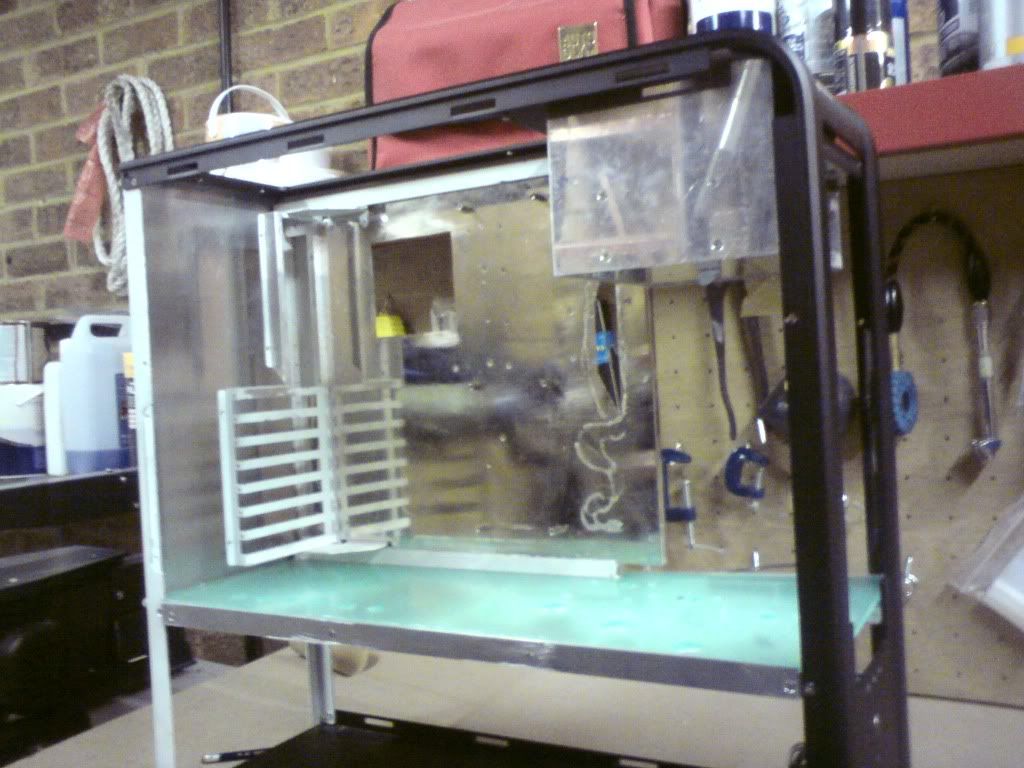

Thanks AA but im not sure where im getting it cut yet. All the internals are going to be done power white, the outside of the case (due to all the filler and smoothing work) will be painted.

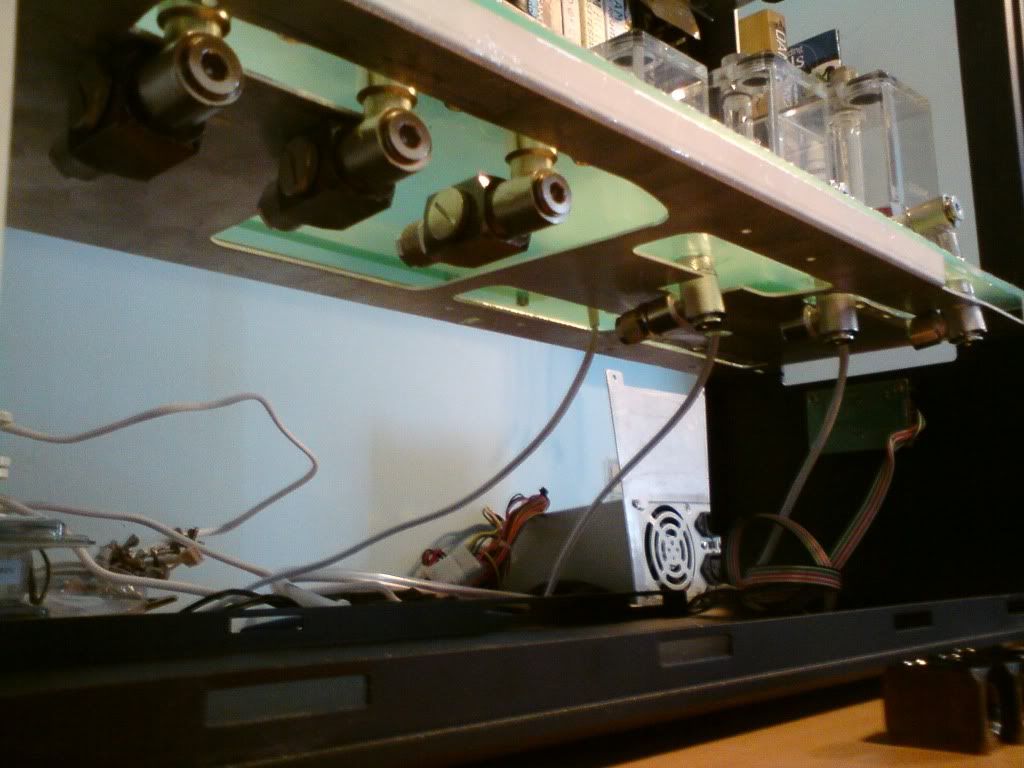

SA - The whole idea of lengthening the window is so you can see all the pumps, that window desing is not final yet, if you look a few pages back you will see in my original desgin (2008) i had it so you would not see the hdd cage, have a look and see. i know what you mean tho i may change in to suite, but its defo going to have to show off the pumps, infact ill do another shop now... 5 mins.

SA - The whole idea of lengthening the window is so you can see all the pumps, that window desing is not final yet, if you look a few pages back you will see in my original desgin (2008) i had it so you would not see the hdd cage, have a look and see. i know what you mean tho i may change in to suite, but its defo going to have to show off the pumps, infact ill do another shop now... 5 mins.