And once water is past - that's it.

The fitting itself may not be bad though. IF you had a reasonable amount of pressure on it (say, pushing it in one direction or another), it might be that pressure that is then allowing water through.

You can't test it until it has all dried out though....

AlienALX

Well-known member

I've got the fitting off fella  it's gone. With the 90' there are tiny allen bolts on them. With the 45'? nothing sadly. I am going to have to buy a 45' rotary from a known maker (not like this generic crap) and then have a few choices when it comes to a fitting to put into it. I can either use a chrome straight fitting (free) or, something a bit nicer (we will see about that

it's gone. With the 90' there are tiny allen bolts on them. With the 45'? nothing sadly. I am going to have to buy a 45' rotary from a known maker (not like this generic crap) and then have a few choices when it comes to a fitting to put into it. I can either use a chrome straight fitting (free) or, something a bit nicer (we will see about that  )

)

It all depends whether stock is in when I am ready to order tomorrow, 'cause right now I have about £4 in my bank account lol. I knew this was going to be a lean month, as we bought my mother an enormous TV for her 70th. Either way I have a few plans, so something should work OK I thought this fitting was a bit loose when I got it tbh.

I thought this fitting was a bit loose when I got it tbh.

It all depends whether stock is in when I am ready to order tomorrow, 'cause right now I have about £4 in my bank account lol. I knew this was going to be a lean month, as we bought my mother an enormous TV for her 70th. Either way I have a few plans, so something should work OK

Surfie

New member

I've got the fitting off fellait's gone. With the 90' there are tiny allen bolts on them. With the 45'? nothing sadly. I am going to have to buy a 45' rotary from a known maker (not like this generic crap) and then have a few choices when it comes to a fitting to put into it. I can either use a chrome straight fitting (free) or, something a bit nicer (we will see about that

)

It all depends whether stock is in when I am ready to order tomorrow, 'cause right now I have about £4 in my bank account lol. I knew this was going to be a lean month, as we bought my mother an enormous TV for her 70th. Either way I have a few plans, so something should work OKI thought this fitting was a bit loose when I got it tbh.

Ok, you got it out. You could still test it. Pop a cap on one end, and Dr Drop on the other, and hey presto - you have a test situation.

If there is actually nothing wrong with the rotary, then you could still use it fella - that would save you having to buy another one. Still can't test it until it has completely dried out though.

Oh - and I love your idea for the drainage.... good plan!

AlienALX

Well-known member

Ok, you got it out. You could still test it. Pop a cap on one end, and Dr Drop on the other, and hey presto - you have a test situation.

If there is actually nothing wrong with the rotary, then you could still use it fella - that would save you having to buy another one. Still can't test it until it has completely dried out though.

Oh - and I love your idea for the drainage.... good plan!

The drainage was sheer luck tbh. I wasn't going to use a 90 deg rotary fitting in there. It was only when I fitted one and realised it literally pointed right at the GPU that the idea came about

Sadly the 45' fitting is toast dude. When it was fitted it held pressure very well, with no leaks at all. It's very loose though, and if you rocked it on the loose joint it would pee straight out. There's no way I can see to get it apart so it's going. Those smoked "unbranded" fittings are horrible any way, requiring ridiculous amounts of force to seal them.

Ever onward and upward...

Yay

I was poking around on OCUK earlier looking for rotary fittings and I found these on clearance.

In a four pack for £7.99

So now I can replace both of the odd coloured ones with green ones and make up two new 45 deg rotary fittings with these, which I have ordered two of.

So hopefully early next week (well, or the weekend, free second class) I can get it put back together again

Huge thanks to OCUK (they're in my thanks list any way) but I've bought quite a few fittings cheap now from them. Been a life saver three times !

Surfie

New member

The drainage was sheer luck tbh. I wasn't going to use a 90 deg rotary fitting in there. It was only when I fitted one and realised it literally pointed right at the GPU that the idea came about

Sadly the 45' fitting is toast dude. When it was fitted it held pressure very well, with no leaks at all. It's very loose though, and if you rocked it on the loose joint it would pee straight out. There's no way I can see to get it apart so it's going. Those smoked "unbranded" fittings are horrible any way, requiring ridiculous amounts of force to seal them.

Ever onward and upward...

Yay

I was poking around on OCUK earlier looking for rotary fittings and I found these on clearance.

<snipped image>

In a four pack for £7.99

<snipped image>

So now I can replace both of the odd coloured ones with green ones and make up two new 45 deg rotary fittings with these, which I have ordered two of.

<snipped image>

So hopefully early next week (well, or the weekend, free second class) I can get it put back together again

Huge thanks to OCUK (they're in my thanks list any way) but I've bought quite a few fittings cheap now from them. Been a life saver three times !

Ok, either it's really late, i'm really tired, or I have a filthy mind, because I read that OCUK COMPLETELY differently the first couple of times.... Maybe all of these at once. I don't know....

Anyway, sorry to hear that the fitting is toast. At least you have found some good replacements!