I just sleeved my first PSU. I figured I'd share with you guys what I learned as I went.

1. It is a pain in the ass and it takes forever =)

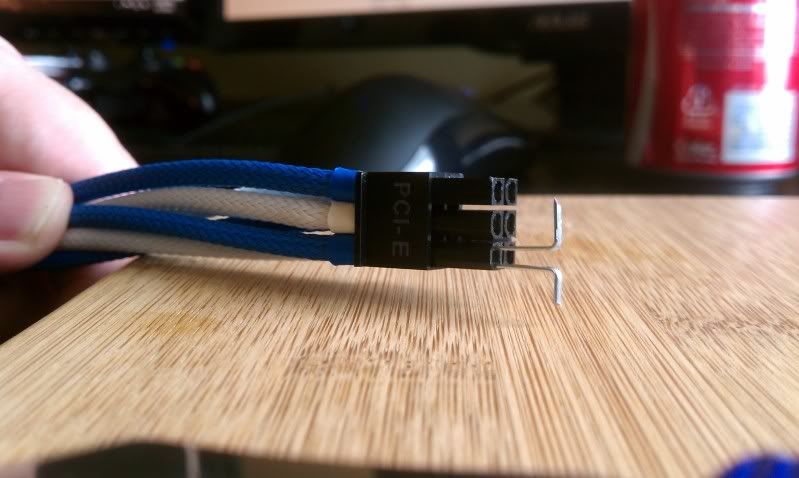

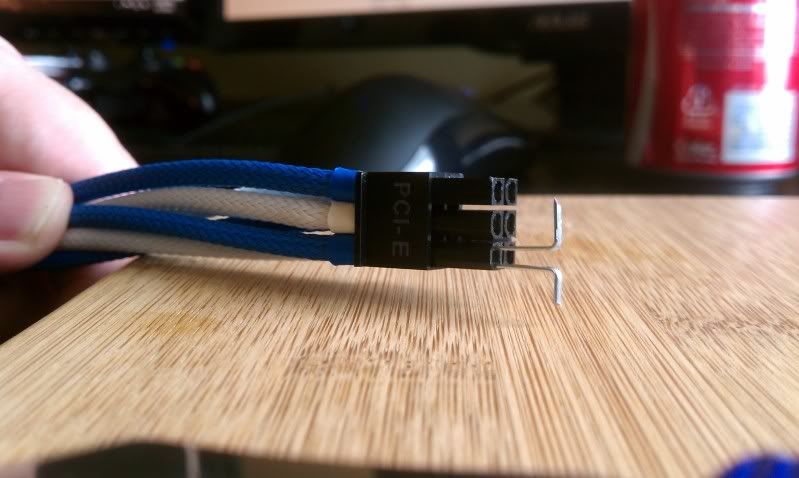

2. Don't waste money on a "pin removal tool" like this one for the 24 pin style connectors. It worked on some but on others I spent way to much time fiddling with it trying to get the pins out.

INSTEAD: just go to the store and spend a couple dollars on some heavy duty staples. Get the ones with the straight edge tip. You just cut one in half and you are good to go. These work perfect every time and if you bend one it's no big deal you just grab another staple from the box. the job got a ton easier after making the switch to staples.

3. 3/4' electrical tape is too wide to wrap the wires. You can do it but the wires look fat and the sleeving doesn't look as good. Cutting the tape in half you end up with perfect width tape but it is a tough task cutting a roll of electrical tape in half. Instead I found some 1/2" tape that works pretty well and you don't have to cut. Unfortunately, the only 1/2 tape I could find came in a multi color pack so it was kind of a waste buying a bunch of multi packs just for the white tape. I didn't mind though since it made my life quite a bit easier just being able to take tape off the roll.

4. Buy quite a lot more sleeving than you think you will need. I bought extra and still ran out from all the mistakes and redos I ended up doing. There were a bunch of wires I wish I could have redone.

It took me about a week to sleeve the whole thing 2 pretty much full days and then 4 days of after work sleeving . I imagine a lot of other people will say it can be done a lot quicker but I'm just letting you know how long it took me my first time. In the end it feels worth it though

Hopefully this will help some other newbie.

1. It is a pain in the ass and it takes forever =)

2. Don't waste money on a "pin removal tool" like this one for the 24 pin style connectors. It worked on some but on others I spent way to much time fiddling with it trying to get the pins out.

INSTEAD: just go to the store and spend a couple dollars on some heavy duty staples. Get the ones with the straight edge tip. You just cut one in half and you are good to go. These work perfect every time and if you bend one it's no big deal you just grab another staple from the box. the job got a ton easier after making the switch to staples.

3. 3/4' electrical tape is too wide to wrap the wires. You can do it but the wires look fat and the sleeving doesn't look as good. Cutting the tape in half you end up with perfect width tape but it is a tough task cutting a roll of electrical tape in half. Instead I found some 1/2" tape that works pretty well and you don't have to cut. Unfortunately, the only 1/2 tape I could find came in a multi color pack so it was kind of a waste buying a bunch of multi packs just for the white tape. I didn't mind though since it made my life quite a bit easier just being able to take tape off the roll.

4. Buy quite a lot more sleeving than you think you will need. I bought extra and still ran out from all the mistakes and redos I ended up doing. There were a bunch of wires I wish I could have redone.

It took me about a week to sleeve the whole thing 2 pretty much full days and then 4 days of after work sleeving . I imagine a lot of other people will say it can be done a lot quicker but I'm just letting you know how long it took me my first time. In the end it feels worth it though

Hopefully this will help some other newbie.