Blade Runner

New member

Another case of a little job turning into a big one.........

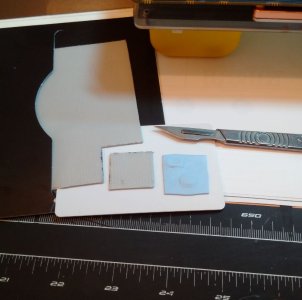

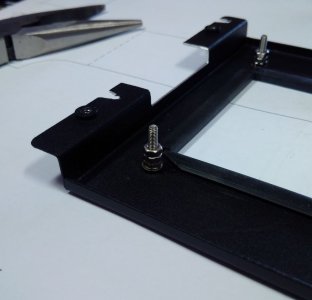

When I tested the monitor I noticed that the touch screen was not working, lots of searching and head scratching later I realised that it was not a driver problem but because I had squashed the screen too much around the edge where I had tightened it against the rubber edge trim.

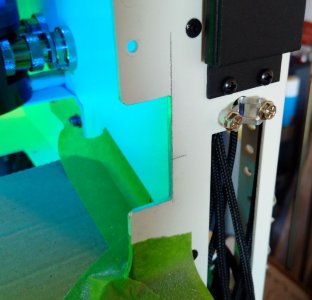

It was easy to sort out I put 3 nuts on each screw and tightened against them which has left the screen about 1mm clear of the rubber trim all round and working as it should.

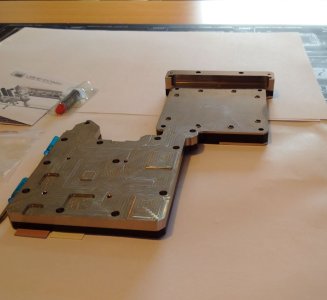

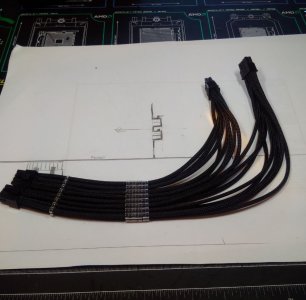

I thought the cut out on the chassis would just need to match the one on the FlexBay cover but after cutting it out and finishing it smooth it turned out that I had measured from the wrong side of the frame and I needed more cut out.

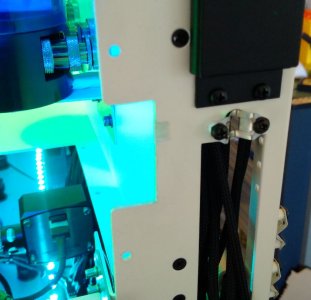

The final result can be seen below, with all the stopping and starting and re-doing of stuff it has took the best part of 5 hours, it just does not look like it!

I had always planned on covering the back of the monitor with a spare flex bay cover, I am just a bit undecided on which type. I like the vented type as I think it blends with the fan grills above better but the solid type does hide the monitor fully.

I may end up putting a cover plate behind the vented cover so I have the look of the vented cover with the covering up of the solid one.

When I tested the monitor I noticed that the touch screen was not working, lots of searching and head scratching later I realised that it was not a driver problem but because I had squashed the screen too much around the edge where I had tightened it against the rubber edge trim.

It was easy to sort out I put 3 nuts on each screw and tightened against them which has left the screen about 1mm clear of the rubber trim all round and working as it should.

I thought the cut out on the chassis would just need to match the one on the FlexBay cover but after cutting it out and finishing it smooth it turned out that I had measured from the wrong side of the frame and I needed more cut out.

The final result can be seen below, with all the stopping and starting and re-doing of stuff it has took the best part of 5 hours, it just does not look like it!

I had always planned on covering the back of the monitor with a spare flex bay cover, I am just a bit undecided on which type. I like the vented type as I think it blends with the fan grills above better but the solid type does hide the monitor fully.

I may end up putting a cover plate behind the vented cover so I have the look of the vented cover with the covering up of the solid one.

Attachments

-

Monitor_20.JPG86.6 KB · Views: 80

Monitor_20.JPG86.6 KB · Views: 80 -

Monitor_19.jpg81.8 KB · Views: 78

Monitor_19.jpg81.8 KB · Views: 78 -

Monitor_18.jpg90.9 KB · Views: 75

Monitor_18.jpg90.9 KB · Views: 75 -

Monitor_17.jpg91.1 KB · Views: 73

Monitor_17.jpg91.1 KB · Views: 73 -

Monitor_16.JPG94.6 KB · Views: 80

Monitor_16.JPG94.6 KB · Views: 80 -

Monitor_15.JPG73.7 KB · Views: 82

Monitor_15.JPG73.7 KB · Views: 82 -

Monitor_14.JPG56.5 KB · Views: 76

Monitor_14.JPG56.5 KB · Views: 76 -

Monitor_13.JPG78.5 KB · Views: 77

Monitor_13.JPG78.5 KB · Views: 77 -

Monitor_21.JPG50.2 KB · Views: 76

Monitor_21.JPG50.2 KB · Views: 76