imersa

New member

Hi OC3D, since starting this little filler project way back in October there has been a lot going on at Parvum, lots of other custom builds and the release of our two ITX cases. With a little help from someone most of you will know we now have a little more time to dedicate to this project and port the log over to you guys on OC3D. So just to get you up to speed I will condense the first couple of updates into one post. Some elements will be cut out just so it reads better in retrospect as the project has evolved somewhat since it started.

This build is possible with the support of Intel, Hyper X, nVidia, ASUS and EKWB.

The build will explore many new materials and techniques, taking inspiration from Architecture and Industry. I tend to gather a series of images and physical items before I start anything, I thought I would share them.

Main Components

Case - Custom Steel Parvum X1.0

CPU - Intel i5 4670k

Motherboard - Asus Maximus VII Impact

Memory - Hyper X Fury

GPU - Asus GTX 750Ti

SSD - Hyper X 3K

PSU - Silverstone Strider SFX450

Miscellaneous

MDPC-X Sleeving

GPU Cooler - Alpenfoehn Peter

First up some of the base panels for the case. Laser cut entirely from 5mm thick mild steel. We then left the panels to weather a little. The rebated holes and chamfered edge have been done by hand. We then sanded down some parts of the panel and left the raw look here. We sealed the panels with a lacquer to prevent further weathering and darken down the over all look.

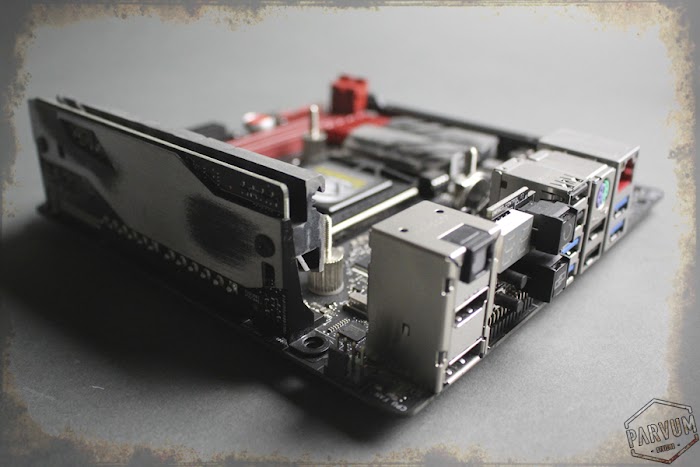

ASUS ROG sent the board. Thanks guys. A shot of the thing (You've all seen the Impact by now) and a photo with bits removed.

What could we do with those?

Next the mighty GPU cooler from Alpenfoehn arrived at the Parvum HQ.

I wanted to keep away from the very bright chrome so we had to step into some unfamiliar territory here. I'm usually not a fan of making things look aged or old but really wanted a rough and organic feel here. I suppose with an architectural background; the desire to mix rustic and aged with clean and sophisticated was always to our taste.

We first sanded the nickel plating with a fine grit and dunked into a a bronzing solution to eat away at the cooler. Not wanting any harm to come to our friend Peter II we let another cooler with a far less human name take the plunge first.

With a significant bulk of the parts standing by it was time for a test fit!

Even Peter II slotted nicely into place.

Now we are all on the same page updates shall commence as events unfold. Thanks for dropping by the thread, talk to you soon ^_^