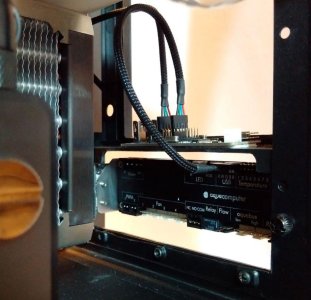

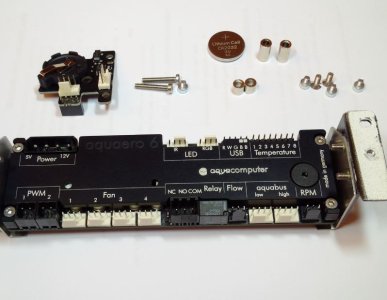

If it still looks wrong, I will just take off the display and use it without, with the panel going over it. I have not used the touch screen on my Aqueros since I installed the Aquasuite so its not really essential, a sort of Aquero 6Lt?

I wish the 6LT was a legit thing. I really hate the idea of having a screen on it and mounting it somewhere external. 5LT's were excellent and at least made it somewhat affordable to go with an Aquaero, I do want to use them again for Lightning. How did you find they got on with PCB splitters and iPPC's any control issues at all? I'm still sort of tempted by dual 5LT's and voltage control like my current setup.

JR