G-Dubs

New member

Looking good, can't wait to see more.

I've read on another forum that painting Scythe GT's can unbalance them, your saying that's not the case due to them being thick bladed? You not had any problems painting them in the past I assume?

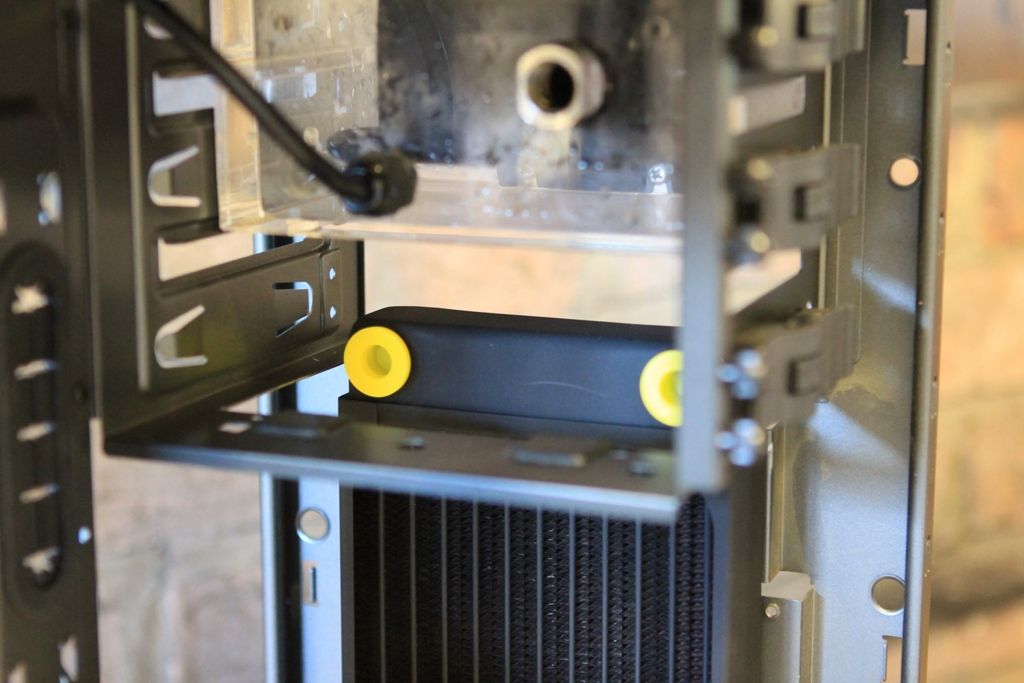

I'd also read that somewhere, but put it this way, over the years i've painted and used countless sets of the Gentle typhoon fans and never ever had a problem. The Skeleton rig i'm currently running has 3 of them on the 360 rad with the fan blades pained in a nice thick lusterous coat of bright yellow. It runs on average 5 hours each evening and all day at the weekends and has done for nearly 2 years with no problems.

So basically, despite what you might read, it's not a problem.