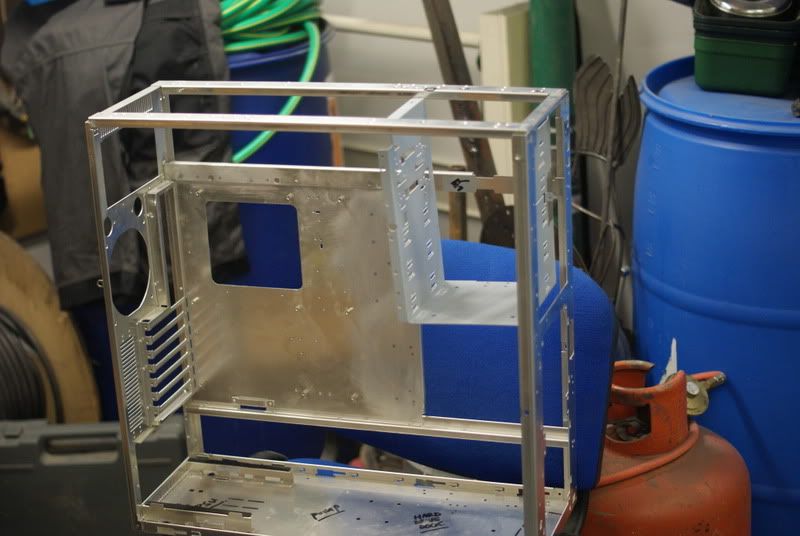

Righto another little update, just been fiddling around removing more bits and sorting out the 5 1/4" drive bays and covering up some mobo stand-off holes.

First, I set about removing the case feet, simple task, just remove the 4 screws and off come the feet.

I really like the Lian-Li case feet, they are rubberised at the base to stop any vibration/ sound leaking, BUT unfortunately, one of them has a dent in. I'm unsure whether to knock it out and risk damaging the ally, leave it as it wont really be seen, or get some aftermarket feet; perhaps the black anodized MNPC ones.

I don't know if you can see it, but its not perfect, so I won't be using, I don't think.

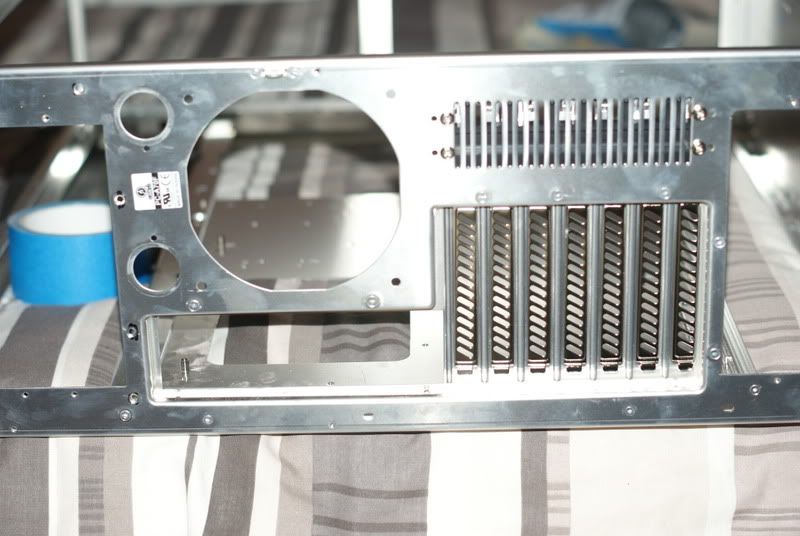

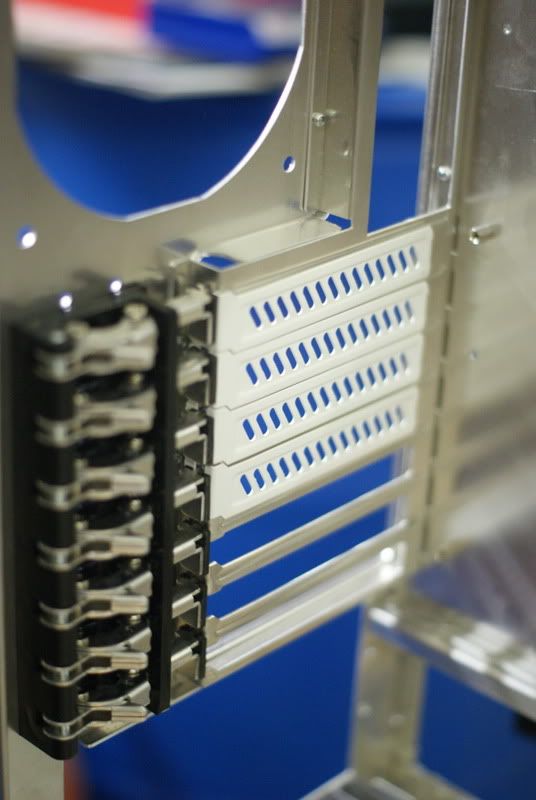

Next up, simple task of removing the expansion slot hot-swap system type deal-i-o.

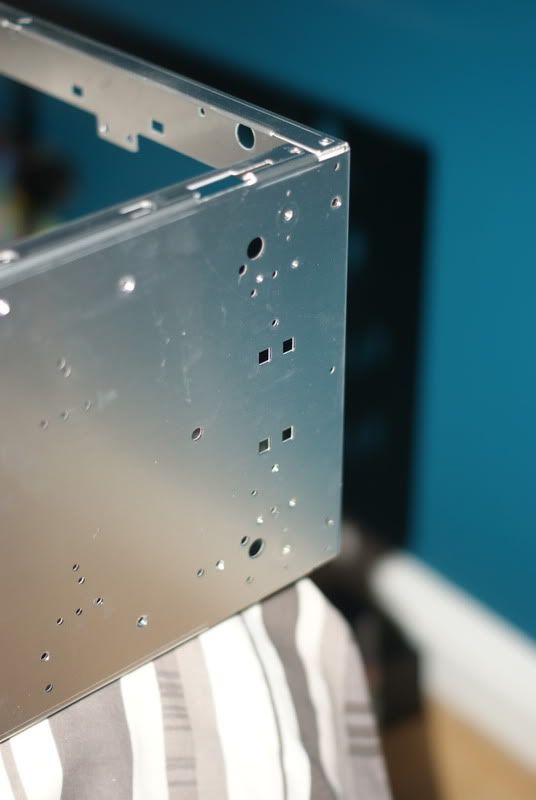

Next, as I am most probably only going to be using standard sized ATX mobo's , the plethora of extra mobo stand off holes are simply not needed, so, I'm going to fill them in.

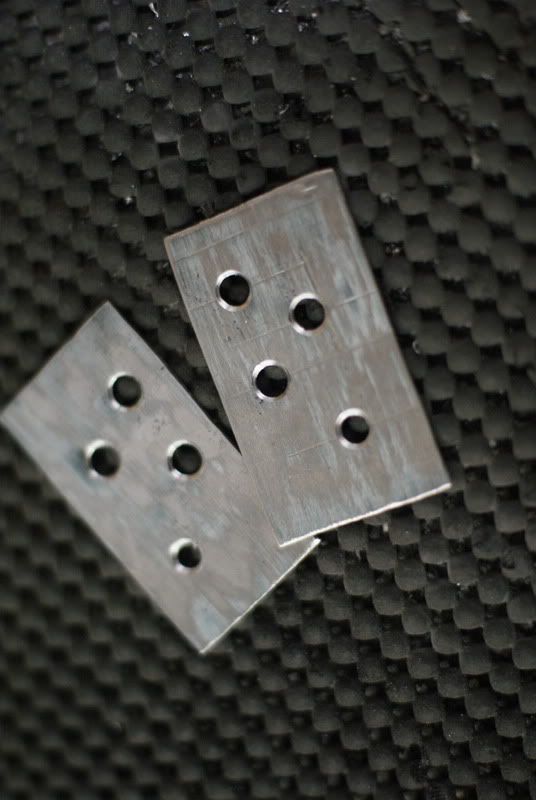

Padding metal to fill the holes in.

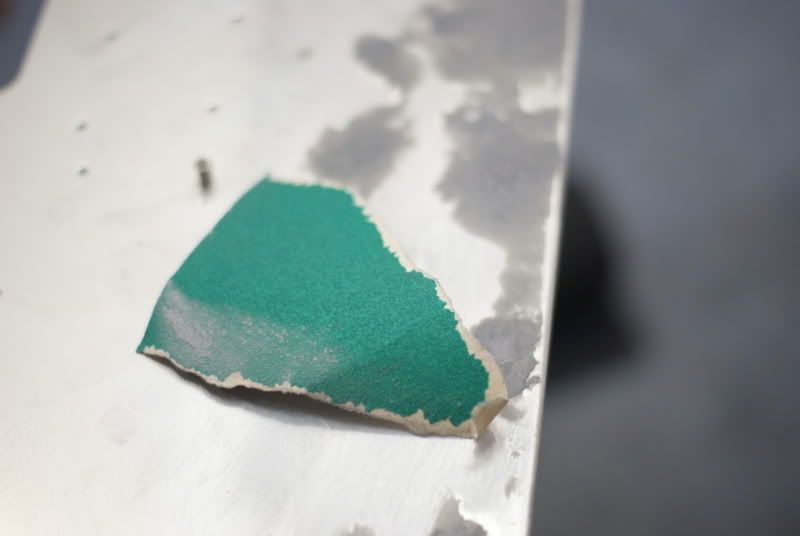

Mix the 2-parts up, equal lengths, not quantities.

Wasn't bothered about how much i put on, I wanted to ensure the holes were filled with enough to be able to be sanded down flush with the mobo tray.

To get the bulk off, I used Liberty Green 160 grit, then 400 grit and finished with 1200 grit.

Cleaning off the run off at the rear of the mobo tray.

All flush and smooth at the front, ready for painting.

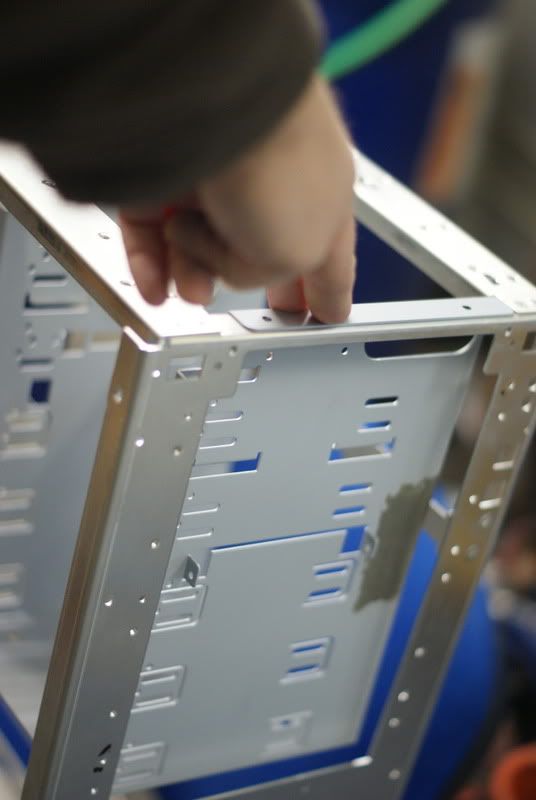

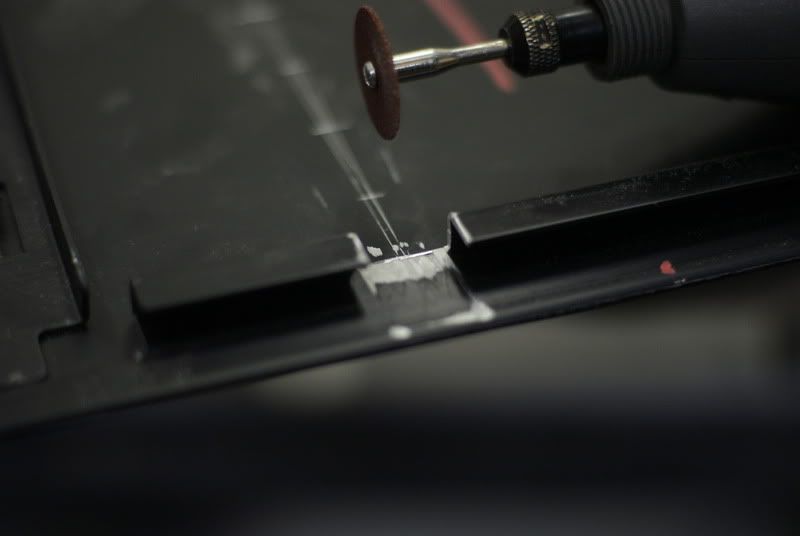

Also had a few chunks that were needing to be filled in at the top off the case, where I had to get the rotary tool out to cut off the top bay.

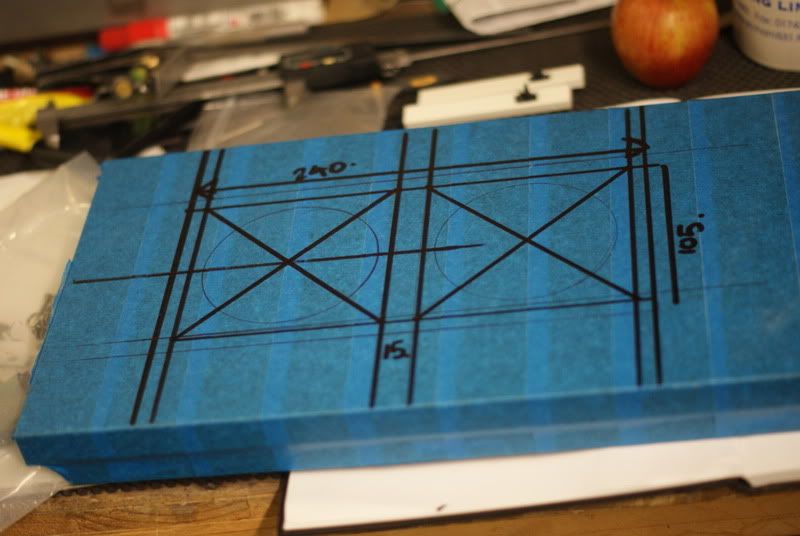

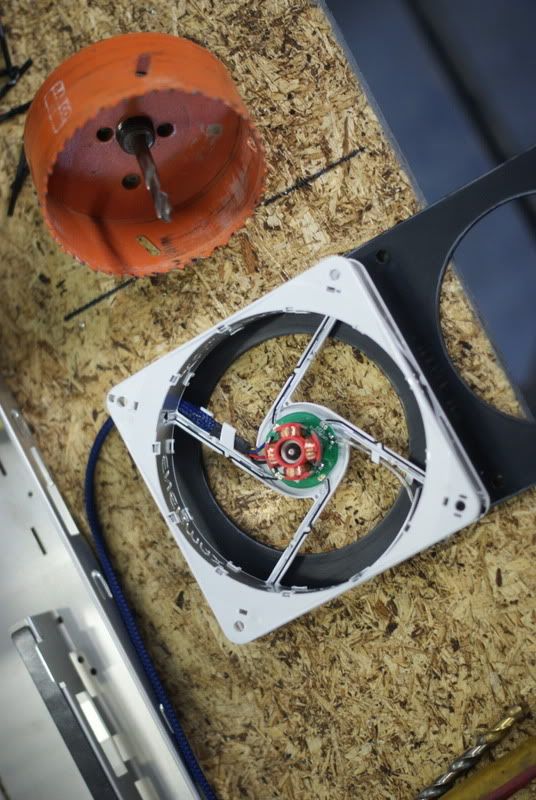

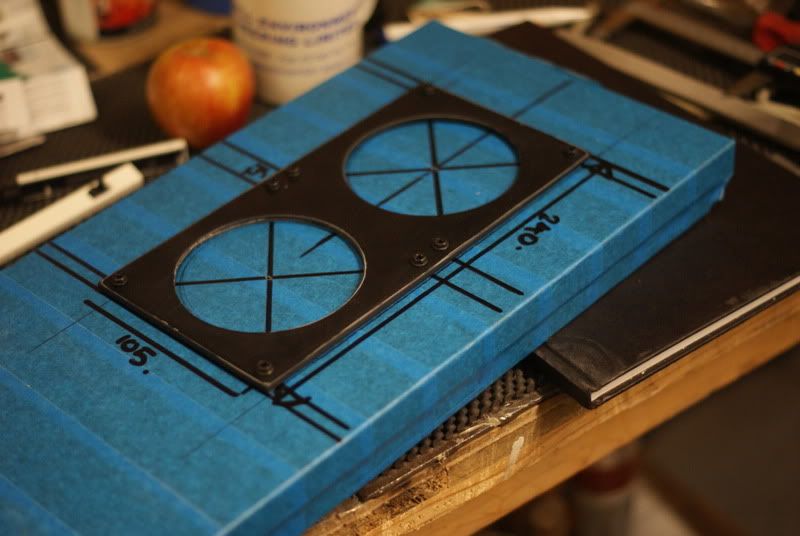

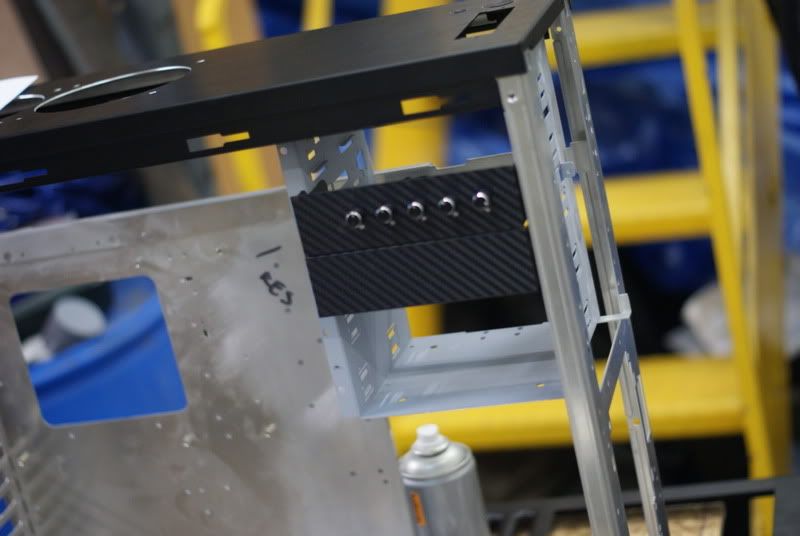

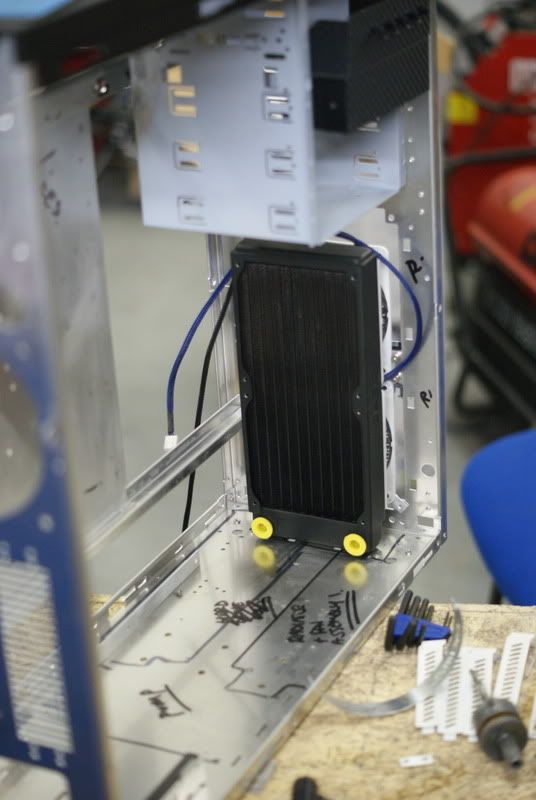

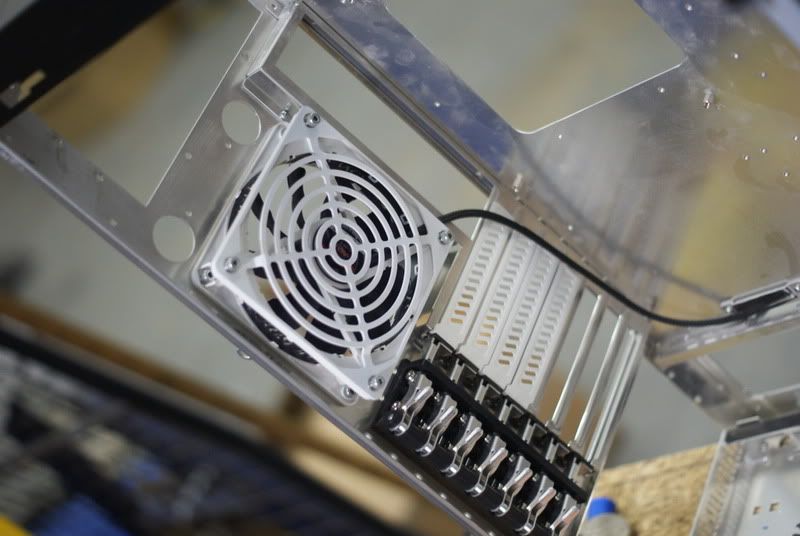

Next up, the 5 1/4" drive bay, I want it rotated 90 degrees as shown here.......

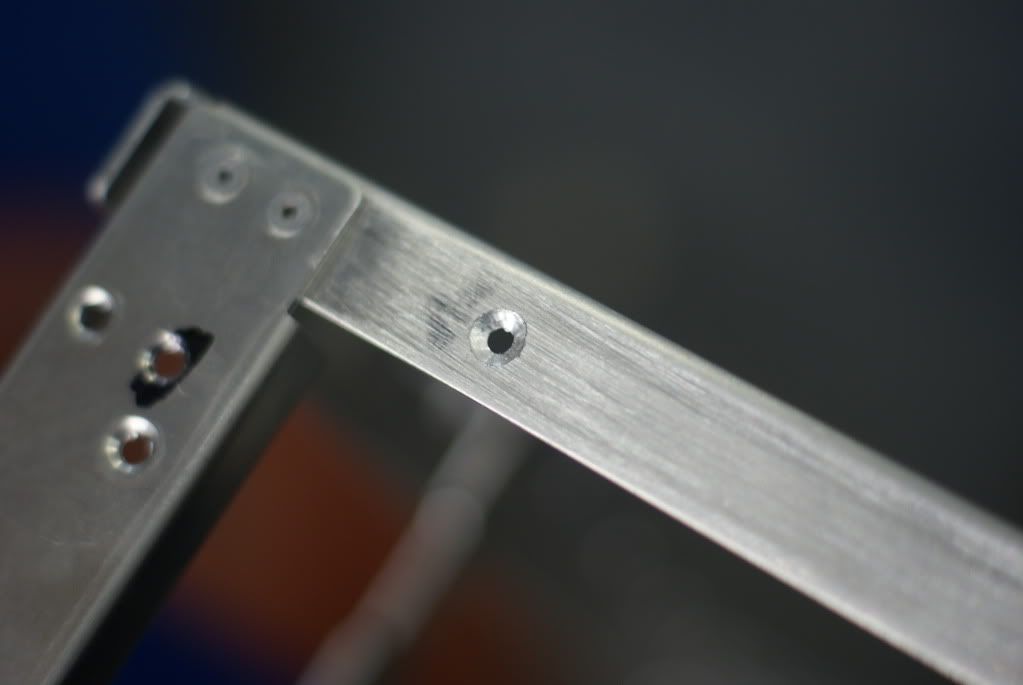

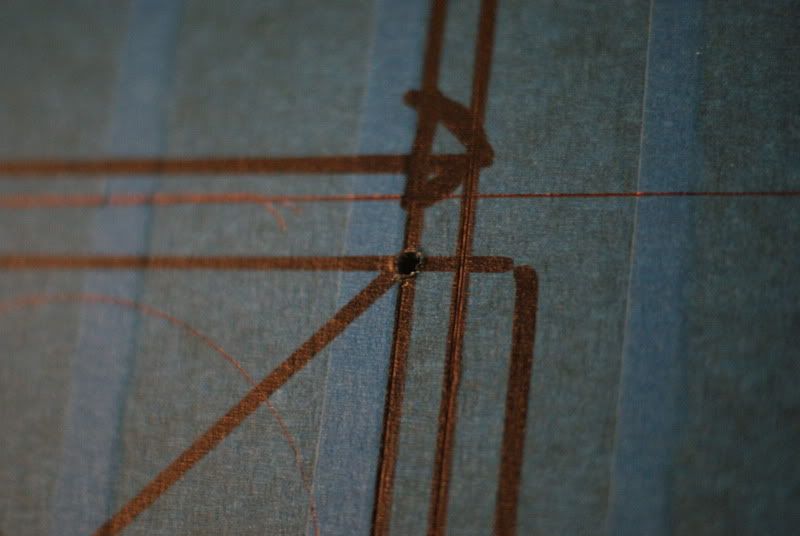

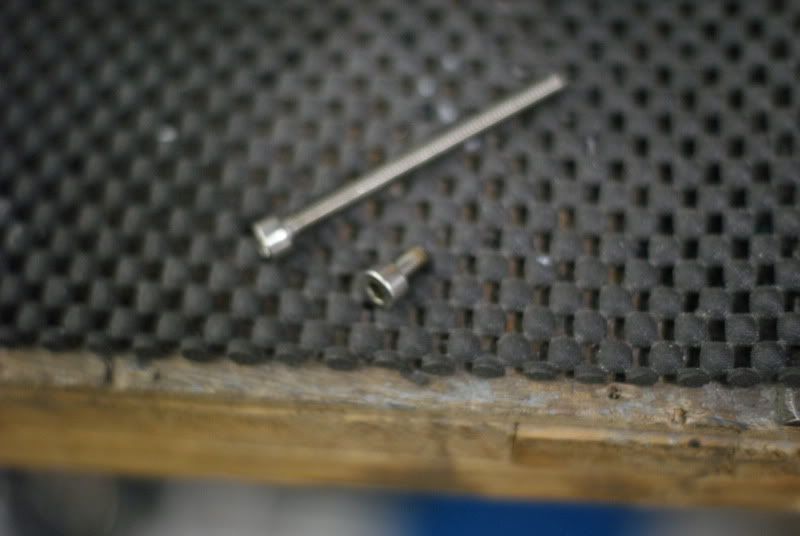

Simple enough, drill two holes in the frame...

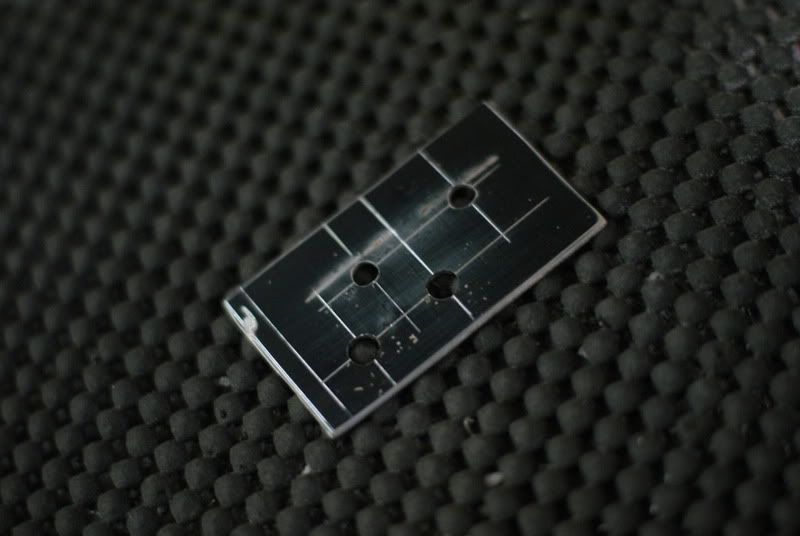

counter-sink the holes....

Done, one drive bay twisted around.

I need to get a slim-line optical bay then, I have 200mm width, but I need plenty of room on the back for the cables, as well as the front, the drive it sitting back from the extremity of the side panel, so there is a few mill there for when the drive is installed, obviously the drive doesn't sit in all the way flush to the bay, it juts out about an inch. I'll have to see....

Thanks for looking.

.

.