that lacing look well sweet

Thanks!

Reservoir Modding

The Problem

Reservoir Modding

The Problem

A few years ago (probably ~2007) I bought this nice little reservoir for my Eheim 1046.

It's a very handy little thing, and it's built like a bloody tank (seriously, you could bludgeon

somebody to death with this).

However, back then Aquacomputer had not yet fully jumped on the G1/4" train and was still

using G1/8" in many of their products (as they had since their inception).

This requires a rather ugly and unwieldy adapter when wanting to use modern fittings, such

as the lovely blue Monsoon ones I've bought.

The adapter itself looks like this:

(click image for full res)

And with a fitting on it:

(click image for full res)

The Plan

The Plan

Well, it's quite simple really: Retap the hole to G1/4". However, this would leave me with a

slight problem: Naked aluminium exposed to the coolant. I will be using a corrosion inhibitor

in my loop, but I want to reduce the chance for corrosion to ruin the party by painting over the

naked aluminium and sealing the hole thing against the coolant.

Disclaimer

I'm well aware of what galvanic corrosion is and how it works (well, I'm not a chemist, but I have

a better grasp of it than most people I'd say). I'm not saying that what you're about to bear witness

to is a good idea or something you should necessarily try yourself. It's an experiment. If it works,

great, if not, I haven't lost anything since I have no more use for the reservoir anyway. But don't

anybody start panicking about corrosion please. I'm aware of the risks, I've weighed them and

I've made an informed decision to go ahead.

Protecting the Insides

Obviously we don't want to crash into the opposing inner wall with our drill.

(click image for full res)

The Drill and Tap

The Drill and Tap

The 11.80 mm drill bit with the G1/4" tap.

(click image for full res)

Improvising

Improvising

The 11.80 didn't fit into the drill bit adapter, so I had to improvise a bit. The adapter actually

belongs to a Bosch pneumatic drill hammer, but that thing is way too powerful for this sort

of thing, so I decided to go with this configuration. It worked surprisingly well.

Naturally I didn't just drill the G1/8" to 11.80 mm, but first to 9 mm, 10 mm and then to

11.80 mm (a 11 mm drill bit would have been handy, 10 to 11.80 is a rather large step).

(click image for full res)

Lubrication

Lubrication

I didn't have any actual lubricant specifically for this, so I just used some of the gun lubricant I have

laying around (both for drilling and tapping the thread). Since it's made for the high speed movement

of a gun action, it works very well for this.

(click image for full res)

Tapping Hole

Tapping Hole

The 11.80 mm hole before threading.

(click image for full res)

Threading

Threading

And after cutting the thread. You can clearly see how thick the walls are on this thing. That's

why you need to lubricate very well. Otherwise the drill just blocks.

(click image for full res)

Test Fit

Test Fit

As expected, much better.

(click image for full res)

(click image for full res)

Protection

Protection

Alright then, let's paint that sucker! I did one coat of etch primer and two coats of paint.

Obviously I can't really do proper surface treatment within the thread, or put on too much

paint since it will just get stripped off by the fitting's thread anyway, but this should work

well enough to prevent the coolant from getting to the naked aluminium.

(click image for full res)

And on the inside:

(click image for full res)

Painted

Painted

The coat is pretty thick and has bonded nicely to the surface.

(click image for full res)

Done

Done

The Monsoon fitting hides the paint job very well, and it goes in and out without

strippint the paint off the threads (there were two small patches of paint stripped

off, but I've covered those with the Humbrol enamel paint and things are nice and

sealed now).

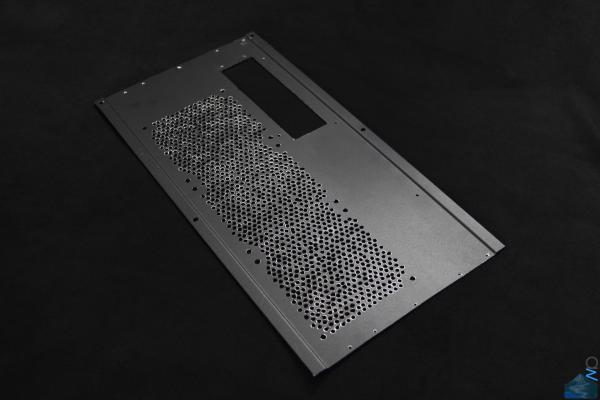

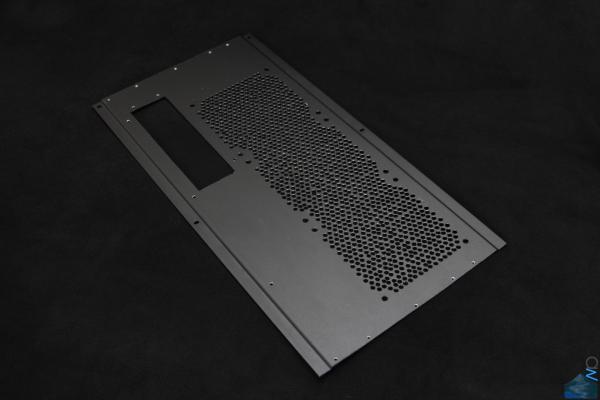

As you can see, the reservoir has sustained the occasional scratch over the years.

(click image for full res)