You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Devil's own V. 2.0

- Thread starter Devildog83

- Start date

RickPlaysWarr

New member

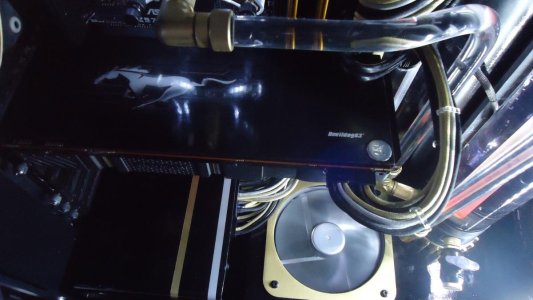

Here is a test fit of the pump/res - It fits!!!

Looking Very awesome. How is the pump/res combo held in? Just fitted into the plexi bottom shield?

Love the plexi work you do. Do you have a pointer to some instructions or a tutorial?

--Rick__

Devildog83

New member

I cut it with a jigsaw and then smooth the edges with a palm sander, dremel or a sanding bit on a drill, whichever is needed.

For bending it's easy, there are many video's on youtube but I just use a heat-gun.

For cutting make sure you have the piece very sturdy because too much vibration will make it heat u and then it fuses back together so hold it well and cut smooth and not too fast or too slow. Use a very narrow jig saw blade, especially for round cuts.

For bending, never hold the heat-gun in the same place too long, move back and forth and be careful too heat it up just enough to bend it. Then hold it in place until cool. It might spring back on some bends so holding it just past 90 degrees will help. You can always heat it up again to adjust but be very careful as if it is heated too much it will bubble and warp.

I use good plastics glue to glue plastic spacers of the correct length in the right places on the inside and then double sided 3M tape to hold them in place.

For painting if you want I sand the part with a palm sander and 220 grit paper before a primer coat, 2 or 3 color coats and 2 or 3 clear coats, the more the better.

Just ask if you need any other help. Main thing is to think everything through be patient and be careful because the stuff will crack easily.

I bolted it to the back through 2 layers of Plexi-glass.

For bending it's easy, there are many video's on youtube but I just use a heat-gun.

For cutting make sure you have the piece very sturdy because too much vibration will make it heat u and then it fuses back together so hold it well and cut smooth and not too fast or too slow. Use a very narrow jig saw blade, especially for round cuts.

For bending, never hold the heat-gun in the same place too long, move back and forth and be careful too heat it up just enough to bend it. Then hold it in place until cool. It might spring back on some bends so holding it just past 90 degrees will help. You can always heat it up again to adjust but be very careful as if it is heated too much it will bubble and warp.

I use good plastics glue to glue plastic spacers of the correct length in the right places on the inside and then double sided 3M tape to hold them in place.

For painting if you want I sand the part with a palm sander and 220 grit paper before a primer coat, 2 or 3 color coats and 2 or 3 clear coats, the more the better.

Just ask if you need any other help. Main thing is to think everything through be patient and be careful because the stuff will crack easily.

Looking Very awesome. How is the pump/res combo held in? Just fitted into the plexi bottom shield?

Love the plexi work you do. Do you have a pointer to some instructions or a tutorial?

--Rick__

I bolted it to the back through 2 layers of Plexi-glass.

Last edited by a moderator:

Devildog83

New member

Devildog83

New member

Thank you sir!!

Dicehunter

Resident Newb

That is a perfect looking rig

Devildog83

New member

Devildog83

New member

Devildog83

New member

voodoografix

New member

Looking sexy ( not you the rig )