SEBAR

New member

UPDATE:

I finally got everything together for the time being and tested the system out. everything works good as far as the motherboard is concerned. Here are some pics of build.

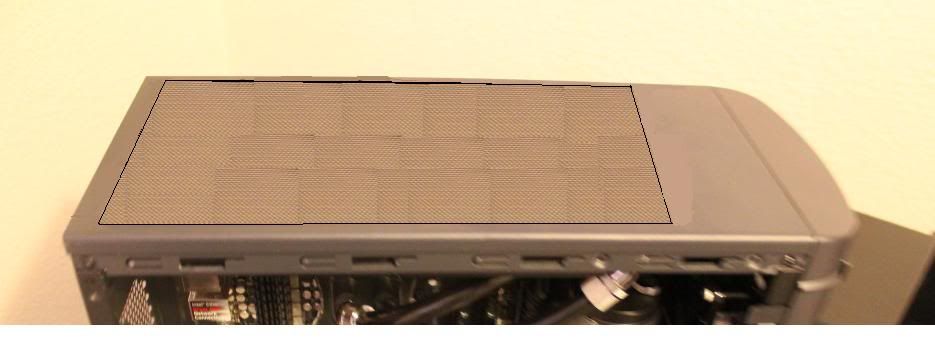

I decided to mount the rad to the roof of the case to make it easier for me to add the second 240 rad to the front when I get it. I have almost exactly 10 inches of space for the graphics card with this configuaration. There is no way I can get the 670FTW into the case like this so I will have to wait until I am able to get the shorter PCB 670 so I can put a water block on it and have plenty of room for the rad and tube res. I also installed black plexi cover over the PSU to hide the cable clutter.

To mount the rad in the roof I had to cut an opening to exhaust the air. I depated on how to do this for a while and finally came to the conclusion to cut out a semi circle and used some of the mesh from the side panel as a grill. It looks okay but I am not 100% happy with it.

The fans that are attached to the rad are the Scythe Slipstream slim fans. They are very quite but do not perform very well. With a prime 95 run I did last night the temps where in the high 50's and never went above 60. The front of the case I modified to accept two 120mm fans wich gives me the option to add another 240 rad.

The specs for this build are as follows:

Case- In Win Dragon Slayer mATX case

CPU-i5-3570K

Motherboard- Asus Maximus IV GENE Z/GEN 3

GPU- EVGA GTX 460

Memory- Mushkin 8GB (2x4GB DDR3 PC3-16000 9-11-9-27 Ridgeback

PSU- Corsair AX-650

SSD-Corsair Force 3 90 GB

HDD- Seagate Barracuda 360 GB 7200rpm

Cooling- XSPC RayStorm, XSPC EX240 radiator, Bitspower Water Tank Z -Multi Option 150 Reservoir, Swiftech MCP35B Pump.

Fans- 2 Scythe Slipstream Slim fans & 2 Enermax T.B. Silence

Future plans include adding another 240 radiator, adding a EVGA GTX 670 SC with a RayStorm 670 water block, Bitfenix Alchemy White LED, Mayhems Pastel Grape Red coolant and PrimoFlex Pro LRT Black Tubing -3/8in. ID X 1/2in. OD.

I finally got everything together for the time being and tested the system out. everything works good as far as the motherboard is concerned. Here are some pics of build.

I decided to mount the rad to the roof of the case to make it easier for me to add the second 240 rad to the front when I get it. I have almost exactly 10 inches of space for the graphics card with this configuaration. There is no way I can get the 670FTW into the case like this so I will have to wait until I am able to get the shorter PCB 670 so I can put a water block on it and have plenty of room for the rad and tube res. I also installed black plexi cover over the PSU to hide the cable clutter.

To mount the rad in the roof I had to cut an opening to exhaust the air. I depated on how to do this for a while and finally came to the conclusion to cut out a semi circle and used some of the mesh from the side panel as a grill. It looks okay but I am not 100% happy with it.

The fans that are attached to the rad are the Scythe Slipstream slim fans. They are very quite but do not perform very well. With a prime 95 run I did last night the temps where in the high 50's and never went above 60. The front of the case I modified to accept two 120mm fans wich gives me the option to add another 240 rad.

The specs for this build are as follows:

Case- In Win Dragon Slayer mATX case

CPU-i5-3570K

Motherboard- Asus Maximus IV GENE Z/GEN 3

GPU- EVGA GTX 460

Memory- Mushkin 8GB (2x4GB DDR3 PC3-16000 9-11-9-27 Ridgeback

PSU- Corsair AX-650

SSD-Corsair Force 3 90 GB

HDD- Seagate Barracuda 360 GB 7200rpm

Cooling- XSPC RayStorm, XSPC EX240 radiator, Bitspower Water Tank Z -Multi Option 150 Reservoir, Swiftech MCP35B Pump.

Fans- 2 Scythe Slipstream Slim fans & 2 Enermax T.B. Silence

Future plans include adding another 240 radiator, adding a EVGA GTX 670 SC with a RayStorm 670 water block, Bitfenix Alchemy White LED, Mayhems Pastel Grape Red coolant and PrimoFlex Pro LRT Black Tubing -3/8in. ID X 1/2in. OD.

Last edited: