AlienALX

Well-known member

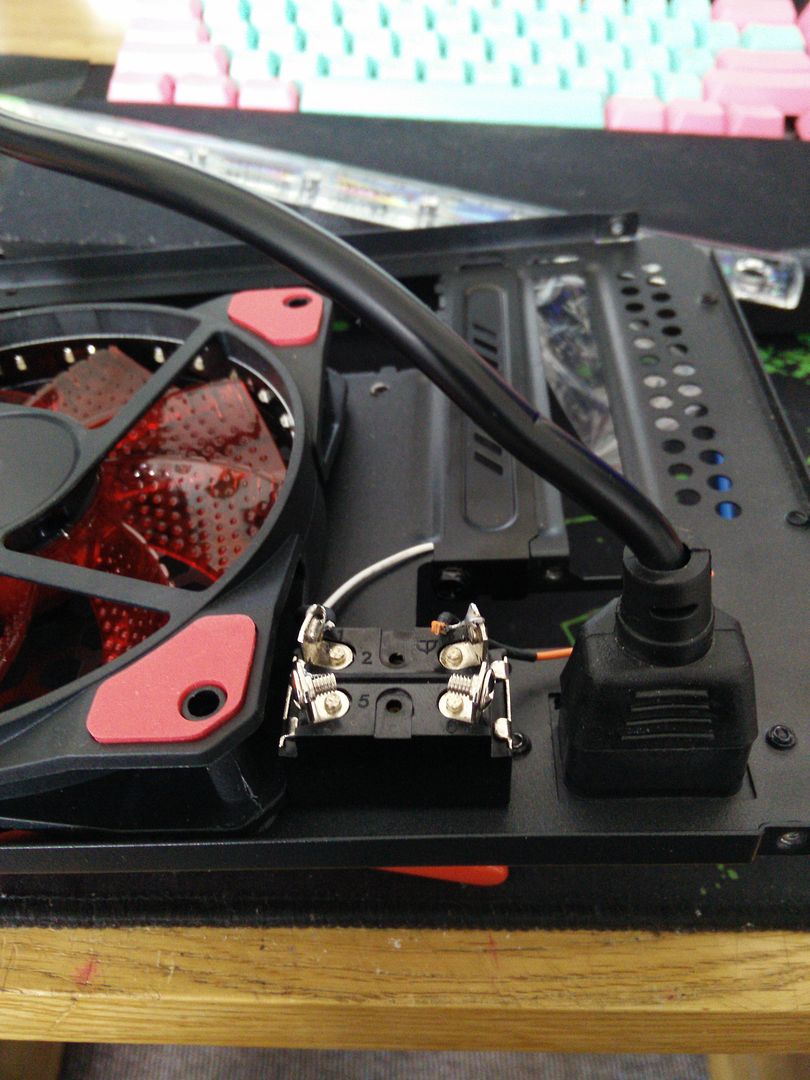

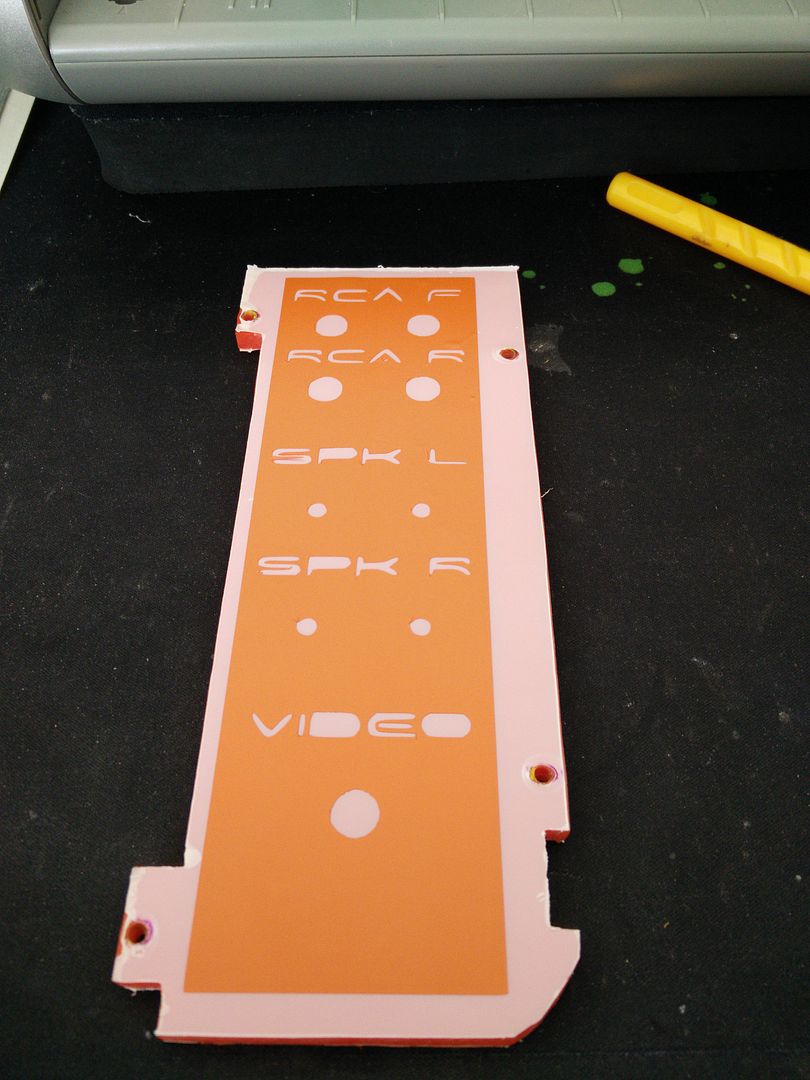

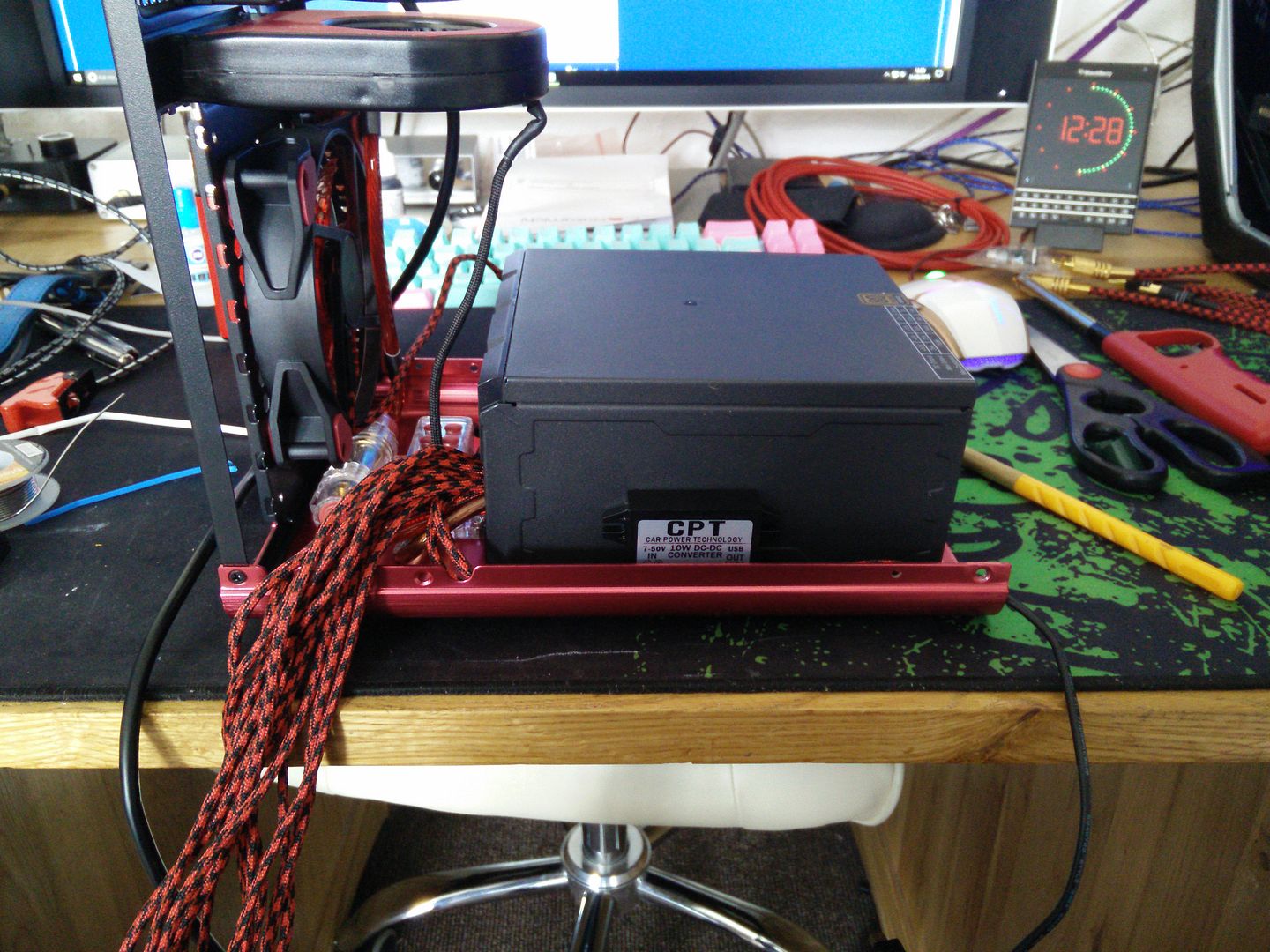

All of the component cables are finished  this includes 4 x RCA audio and two video. One video to go into the back panel and one to go into the AV-HDMI box.

this includes 4 x RCA audio and two video. One video to go into the back panel and one to go into the AV-HDMI box.

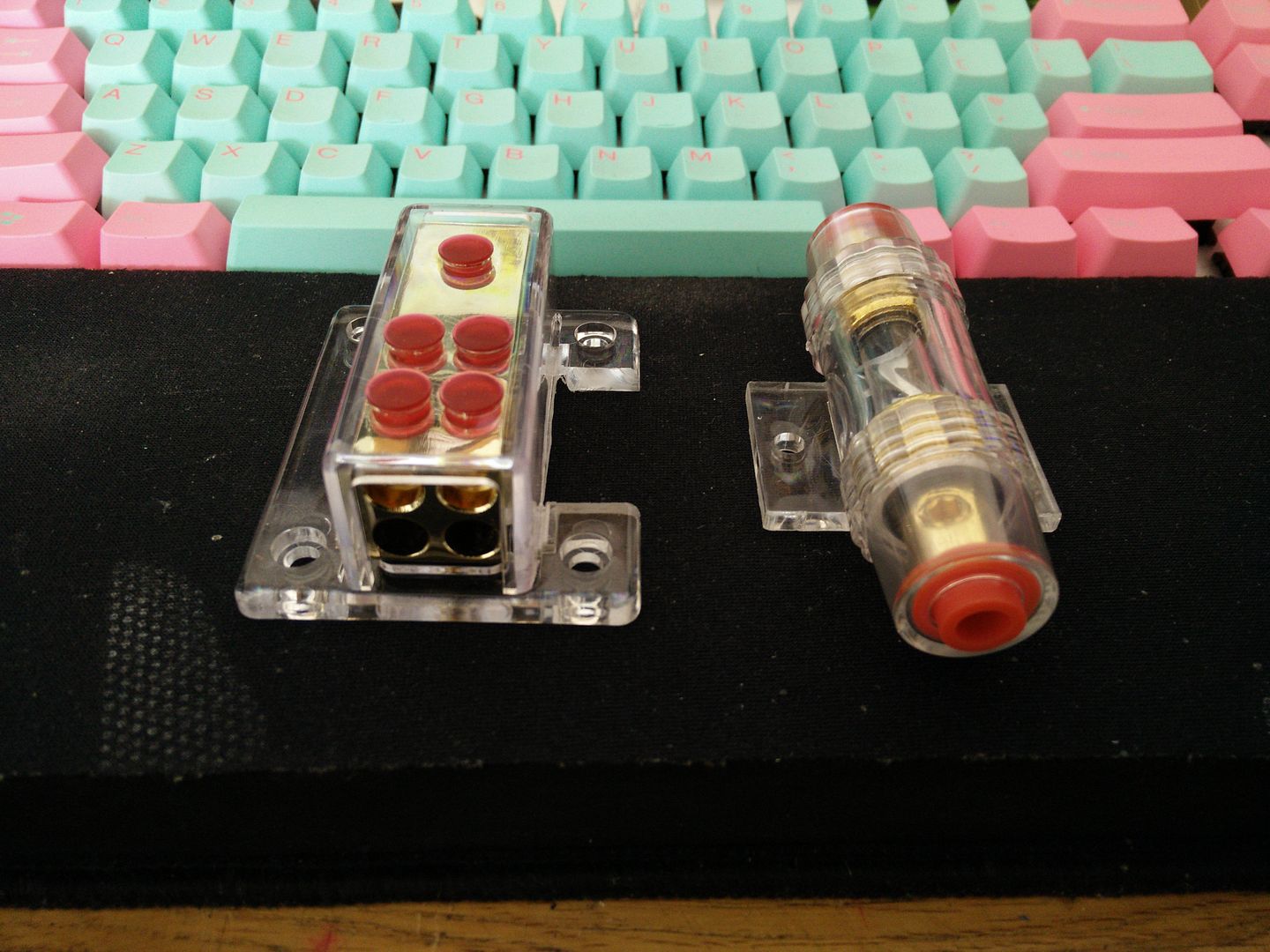

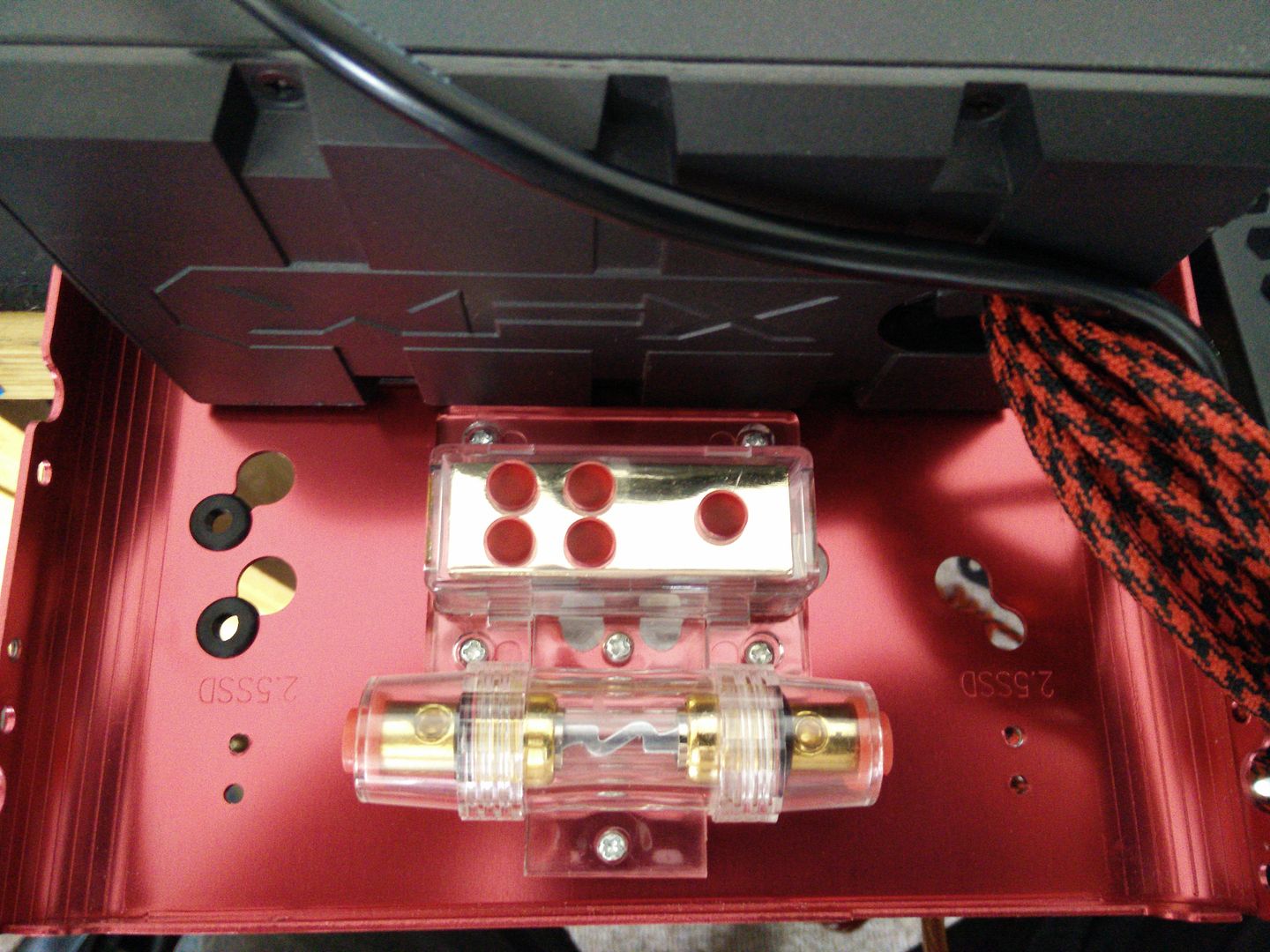

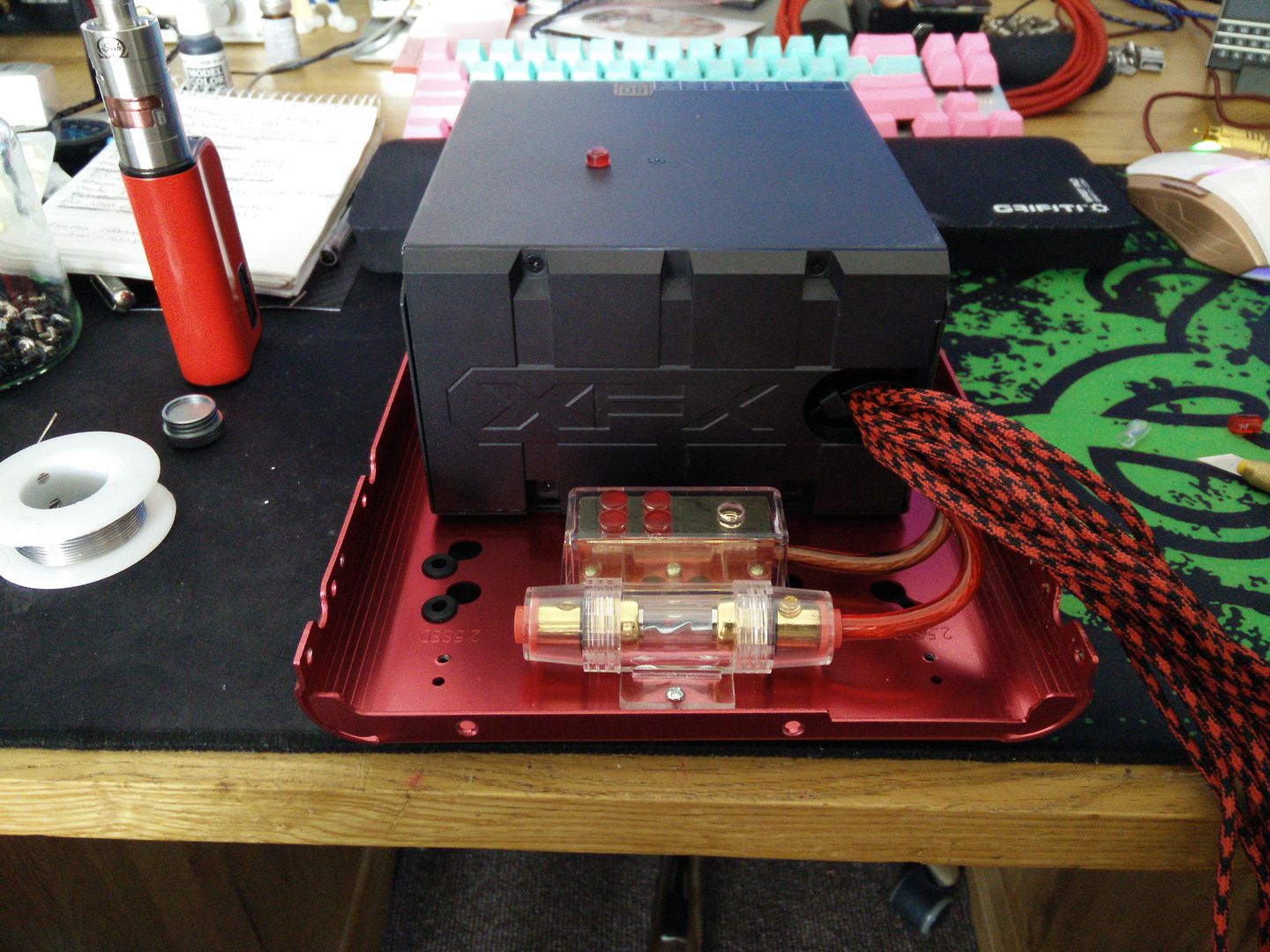

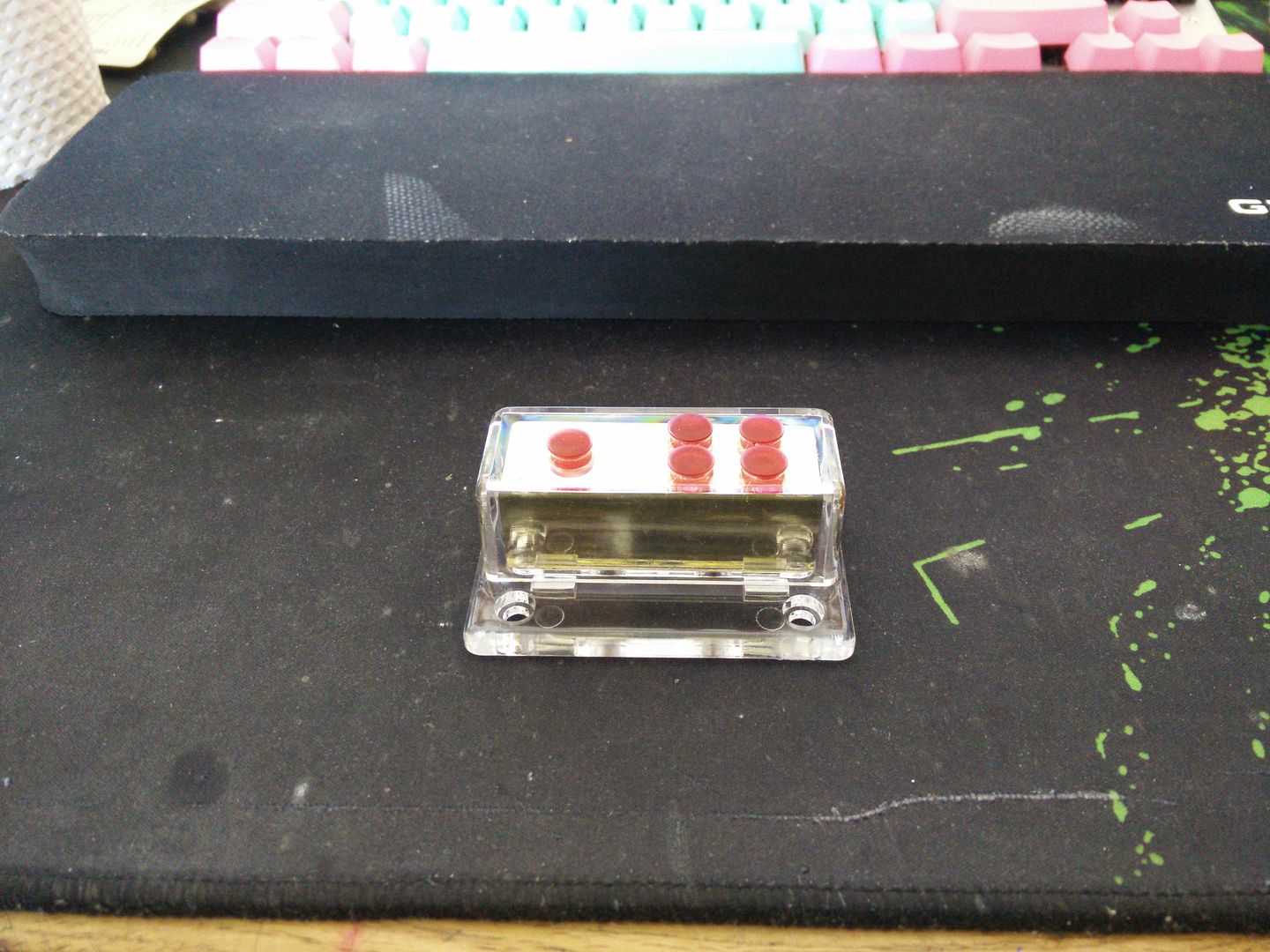

And the ground distro block came. I will paint the red caps black

Maybe later tonight I will make up the speaker cables that go to the back panel, then all of the wiring for that will be completed

And the ground distro block came. I will paint the red caps black

Maybe later tonight I will make up the speaker cables that go to the back panel, then all of the wiring for that will be completed