AlienALX

Well-known member

The last time I ran Linux it was on a Powerbook G4 17". The aluminium one. I installed Ubuntu because I fell for the hype and thought it would speed the laptop up a bit. It was slower than Leopard, so much for that then. I am either going to use Elementary or something similar to OSX. For the most part when I am not modding I just sit and go around in a circle on the net all day listening to music. That's why I would rather do it on something quieter (my gaming rig is pretty noisy being up here in my face) and plus hardware seems to have a shelf life these days so I would rather put the hours onto a machine that would be cheaper to repair.

A mate of mine used to use Mint but I can't say I was overly enamored with it. Again it just seemed slower than Windows.

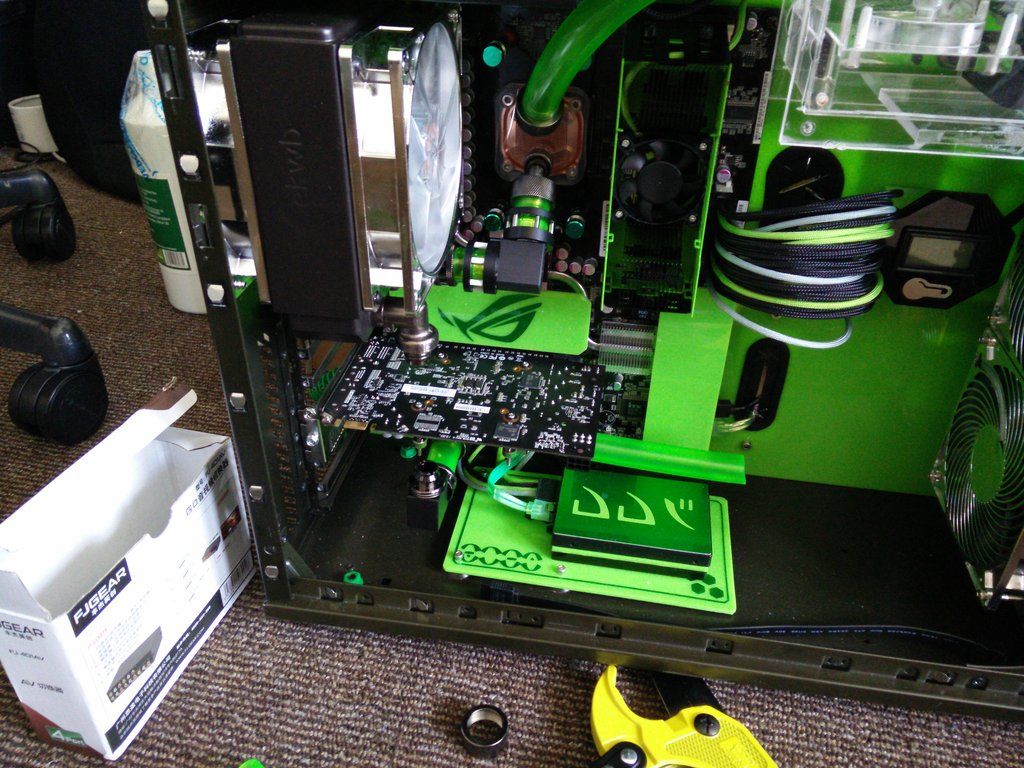

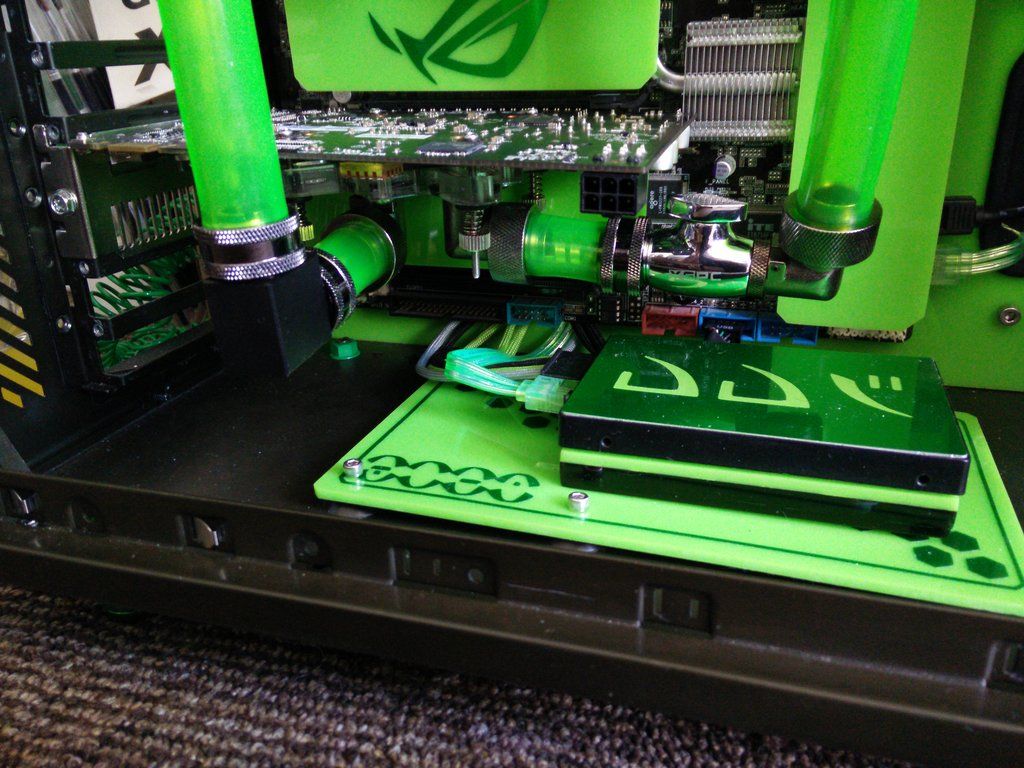

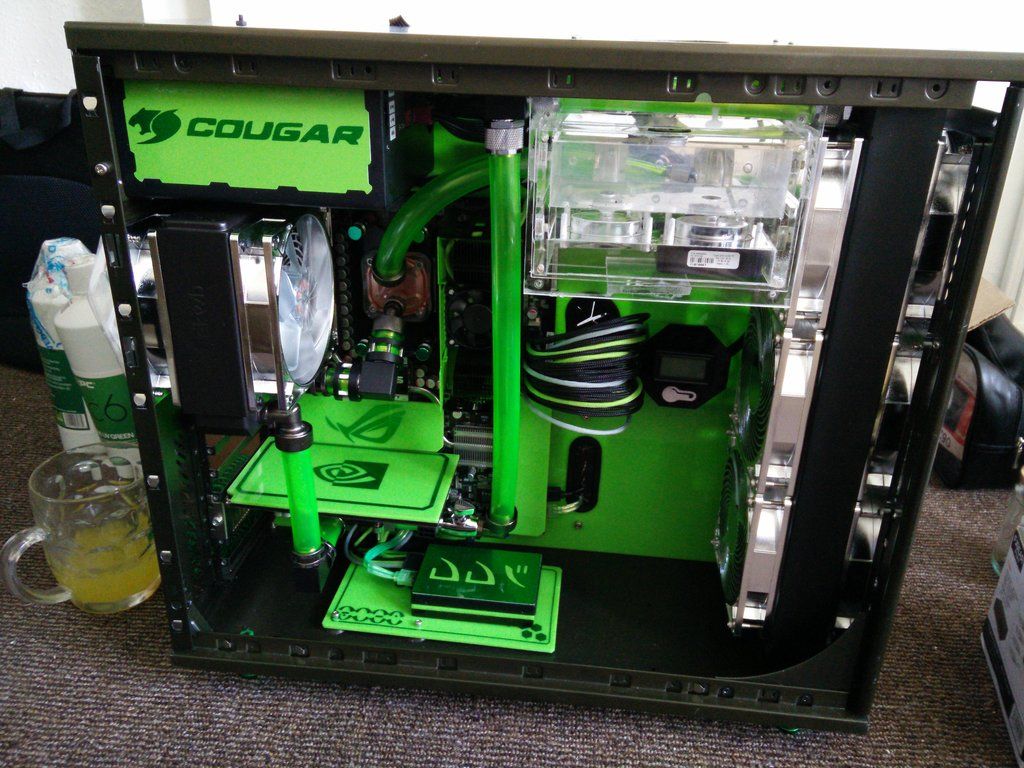

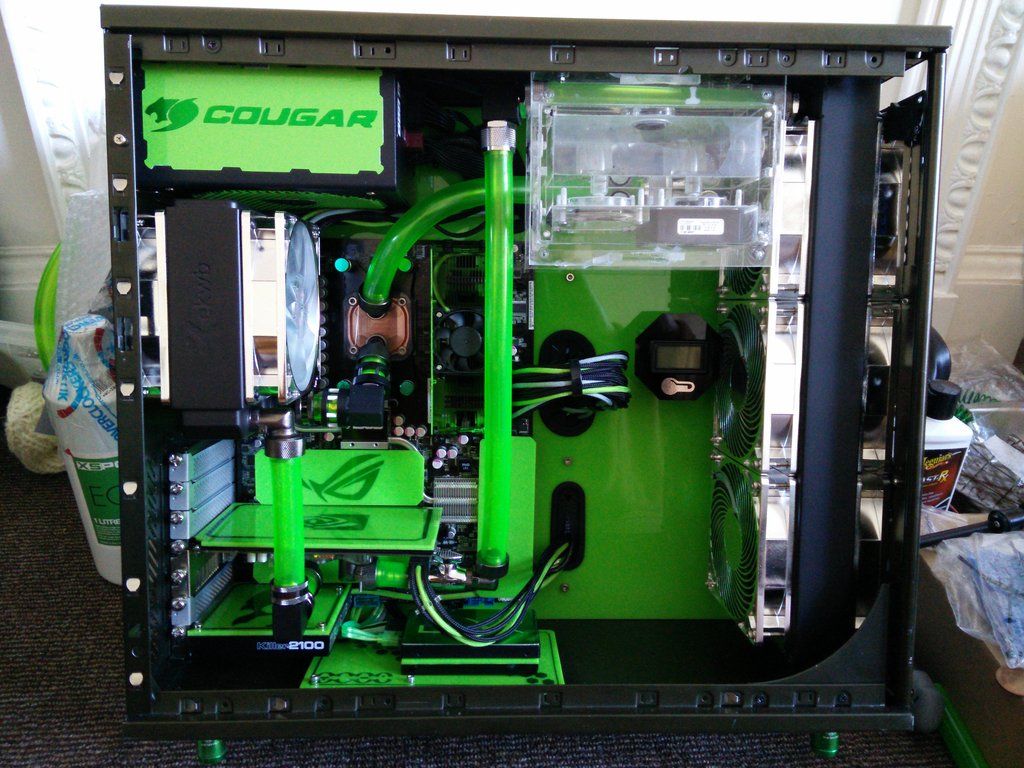

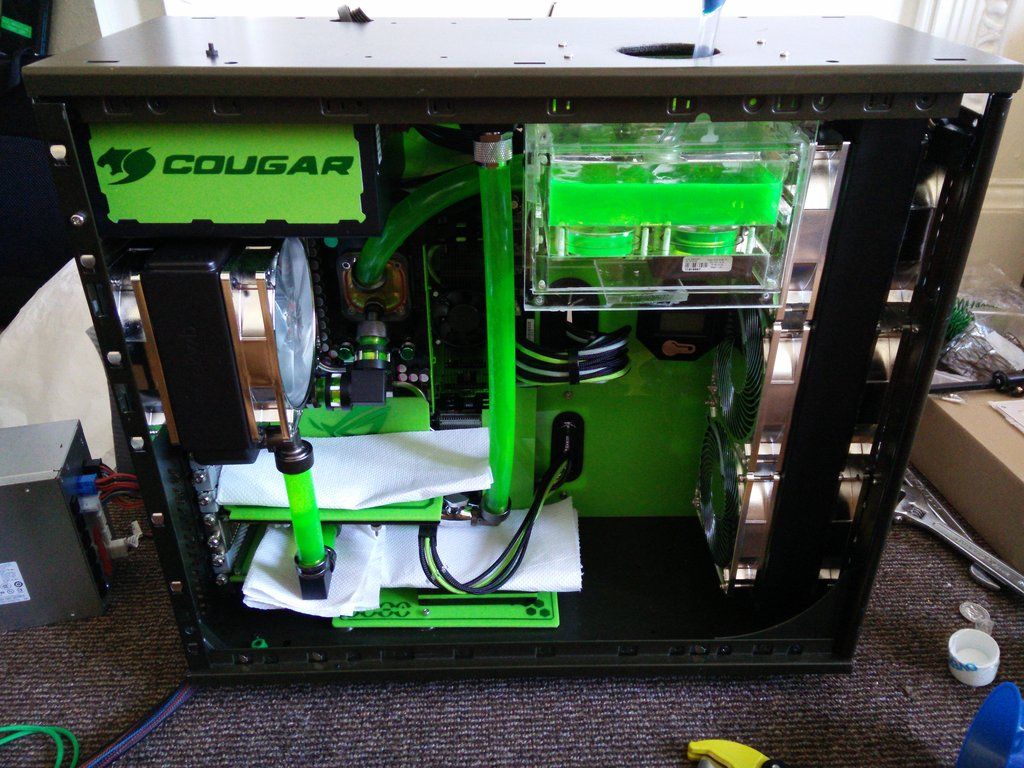

The fill port is the hole in the roof yes mate. I will need to be precise though, as there will be a couple of laptop drives living up there haha. It will be like a roof extension

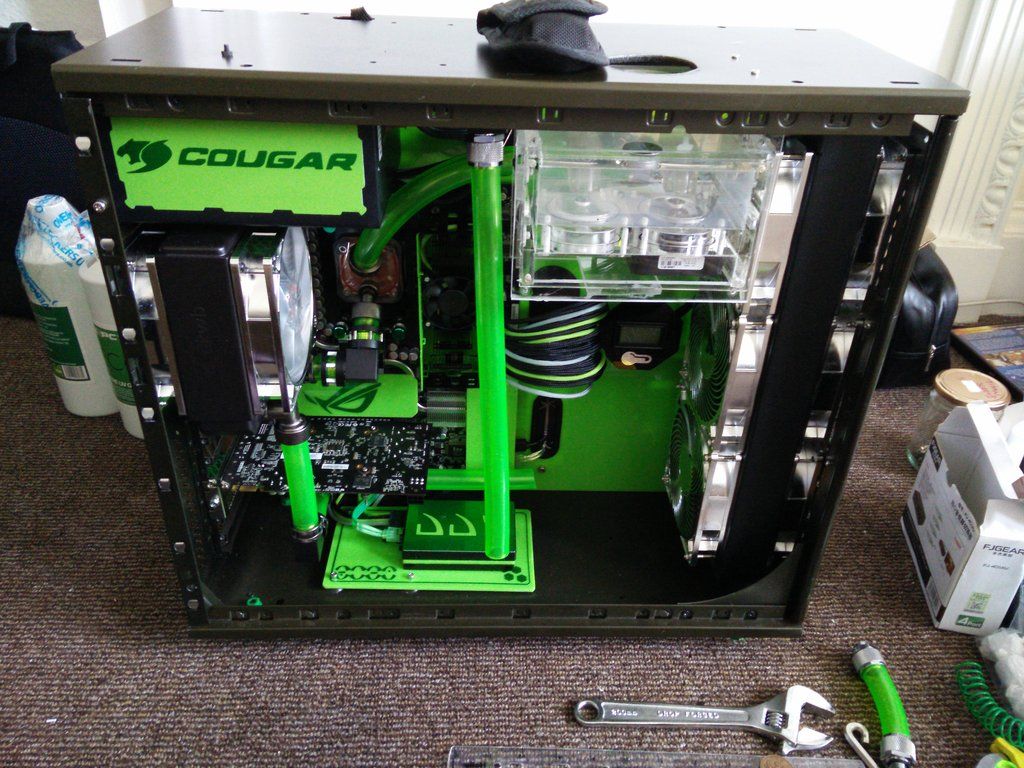

I will undo the plug in the res and then stick a piece of blu tack to it to get it up. Then fill, reverse the process and done. Try and remember, this is a case from 2006. That's a decade in computers, a lifetime in human years. I mean jesus, six months these days and your PC is crap.

But that's me all over. My mate says it best "Why do you have to force things to do what they shouldn't do instead of buying something fit for the purpose?"

Because it's fun

A mate of mine used to use Mint but I can't say I was overly enamored with it. Again it just seemed slower than Windows.

The fill port is the hole in the roof yes mate. I will need to be precise though, as there will be a couple of laptop drives living up there haha. It will be like a roof extension

I will undo the plug in the res and then stick a piece of blu tack to it to get it up. Then fill, reverse the process and done. Try and remember, this is a case from 2006. That's a decade in computers, a lifetime in human years. I mean jesus, six months these days and your PC is crap.

But that's me all over. My mate says it best "Why do you have to force things to do what they shouldn't do instead of buying something fit for the purpose?"

Because it's fun