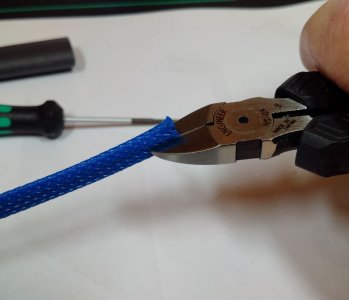

I thought I would make up the 24 pin cable from the PSU to the rear of the motherboard over this holiday weekend. Starting this morning I cut the sleeve and cable ties off the cable that came with the PSU.

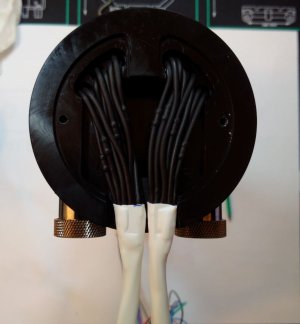

First thing I noticed was 3 capacitor type things which were under the sleeve before and out of sight. I also noticed that the 2 part connector that plugs into the PSU was not 24 pins, it was 28 pins which, with a lot of crossing of wires and several, 2 wires into one then terminated in a normal 24 pin male connector that would plug into the motherboard.

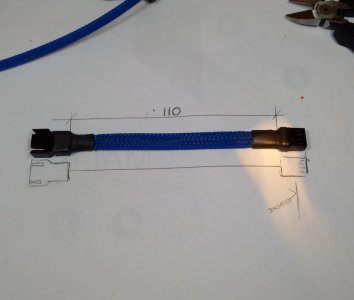

I wanted this cable to be neat but with all these extra wires and capacitors it did not look like it could be, so I decided to shorten the supplied cable to contain all the crossing wires in the PSU area and fit individual sleeves to try and smarten it up as best I can.

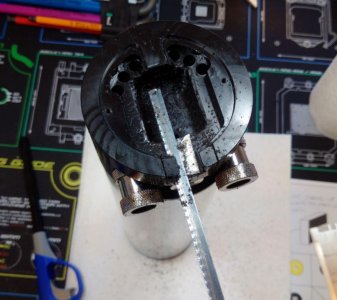

To do this I had to take the connectors that fit into the PSU off so that I could get the shortened sleeved wires connected up with the minimum of twisting/ crossing.

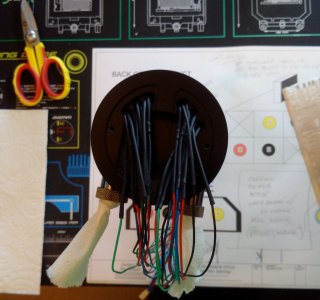

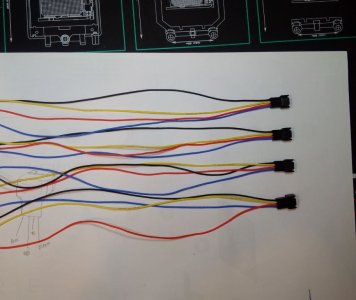

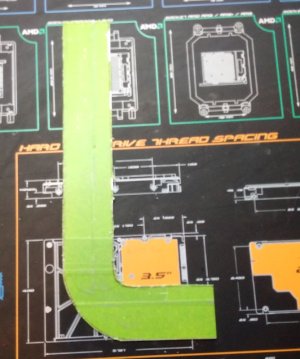

To take these off like this also meant I would have to do an accurate pin out drawing. I used cable ties around one wire at a time (to ensure I made no mistakes tracing a small wire through a bundle of 28) and established what went where.

It took a while but it was worth it and I have put a screen shot of it below if it is of any use to any other Super Flower 1600w modders.

Once fitted to the PSU I went over all 24 pins with my multi-meter and they all matched the 24 pin outputs stated in the Super Flower manual so all good

.

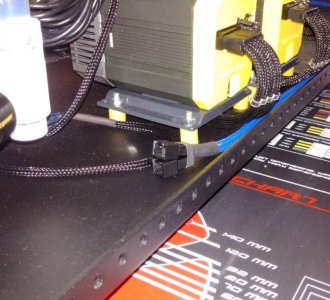

A couple of cable ties and its about as neat as I can make it, the wires in this standard cable are 16awg, quite a bit thicker than the more normal 18awg gauge. (I think they may be this thick gauge because judging by the markings this cable is also used on the 2000W Super Flower 8Pack Edition PSU)

It means you cant get the sleeve into the end of the connector, it just wont fit. Heat shrink would also look untidy due to the way some pins have 2 wires going in opposite directions.

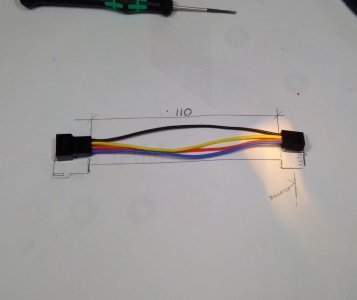

Thankfully this short cable will be covered up by the peripheral, 8 PIN MoBo and the GPU power cables. Now I can make up, what will basically be an extension 24 pin cable, which will be easier to make with pin 1 going to pin 1, pin 2 to pin 2 and so forth.