stepster - it's not patience I need its time to do it, work hours are getting silly recently and I'm having maybe 8 hours at home and most of that I need to sleep. Its the driving thats killing me, a daily commute of over 4 hours and 250 miles round trip on top of my 8 or 9 hour shift..but work's work. Cant turn it down really.

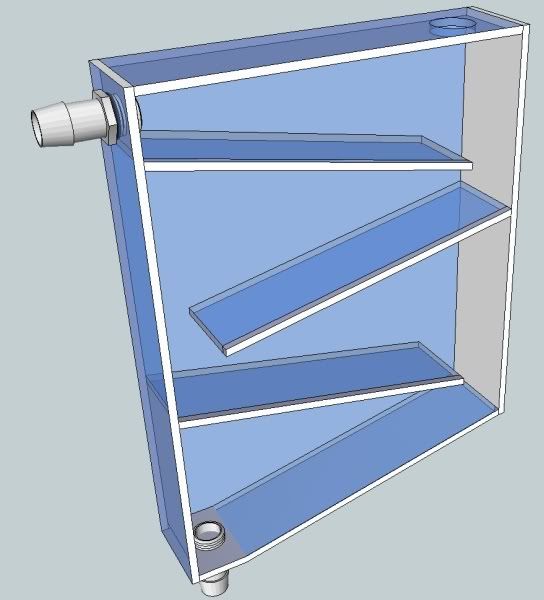

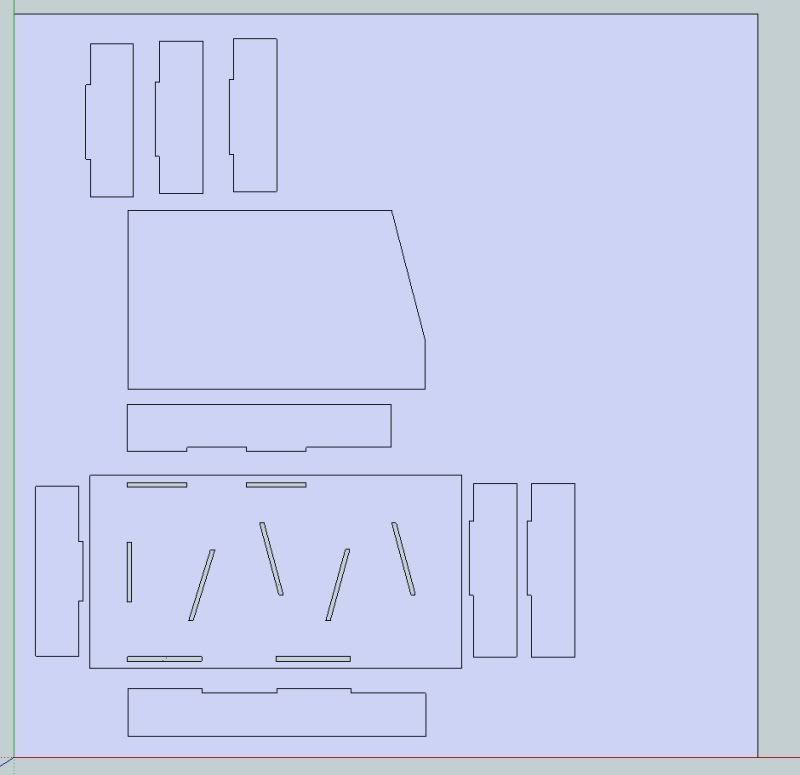

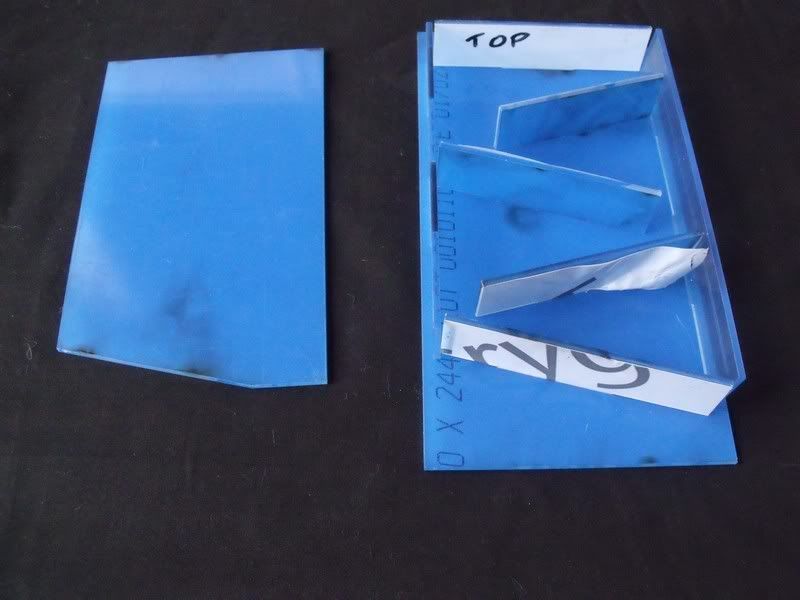

Another update, I've made quite a bit of progress on the res however I'm saving it all for the video, wouldn't want to spoil you too early.

However in other news I've picked up another sponsor.. Yay!

Let me introduce

Thank you very much for agreeing to supply what I required

My loop will consist of (although possibly not in this order)

D5 Pump - GPU - CPU - 120x3 Rad - Custom Res - Pump

These will all be fed using 1/2" tubing and I figured, new build, new barbs..Most of the gear has been bought and paid for myself however Specialtech agreed to provide a few items.

To go with my black and green case I figured it was only fitting (

) to match that colour scheme with some Bitspower Matte Black fittings and some 1/2" ID Compression Fittings to lose those pesky Jubilee clips.

My camera is flat so I've had to make do with just the one shot from my better half's camera until I get some better ones taken tomorrow. And as you can see I got a little bored...

I have 10x 45' Angles with 10x compression fittings to match, also 3 blanking plugs for GPU and Res fillport.

I'm hoping to get the res finished this week but I seem to only get an hour or so free at a time recently, just enough time to get out into the garage and start and then start tidying up again

Or I get all night, when I can't use power tools or make noise etc, still it gives me time to edit the hours of footage I already have stockpiled.

Until next time...