Tap washers..

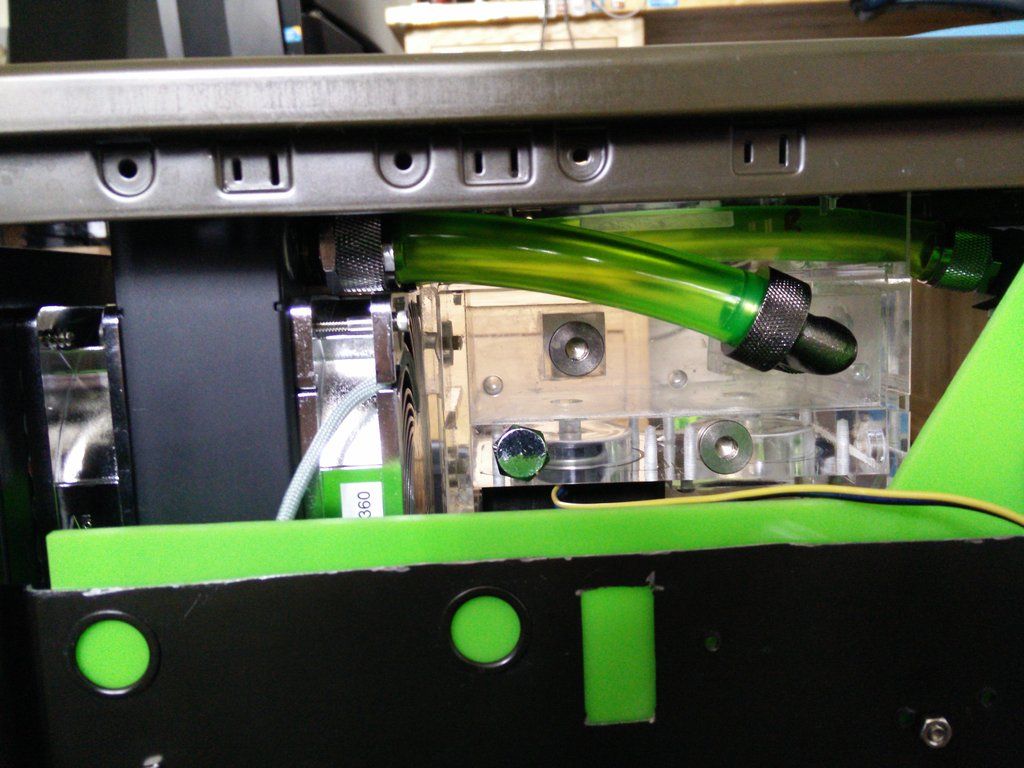

Last night due to the TV being crap I decided I was going to start the build. I decided I wanted to fit the radiator and the res, which meant that I needed to do the hoses for the rad as the rad is not accessible once the res goes in. This meant it was going to be tricky...

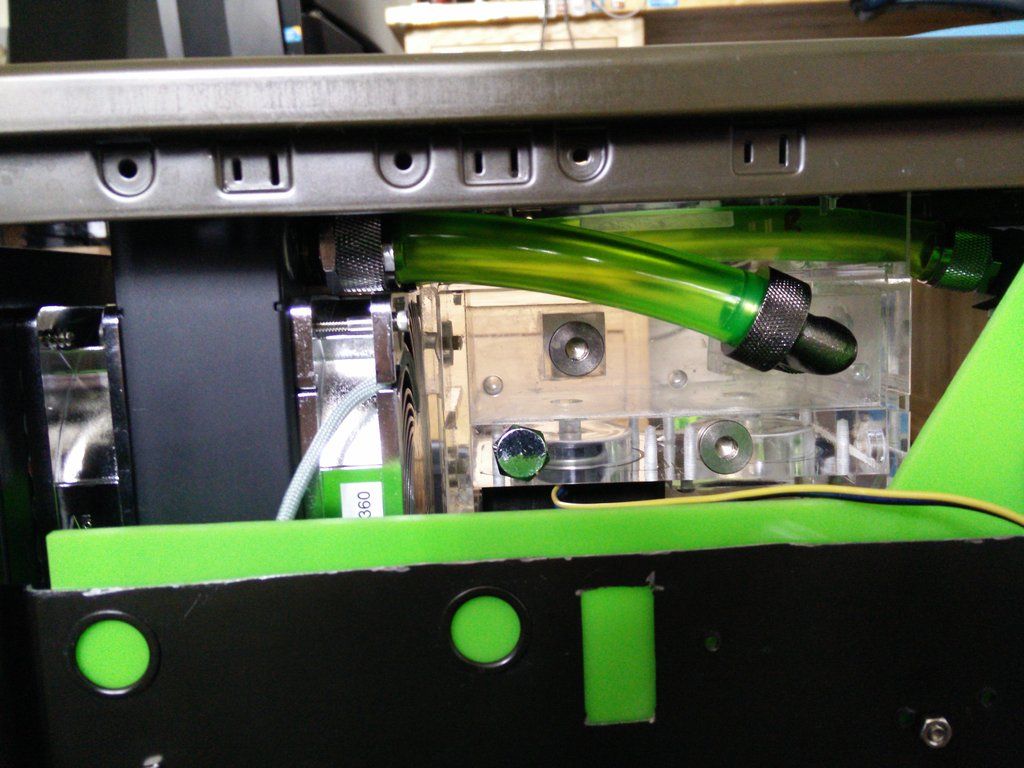

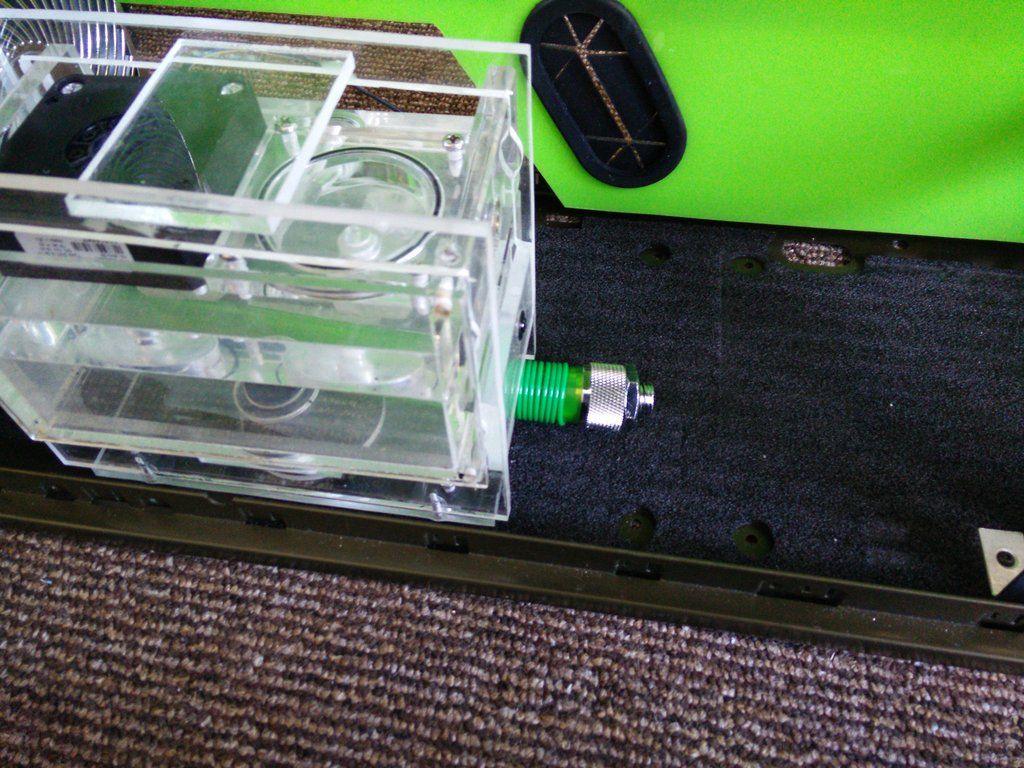

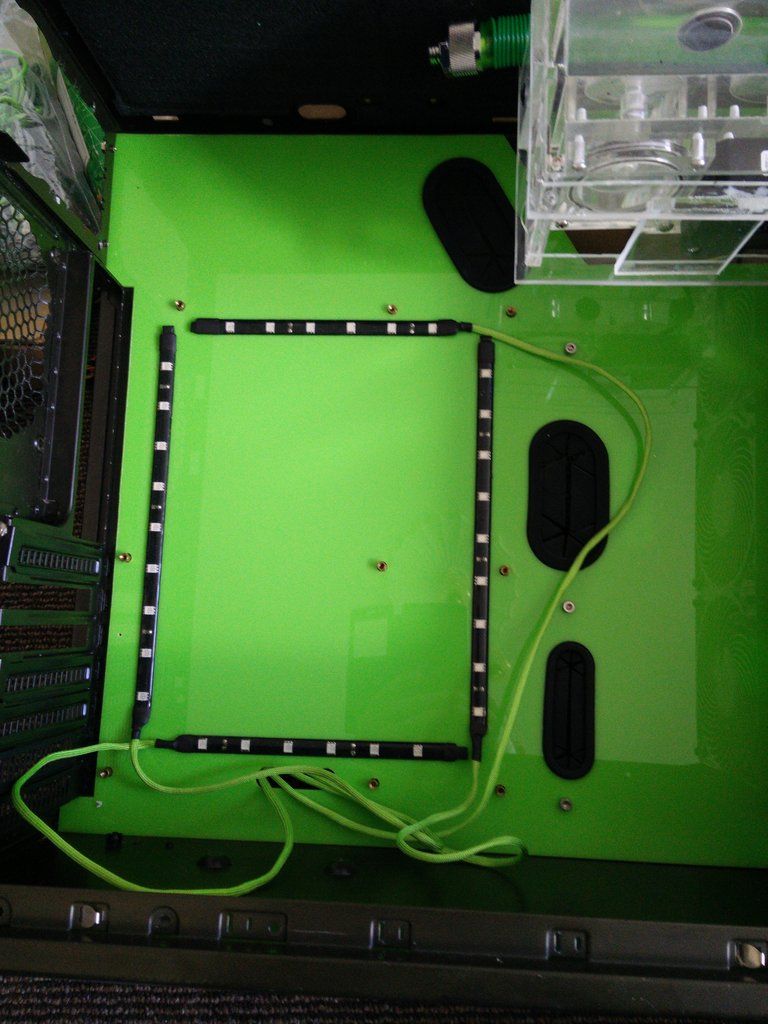

So I fitted the rad and fitted a small curved hose (so I could cut it once the res was in) and a pre straightened hose that I had heated with the heat gun earlier. So I fitted the rad in and went to mount up the res bay. Disaster ! Like a complete noob when I measured it all up and pre fitted it I did so without the fittings. And because the tolerances were so unbelievably tight the res bay and indeed res would not fit with the fittings in the rad. I panicked, reasoning "if this doesn't fit then absolutely nothing else will because it was all designed around this !". Thankfully in the end it wasn't so dramatic.

Around exactly a month ago before I started the build I was digging around in my spares bins for stuff to use on the build. I came across a padded envelope full of these.

I remember saying to myself "Eee, these may come in handy you never know !". What I was thinking god only knows, but they completely saved my life. I had to stack two together to drop the res bay by 6mm. Only dropping it (and not moving it horizontally) meant that the shroud panel I took two days to make would still fit, and because I had made it to go all the way to the roof of the case I had some breathing room left in. PHEW.

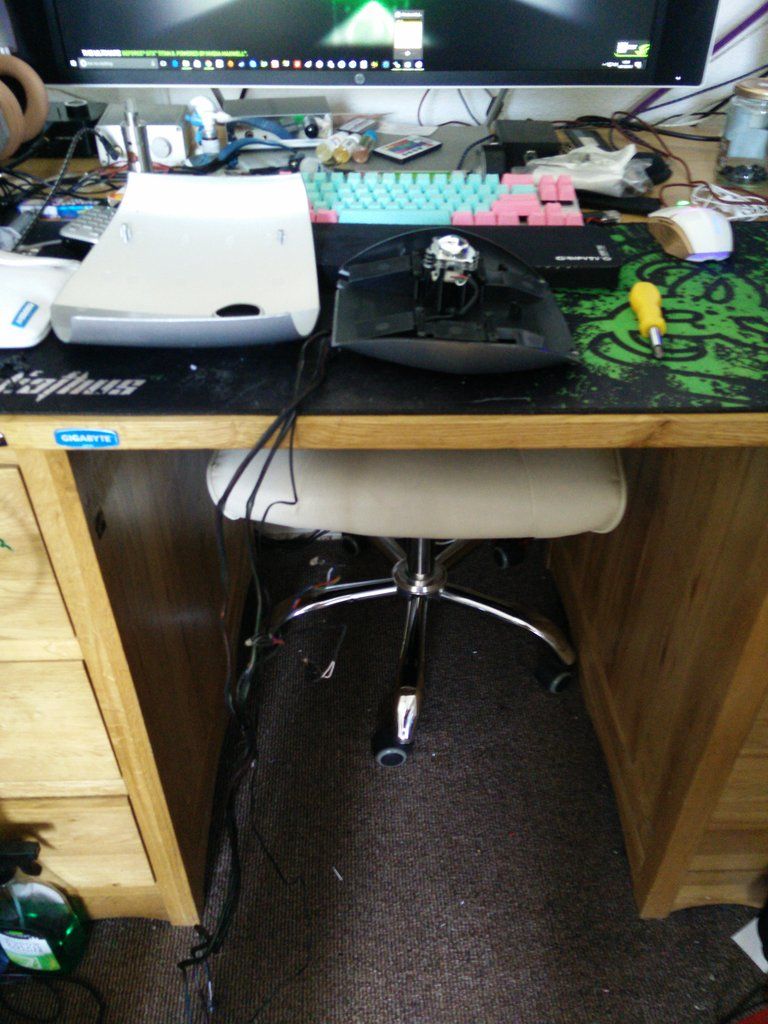

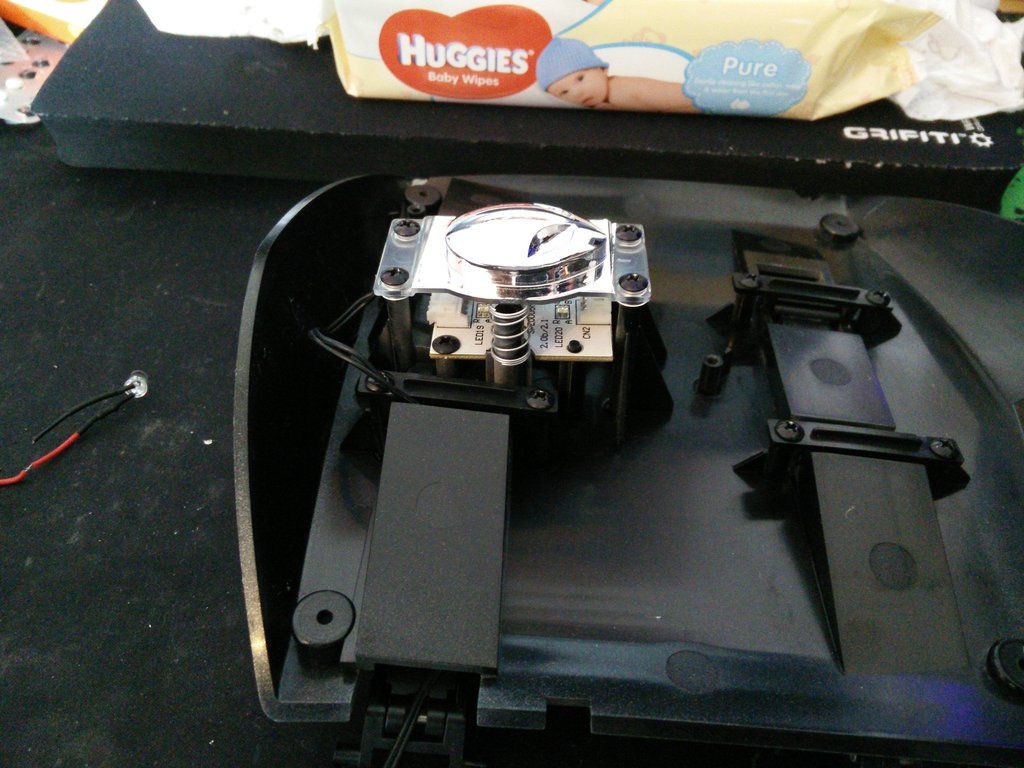

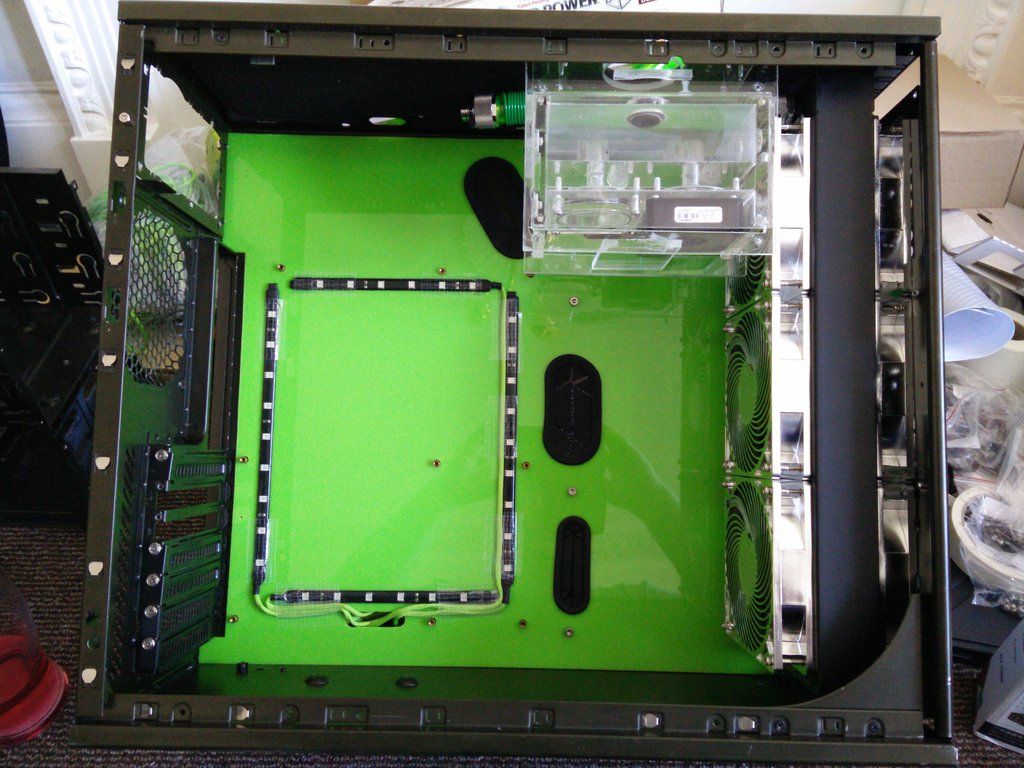

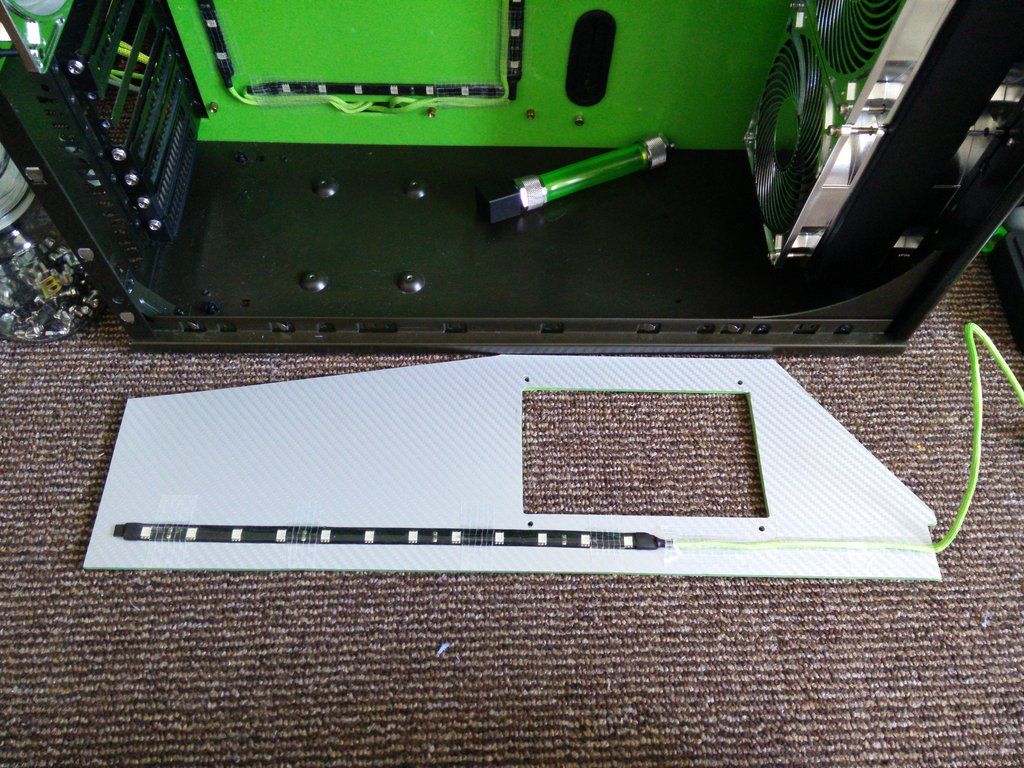

So I set to work. Here is how it looks right now, ignore the Dr Drop I am paranoid with it being my first ever water build so I am pressure testing at every stage.

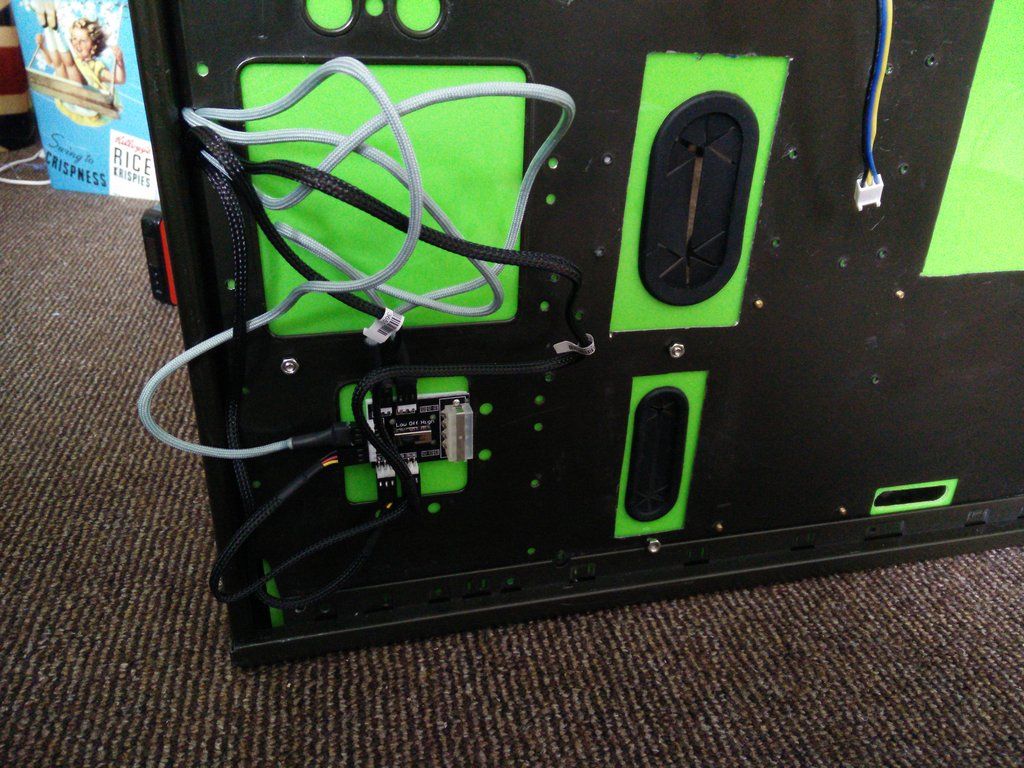

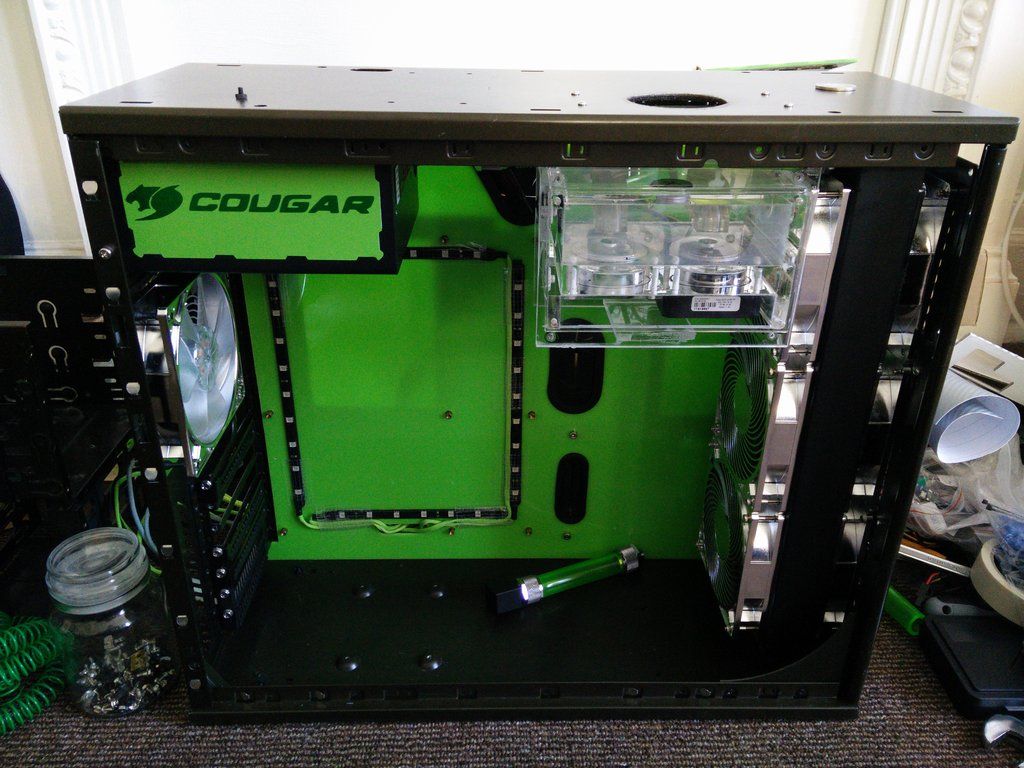

And here is how it looks from the back.

Those were the two hardest, and the ones I needed to do at the beginning. Typical me

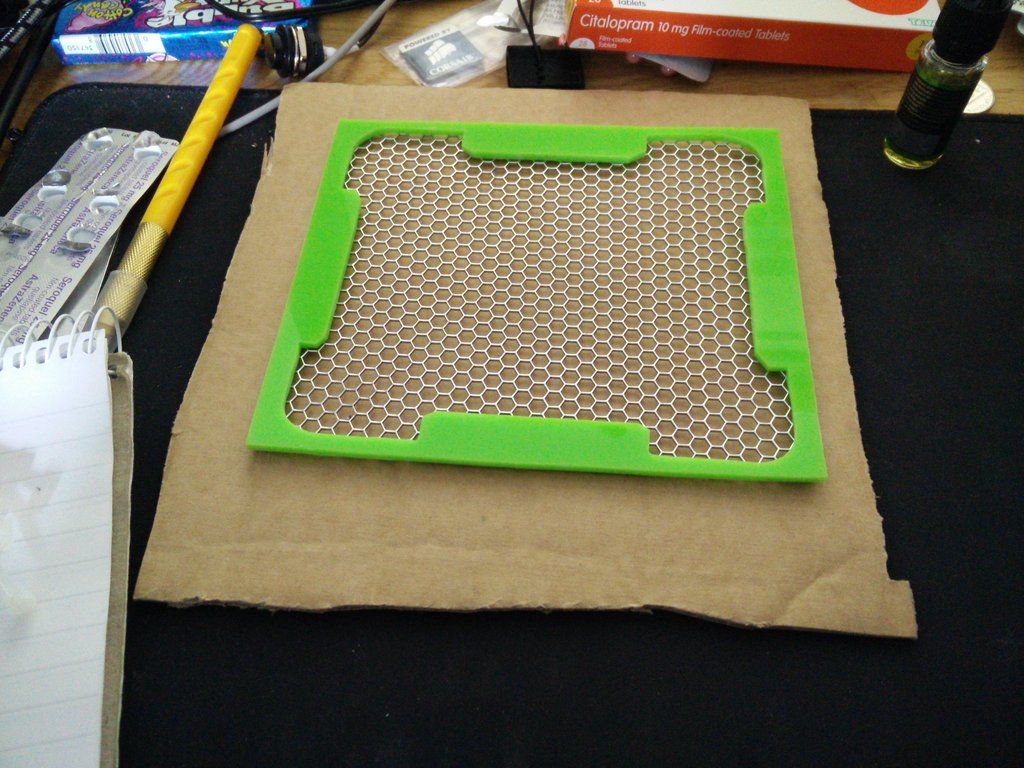

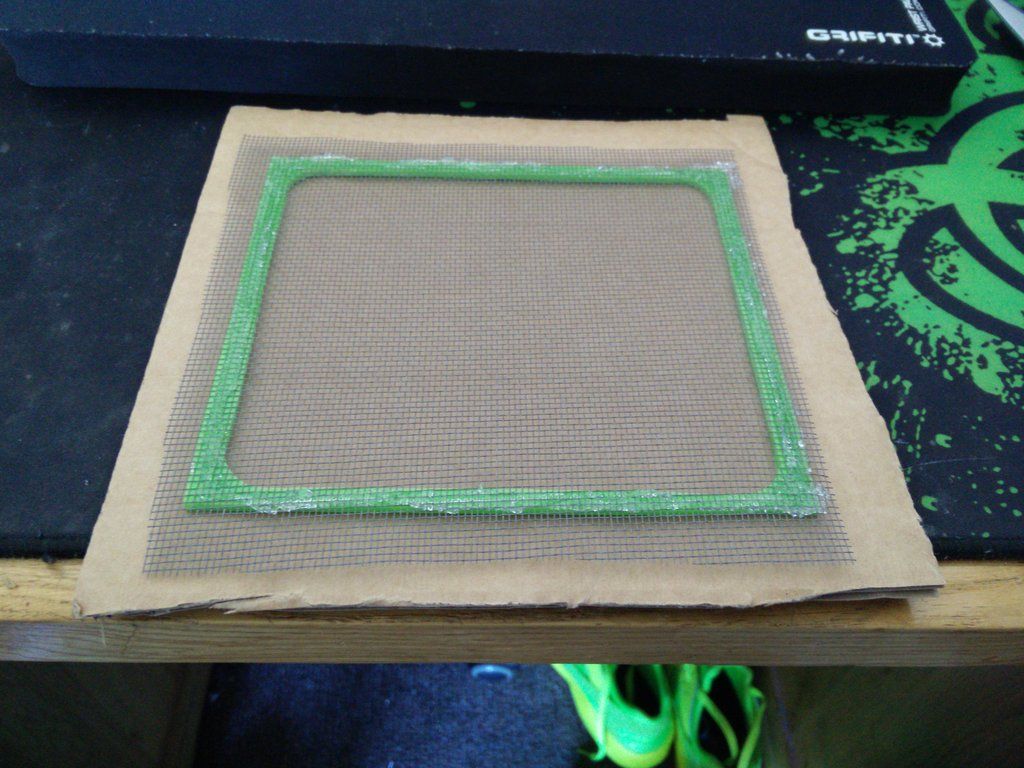

In other news I was digging around on the bay last night looking for something to use as feet. Long story short, I sprained my wrist on the very first day of the build cutting a hole in the res bay and ever since I have been in agony. I've been wearing a wrist strap for the most part, but absolutely cannot wear that when I am working. So I won't be cutting any feet. I wanted something billet, but billet = funds. So I found these.

They are billet. They are 1" hood spacers that go between your car's bonnet and the plate to offer cooling to the turbo etc. They come with everything you see in the pic, though I got mine in green.

There isn't a pic of green ones showing exactly what you get, hence the purple.

£8, and even include the M6 bolts (will need cutting down).

Mine's wrecked