AdrianD2

New member

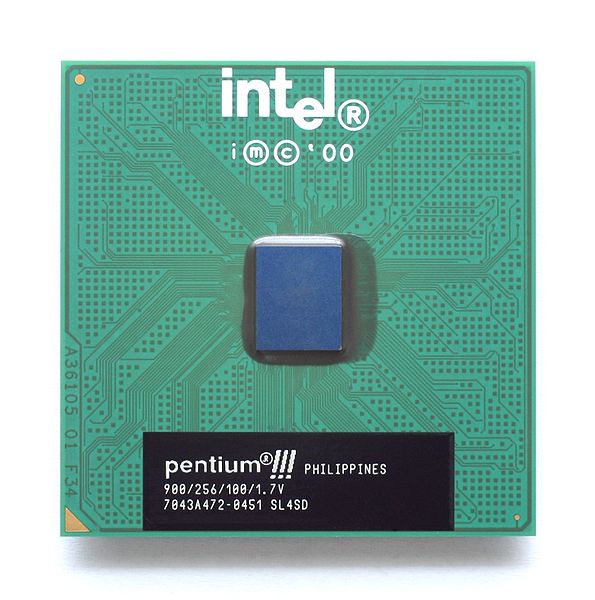

OK, so processors have that metal heat-shield protecting all the goodies inside, right? You need a heatsink to dissipate heat from the CPU so it doesn't fry.

What I do understand is why Intel and AMD haven't replaced that heat-shield with a direct contact heatsink? There would be no need for TIM, and I think it would be more cost efficient and obviously cooler. I understand that some people want their own heatsinks and watercooling and all that, but I'm talking about the home PCs and might I dare say... MACs!!!

I think this would be great for the Atom processors and laptops!

I am talking about the metal bit on top, just in case you didn't understand

http://img.tomshardware.com/us/2007/10/29/hitting_4ghz_with_air_cooling/01-start_cpu.jpg

What I do understand is why Intel and AMD haven't replaced that heat-shield with a direct contact heatsink? There would be no need for TIM, and I think it would be more cost efficient and obviously cooler. I understand that some people want their own heatsinks and watercooling and all that, but I'm talking about the home PCs and might I dare say... MACs!!!

I think this would be great for the Atom processors and laptops!

I am talking about the metal bit on top, just in case you didn't understand

http://img.tomshardware.com/us/2007/10/29/hitting_4ghz_with_air_cooling/01-start_cpu.jpg