I hear ya buddy, I picked up a pair of 60mm Noctua fans too, for the PSUs. Even though I really should have double checked what fan is in the V2s PSU before I did that, DOH! I know I can replace the 60mm in the Meanwell PSU I bought for the E5+, but I have no clue what PSU is in the V2 yet. I'm trying NOT to take that apart too much, since it's the only working printer I have right now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OC3D 3D Printing enthusiasts

- Thread starter Warchild

- Start date

Printed these awhile back for my side-by-side:

The actual oem dome lights from Polaris were $70 each and not even LED so there was no way I was going to pay that much. They fit exactly where the oem lights go and are much brighter and at a fraction of the cost.

I was going to design something myself, but it already existed on thingiverse:

https://www.thingiverse.com/thing:3839203#Summary

The actual oem dome lights from Polaris were $70 each and not even LED so there was no way I was going to pay that much. They fit exactly where the oem lights go and are much brighter and at a fraction of the cost.

I was going to design something myself, but it already existed on thingiverse:

https://www.thingiverse.com/thing:3839203#Summary

NeverBackDown

AMD Enthusiast

Side by sides are so much fun! I don't own one but driven them before and they are blast. Terrible turning radius though

It's crazy how much they charge for accessories though. Makes you think that's the only place they make money looking at the prices! Better option to rent sometimes

It's crazy how much they charge for accessories though. Makes you think that's the only place they make money looking at the prices! Better option to rent sometimes

Side by sides are so much fun! I don't own one but driven them before and they are blast. Terrible turning radius though

It's crazy how much they charge for accessories though. Makes you think that's the only place they make money looking at the prices! Better option to rent sometimes

What is a side-by-side?

What is a side-by-side?

An off-road vehicle.

https://ranger.polaris.com/en-us/

They are fun, but definitely money pits. I've been looking to upgrade, but the one I want right now has a sticker price of $34k.

So I decided to install the SKR 1.4 turbo in my Ender 5 Plus, and I think I goofed BIG time, because I'm seeing weird things, and I am too inexperienced with electrical crap to figure this out. So get this: if I heat my bed BY ITSELF, bed and bed alone, the printer pulls 585W out of the wall, continuously. Out of a 450W Meanwell PSU. So before I burn my house down, any idea where I went wrong on the wiring?

NeverBackDown

AMD Enthusiast

What is a side-by-side?

An off-road vehicle.

https://ranger.polaris.com/en-us/

They are fun, but definitely money pits. I've been looking to upgrade, but the one I want right now has a sticker price of $34k.

As hmmblah stated an off-road vehicle

Basically purpose built for off-road only. Some people don't want to modify their actual trucks for off road, so they tow these on a trailer and use them for their off road adventures instead. Quite popular in the US.

They aren't really street legal I should add, you can make them so(I have driven street legal versions on the road before) but it's difficult and not everywhere allows it.

As hmmblah stated an off-road vehicle

Basically purpose built for off-road only. Some people don't want to modify their actual trucks for off road, so they tow these on a trailer and use them for their off road adventures instead. Quite popular in the US.

They aren't really street legal I should add, you can make them so(I have driven street legal versions on the road before) but it's difficult and not everywhere allows it.

But how did it adopt the name side by side? what is the link with that and offroad.

I have always branded all such vehicles as "off road" or "4x4". First I had heard of side by side before. They do look super fun though! but those prices for a little fun on the "side" makes my hobbies look like pennies to maintain.

But how did it adopt the name side by side? what is the link with that and offroad.

I have always branded all such vehicles as "off road" or "4x4". First I had heard of side by side before. They do look super fun though! but those prices for a little fun on the "side" makes my hobbies look like pennies to maintain.

The passenger sits next to you instead of behind you like on a 4-wheeler (quad).

The passenger sits next to you instead of behind you like on a 4-wheeler (quad).

aha, makes sense then

Look barrels of fun, but a money pit is an understatement i guess.

Toying with the idea of a large Cable cover that extends to cover the 24pin plug and Sata connectors.

Maybe one day I will finally finish my 1000D build, right now the cable management looks like a train wreck met a destruction derby that was hosted at a Ming Vase convention.

Thing is my printer doesnt print that big so gotta split it somehow. But I plan to magnetise it like I did with my HOTAS mount so I dont need to cut the 1000D case at all, and I can remove it anytime I want.

Maybe one day I will finally finish my 1000D build, right now the cable management looks like a train wreck met a destruction derby that was hosted at a Ming Vase convention.

Thing is my printer doesnt print that big so gotta split it somehow. But I plan to magnetise it like I did with my HOTAS mount so I dont need to cut the 1000D case at all, and I can remove it anytime I want.

Nice work sir! If I can ever get both of my printers working well, I really need to put myself "back to school" and learn now to do my own modelling. The brand new Ender 3 V2 I bought is a total lemon, so I'm fighting with that while trying to mod my busted old Ender 5 Plus at the same time. It's been a tough slog, but I'm making *some* progress.

This was a historic weekend, as my poor old Ender 5 Plus finally got some much needed love. After upgrading to the SKR 1.4 Turbo board with 2209 drivers, next target was the PSU. When I bought this 2 years ago, it came with a *terrible* PSU, so that was replaced with a 450W Meanwell immediately. Since I upgraded the board however, I noticed something bad when I hooked the printer up to a UPS: I could pull a STEADY 575W from the wall JUST by heating the bed. Out of a 450W PSU, not good.

So I listened to my inner Scotty from Star Trek: "we need more power Captain!!!". Yes, yes we do, hence a new 600W Meanwell unit:

Now this thicc boi isn't fitting in the stock PSU compartment, so arrangements had to be made. I basically replicated what Kris from Kersey Fabrications YT channel did, and drilled some extra holes in the back of the case to route the wires, and mounted the PSU externally on the rear with some 3d printed brackets. Would have much preferred metal mounts, but this will do:

Mod #2 in this round was the Micro Swiss all metal hot end. Bought this thing ages ago, but due to the "great basement flood of 2019" I didn't get around to installing it until now, about bloody time:

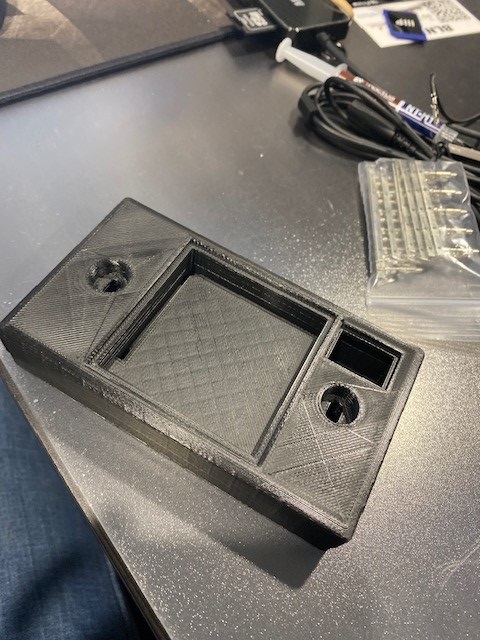

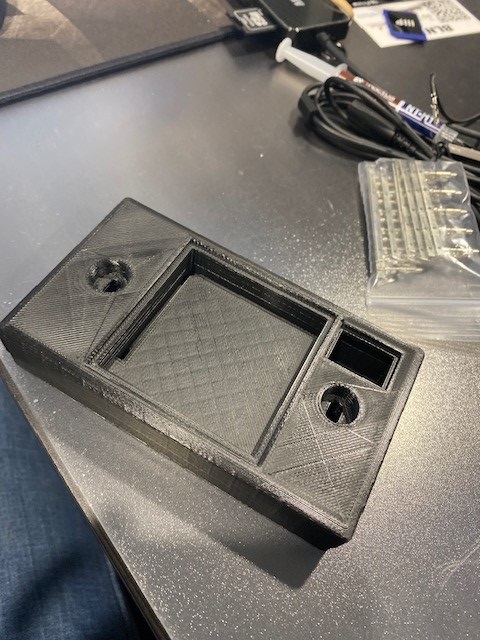

Mod #3 required a printed part from my sketchy E3 V2, thankfully it managed it with no issues:

This was for the Bondtech BMG extruder, since Creality extruders are a blight upon humankind. I needed a new plate to align the thick BMG with the stock filament sensor:

Mounted up:

Now that he's all modded up, I gave him a name. Some old nerds might remember the movie Short Circuit, from way back, family movie about a robot named Johnny-5:

I've also been doing lots of toying with Marlin, and all the newer levelling features, mesh creation, etc. Big learning curve there, but I managed to get auto-alignment working on my Z-screws via the G34 command, and via the LCD. Very cool stuff. I split my Z-motors off onto different steppers so I can align them with each other in firmware, down to 0.02mm accuracy:

This was a historic weekend, as my poor old Ender 5 Plus finally got some much needed love. After upgrading to the SKR 1.4 Turbo board with 2209 drivers, next target was the PSU. When I bought this 2 years ago, it came with a *terrible* PSU, so that was replaced with a 450W Meanwell immediately. Since I upgraded the board however, I noticed something bad when I hooked the printer up to a UPS: I could pull a STEADY 575W from the wall JUST by heating the bed. Out of a 450W PSU, not good.

So I listened to my inner Scotty from Star Trek: "we need more power Captain!!!". Yes, yes we do, hence a new 600W Meanwell unit:

Now this thicc boi isn't fitting in the stock PSU compartment, so arrangements had to be made. I basically replicated what Kris from Kersey Fabrications YT channel did, and drilled some extra holes in the back of the case to route the wires, and mounted the PSU externally on the rear with some 3d printed brackets. Would have much preferred metal mounts, but this will do:

Mod #2 in this round was the Micro Swiss all metal hot end. Bought this thing ages ago, but due to the "great basement flood of 2019" I didn't get around to installing it until now, about bloody time:

Mod #3 required a printed part from my sketchy E3 V2, thankfully it managed it with no issues:

This was for the Bondtech BMG extruder, since Creality extruders are a blight upon humankind. I needed a new plate to align the thick BMG with the stock filament sensor:

Mounted up:

Now that he's all modded up, I gave him a name. Some old nerds might remember the movie Short Circuit, from way back, family movie about a robot named Johnny-5:

I've also been doing lots of toying with Marlin, and all the newer levelling features, mesh creation, etc. Big learning curve there, but I managed to get auto-alignment working on my Z-screws via the G34 command, and via the LCD. Very cool stuff. I split my Z-motors off onto different steppers so I can align them with each other in firmware, down to 0.02mm accuracy:

It's official, after nearly 2 years, Bartie-5 is now fully online and print capable! Woohoo! To top him off properly, I think I just impulse bought the best mod I never knew I needed until I installed it, and it came from Creality. I picked up their magnetic spring steel PEI bed surface kit, along with some replacement z-screws, metal brushes, new flexible z-screw couplings, and a Creality silent fan for the hot end:

Two piece couplings installed, no idea if this will be of any benefit, but they make sense and were cheap:

Magnetic sheet install commences (yes it was a mess, and there were air bubbles). I ended up puncturing the bigger ones with a knife tip to get the air out.

After much foul language, Bartie-5 got shiny:

First layer going down a bit thin, needed to back the nozzle off a bit:

Adjustments were made:

Dots complete, Z-offset pretty much dialed in and the bed is levelled, I think!

After releasing those dots from the print surface, I am in LOVE with this PEI spring steel sheet!!!! Where has this been all my life?!!?!?! Best upgrade EVER!!!!

Two piece couplings installed, no idea if this will be of any benefit, but they make sense and were cheap:

Magnetic sheet install commences (yes it was a mess, and there were air bubbles). I ended up puncturing the bigger ones with a knife tip to get the air out.

After much foul language, Bartie-5 got shiny:

First layer going down a bit thin, needed to back the nozzle off a bit:

Adjustments were made:

Dots complete, Z-offset pretty much dialed in and the bed is levelled, I think!

After releasing those dots from the print surface, I am in LOVE with this PEI spring steel sheet!!!! Where has this been all my life?!!?!?! Best upgrade EVER!!!!

WYP

News Guru

That's pretty cool. I don't think I will a try though. That project sounds like a time sync.

WYP

News Guru

that's a lot of fizzy drinks you'd have to get through

Interesting in-home recycling though.

WYP

News Guru

By the time you have enough to make anything big you'd have diabetes

Yeah. I don't think anyone goes through enough bottles of anything to make this worthwhile. Anyone who did has a fizzy drink problem, unless they are a bottled water fanatic.

Last edited: