Excalabur50

Well-known member

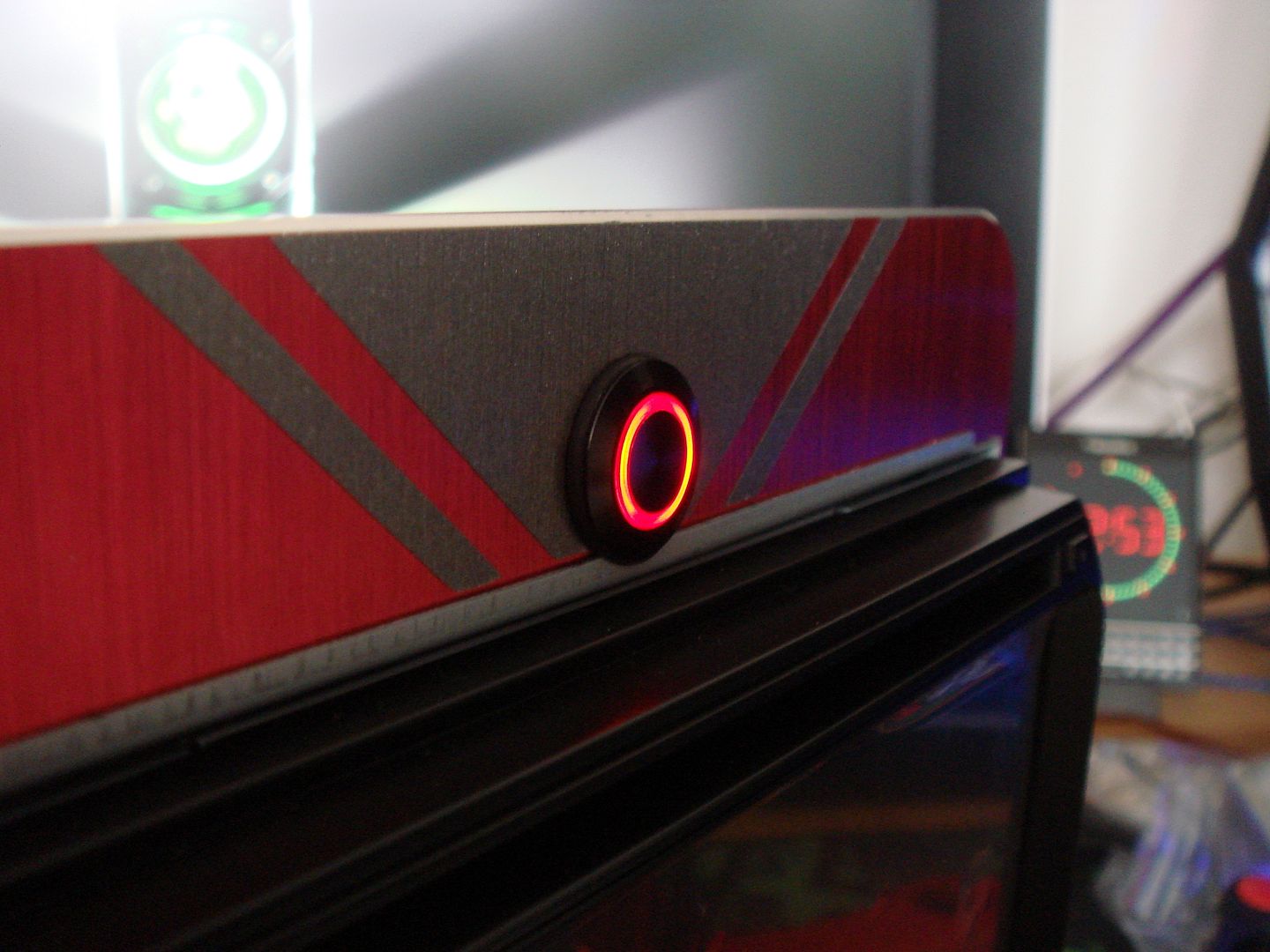

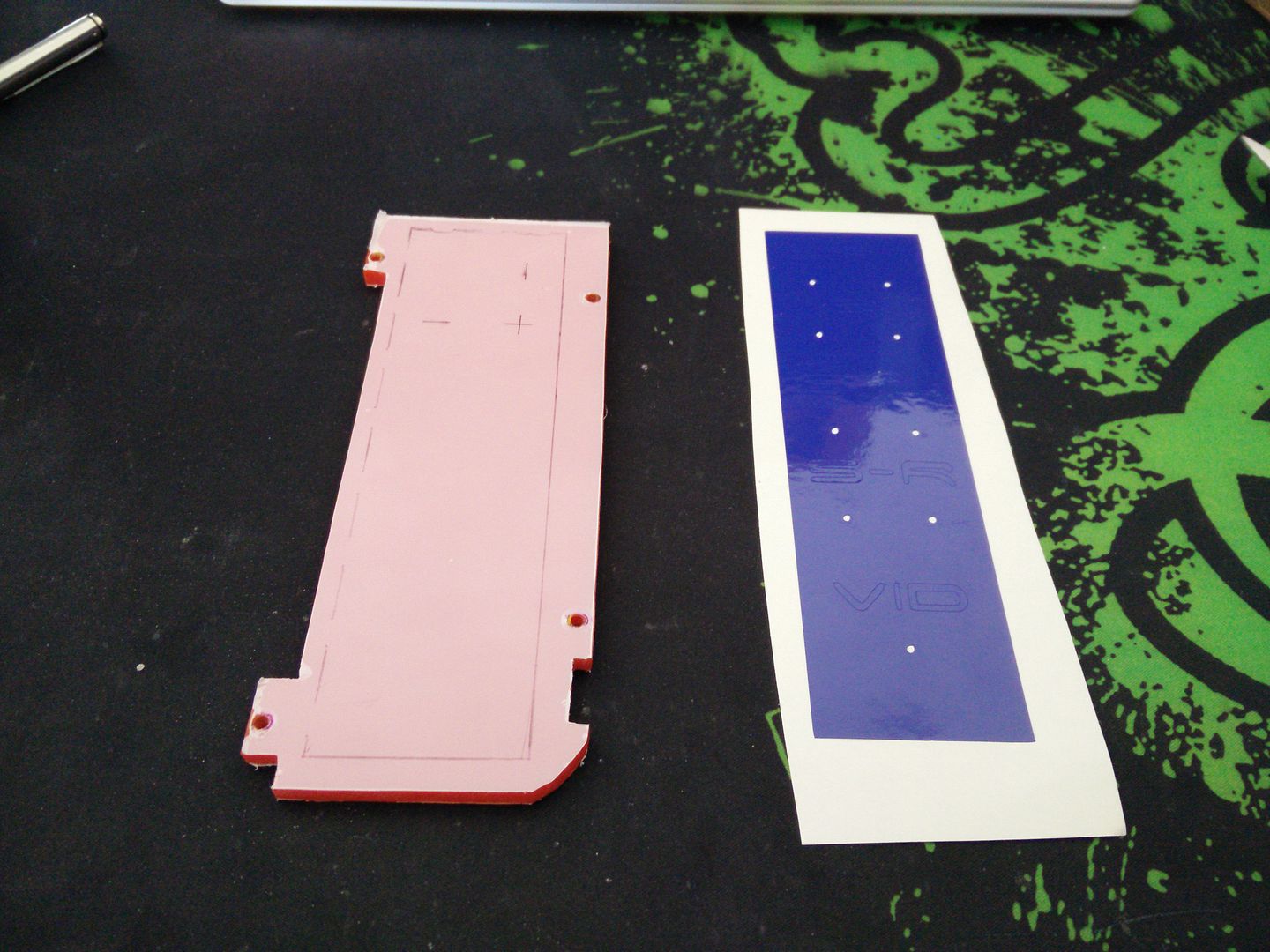

Yes that does look good lucky break on that one

Last edited:

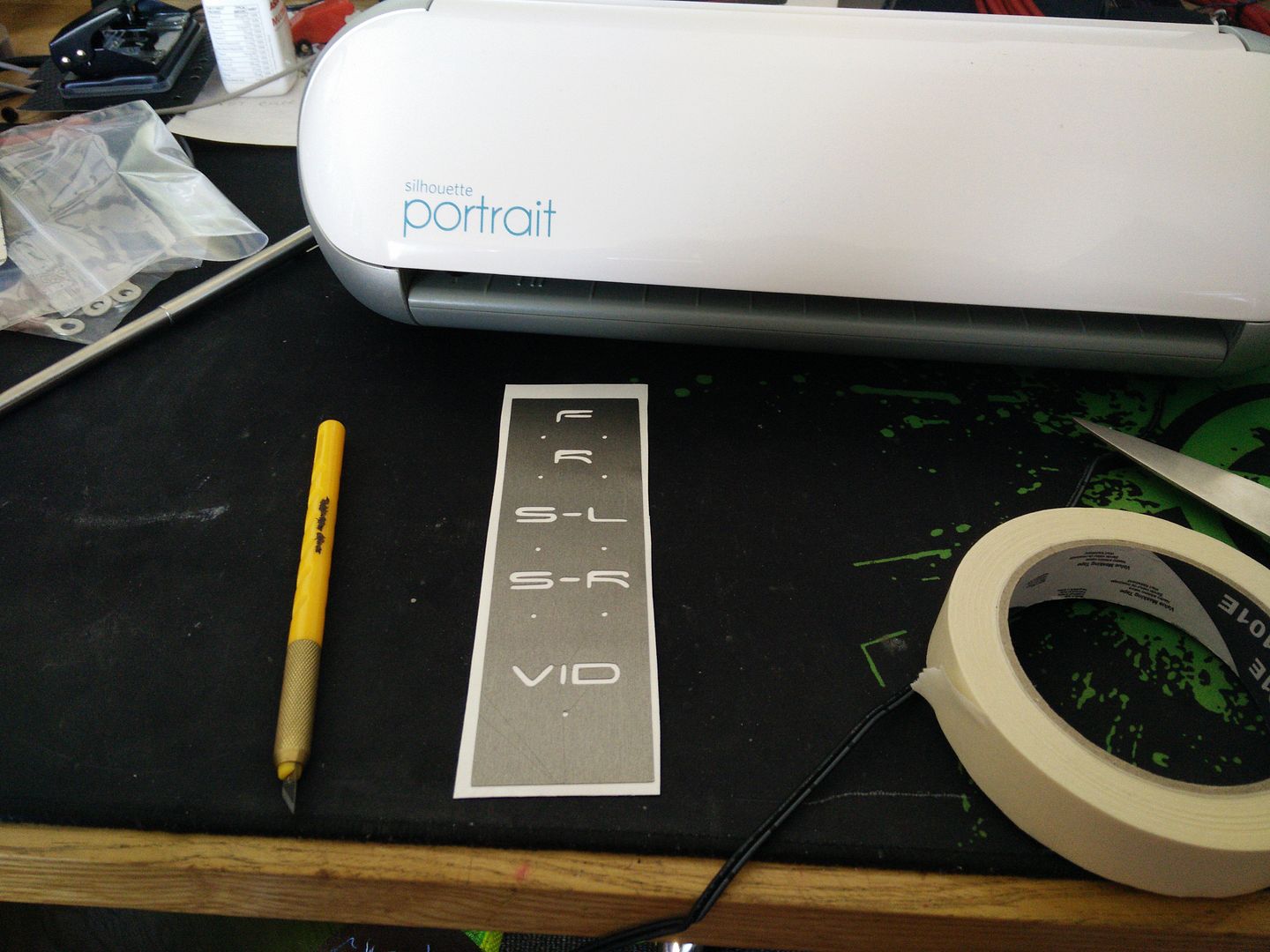

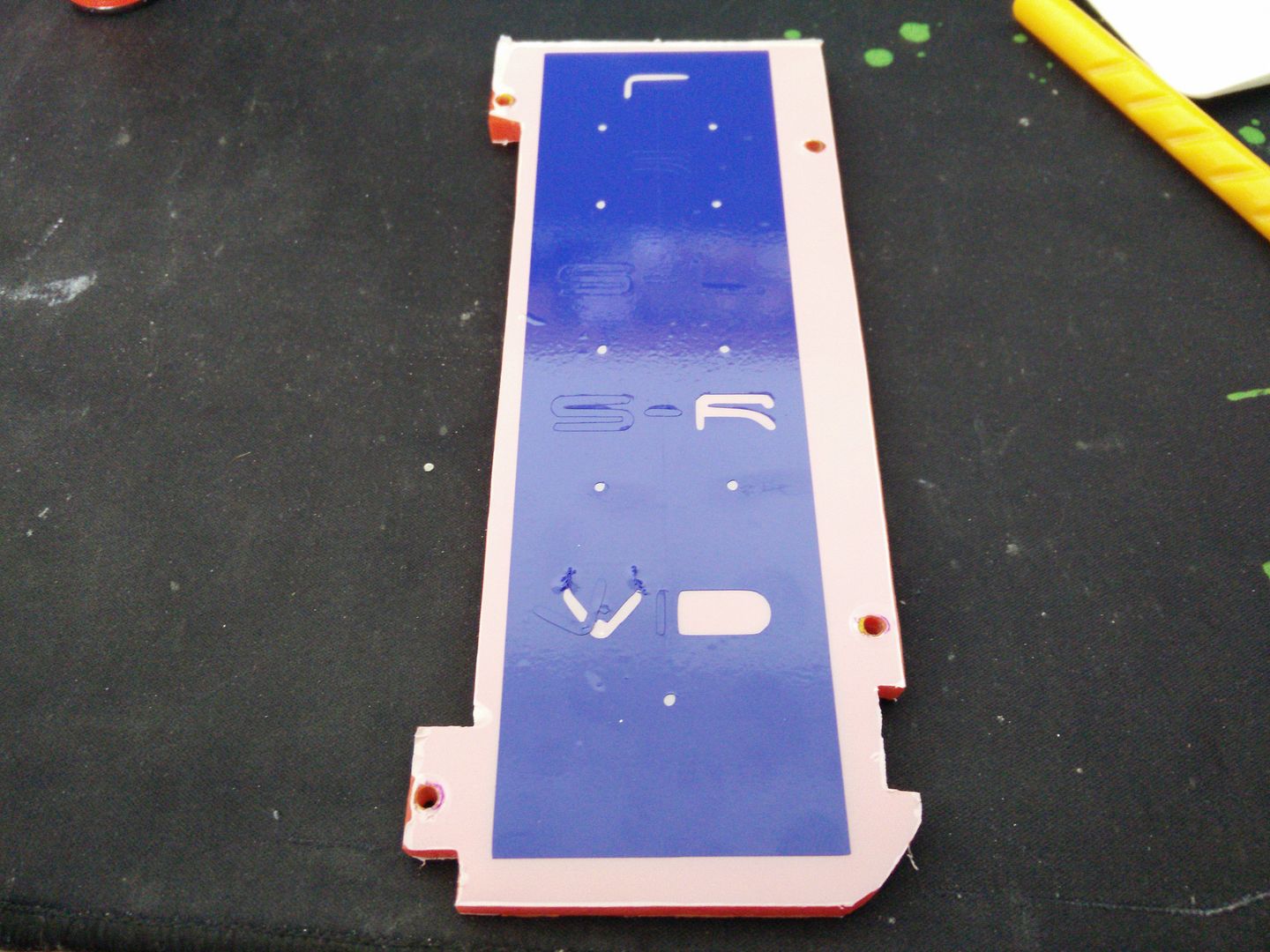

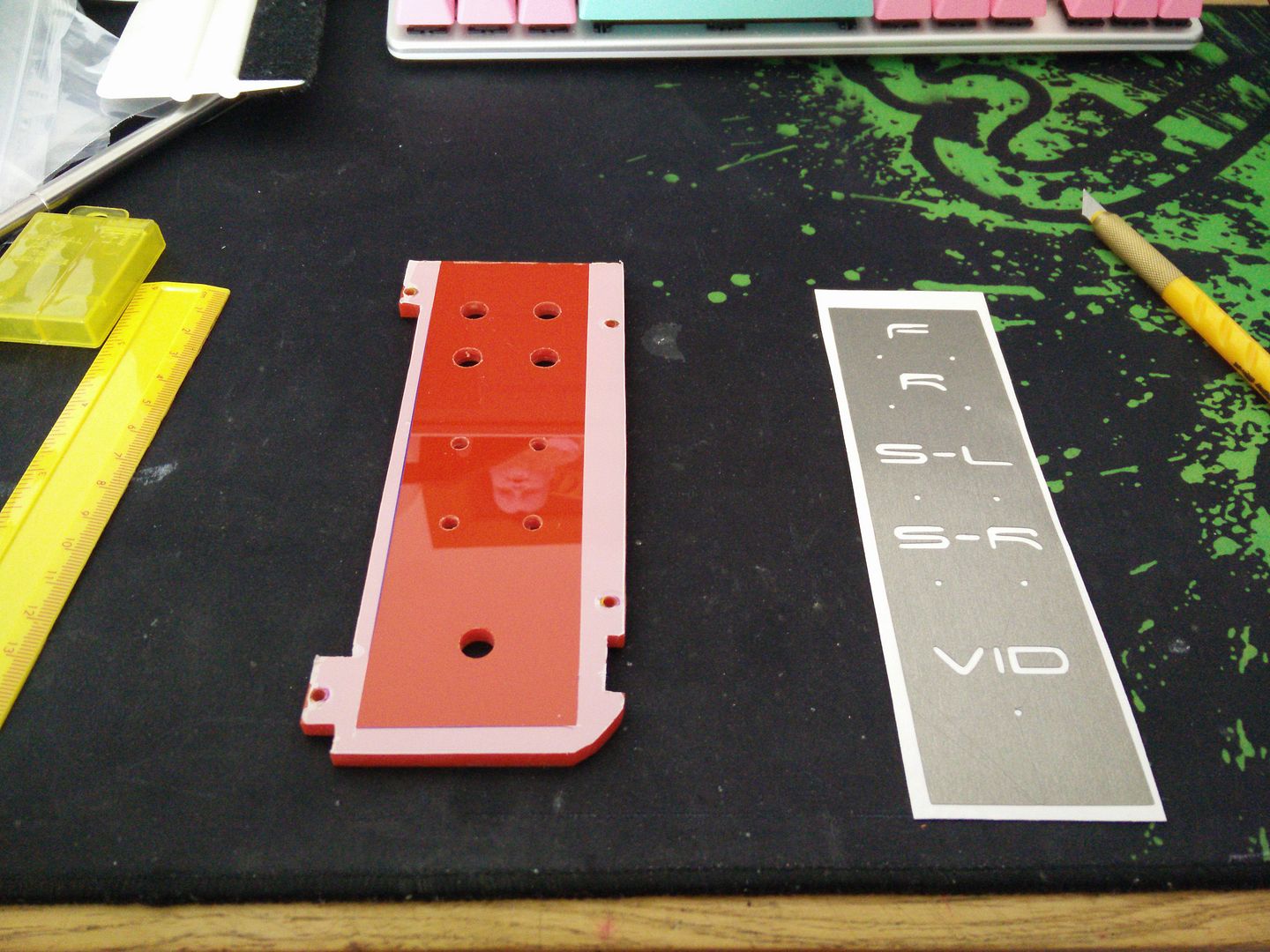

Not a fan of that font. The F looks like the R

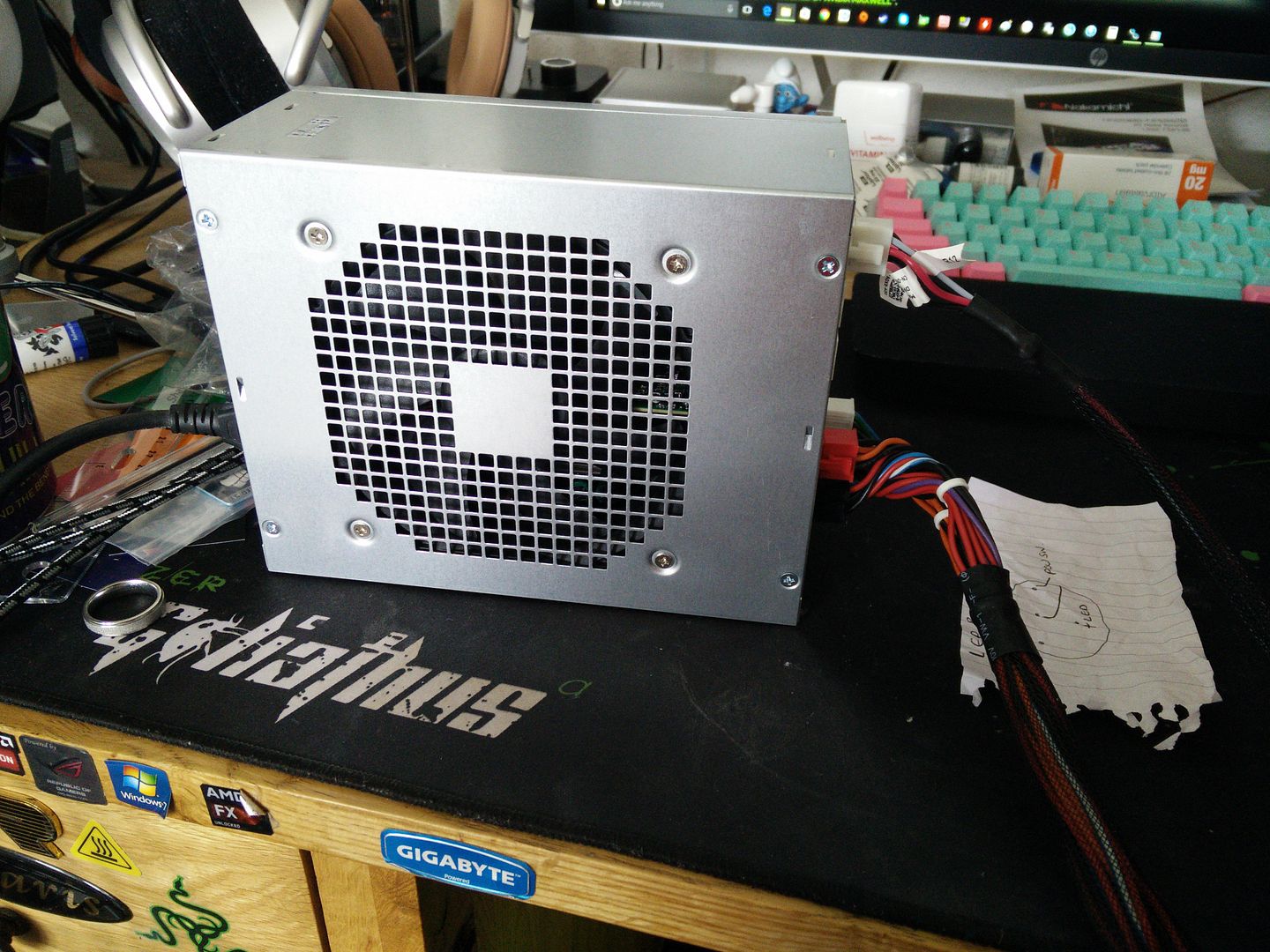

How do you feel about his pink custom key caps

The keycaps are awesome.

Not a fan of that font. The F looks like the R

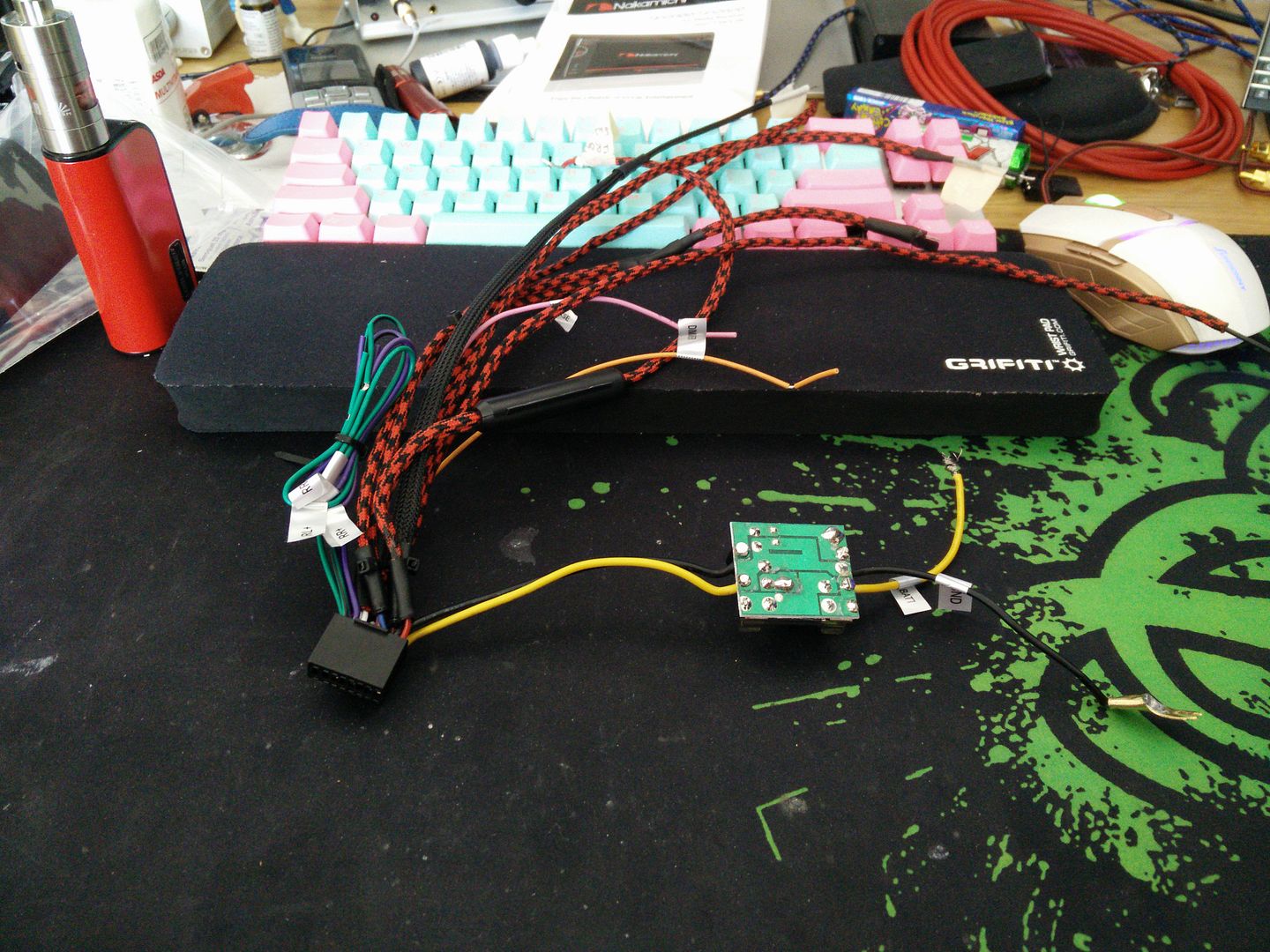

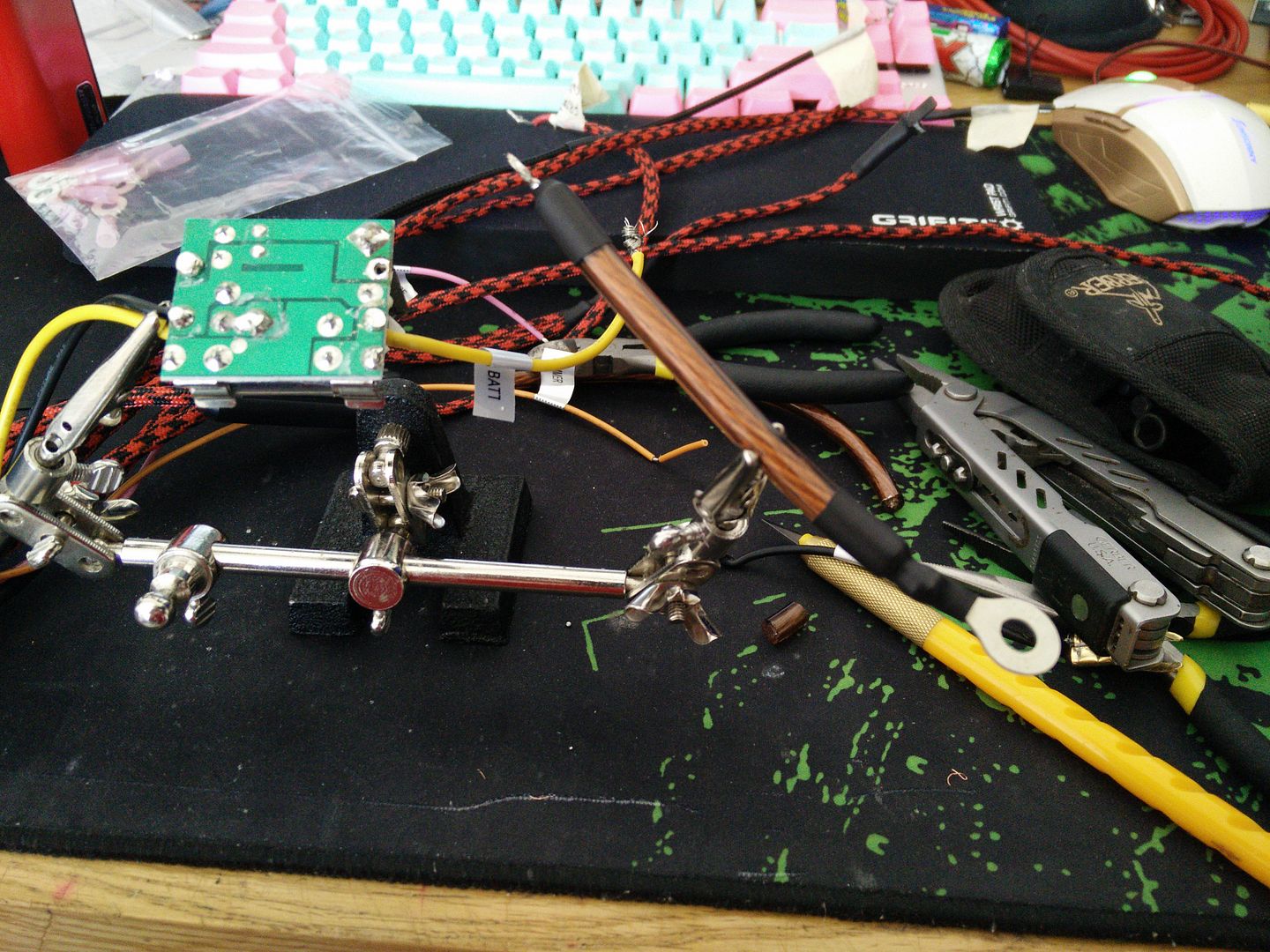

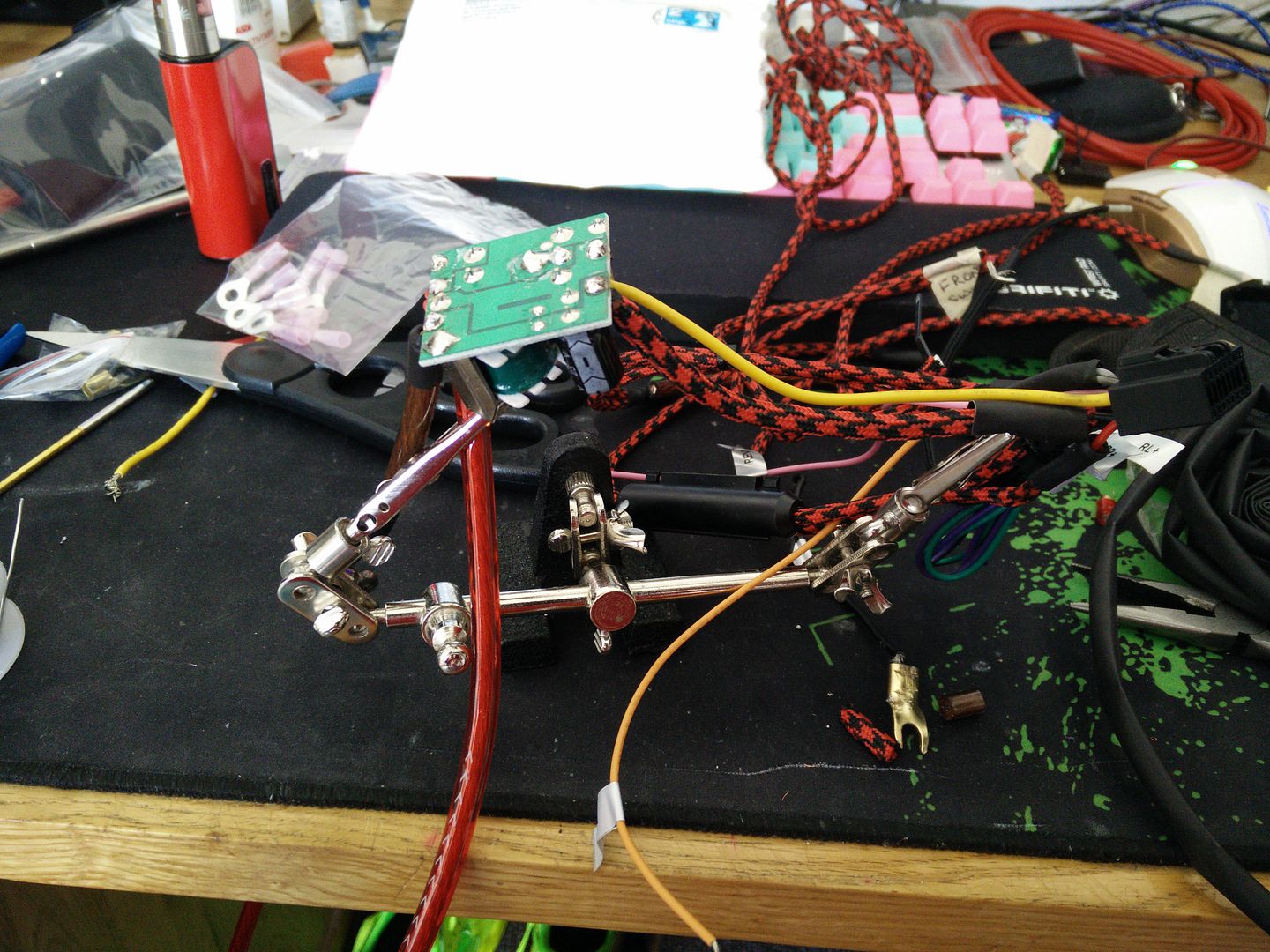

Do you have a background in electronics or have you just learnt it through experimenting?

Interesting stuff, have been interested in car audio for a while but never gone further than following various people on YouTube such as Steve Meade.

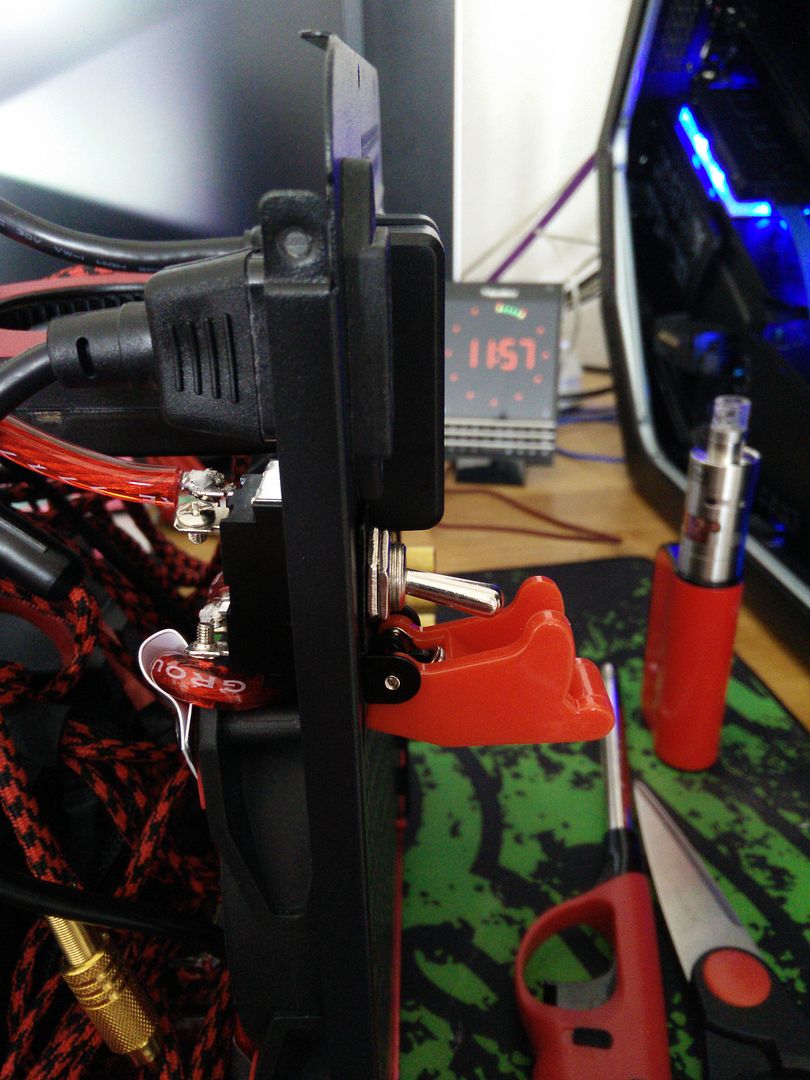

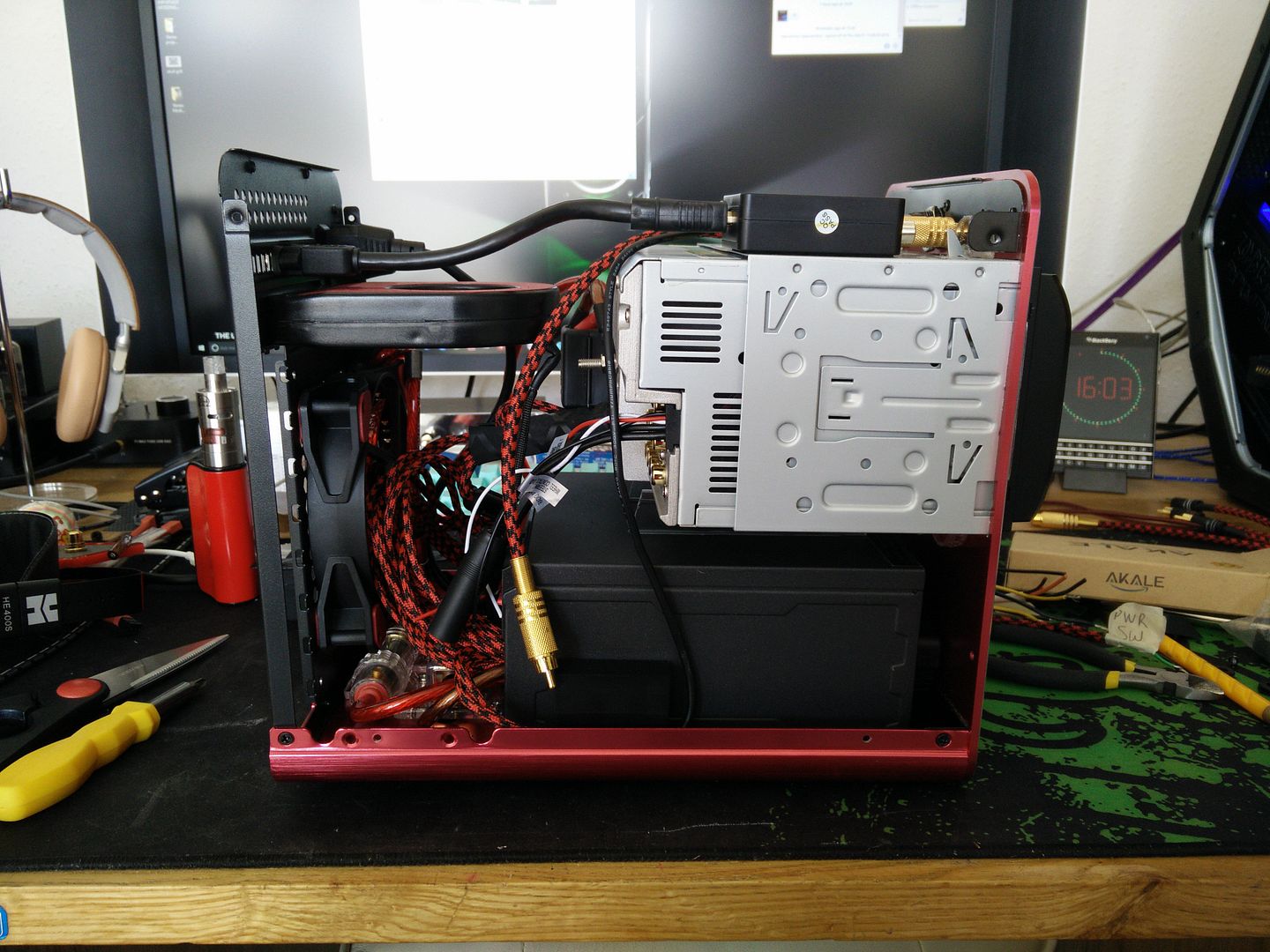

Sure is a tight fit.