Permafrost

Compo Whore

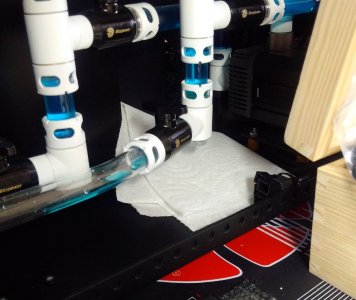

The filters took about 10 days from my order, I used the FedEx option:- FedEx (Zone D)(3-5days) (I live in a remote part of the uk)

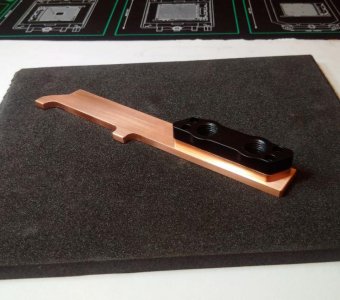

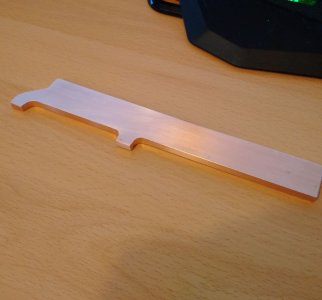

I did think on using a ram waterblock but as my M.2 is mounted directly flat to the board and will be nearly all covered by a GPU, I need a waterblock that extends out past the side of the motherboard/ GPU to give me space to fit the derlin block that the 1/4 fittings and the pipes attach to.

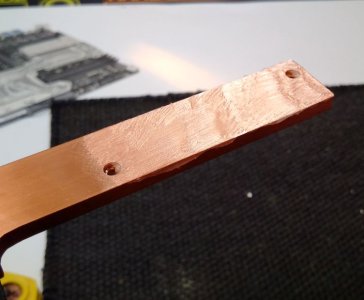

The 80mm M2 will need about 120mm of flat bar to cover it and reach the mounting screws I am planning on using and then I will need about another 60-80mm to fit the block/ pipes to. All in I think the overall length of the heatsink copper bar will be in the region of 200mm.

i was asking from caselabs themselves

wow sounds like you're putting a lot of work into the SM951 alone, i would of thought it would be easier to get an intel NVME 750 ssd instead.