why do the connections have double wires? (really confused about this)

I'm not an absolute PSU expert, so if anyone spots an error feel free to correct me.

Every PSU needs to do voltage control. This means that the PSU needs to check that its 12 V

line actually puts out 12 V, the 5 V delivers 5 V and so on. The important part is that those

voltages need to be supplied at the connector to the components, and not where the PSU

connects to its cables.

Now, there's a nice little equation linking resistance, current and voltage drop over an electrical

element:

Code:

U=R*I

U: voltage drop over element

R: element resistance

I: current through element

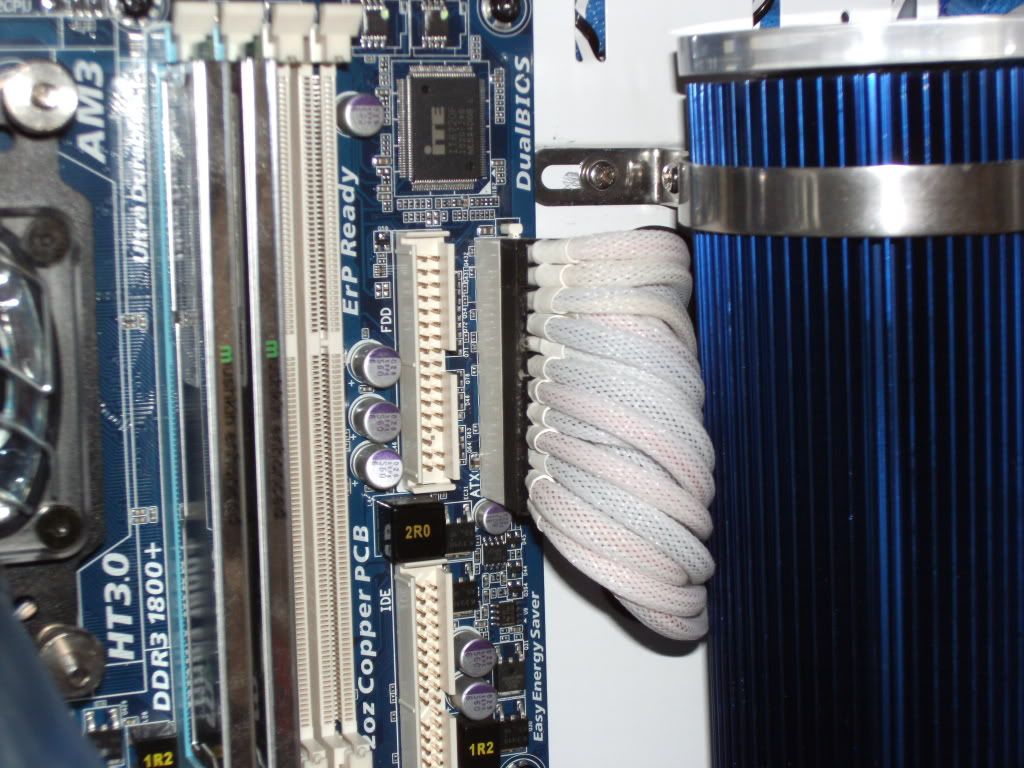

Every wire that goes from the PSU to each respective component (say, the 24 pin connector

on the M/B ) has a resistance and a current which flows through it (usually). That current can

of course change depending on how much load the system is under.

So the voltage drop between the PSU and the 24 pin connector on the mainboard will not always

be the same and will change with system load. Voltage regulation needs to take this into account.

In order to be able to do that, the PSU needs to measure the voltage at the M/B end of the

connection. In order to do that, you use a second wire which you connect to the M/B crimp

terminal on one end and to a voltage sensor input on the PSU side. That wire will have

almost

not current flowing through it, meaning that the voltage drop over that wire from the 24 pin back

to the PSU will be practically nothing (or, to use an engineer's favourite word: negligible

).

Example:

Let's assume you have an 18 AWG wire going from the PSU to the 24 pin, delivering a current

of 5 amperes. The voltage drop you will have from the PSU to the M/B in that wire will then

roughly be:

Code:

U=R*I=rho*L*I=0.00002096 ohm/mm * 500 mm * 5 A = 0.05 V = 50 mV

U = voltage drop over wire

rho: resistance per length of wire, 0.00639 ohm/foot

L: length of wire, 0.5 m in this example

I: current, 5 A here

Source for wire resistance value (I've metrified it for this calculation):

link.

In this example you would have a voltage drop of 50 mV between the PSU and the 24 pin

on the M/B, which is not insignificant.

The secondary wire has no current flowing through it (or almost none, not 100 % sure on that,

somebody who's an expert on PSU design might be able to say), which means that the voltage

drop over the secondary wire from the 24 pin back to the PSU will of course be:

And this allows you to accurately read the actual voltage at the 24 pin connector. Of course I

have not taken into account the actual resistance in the crimp connector and all that stuff, but

I hope this makes things a bit clearer.

This is also why I'm not sure if there might be problems when you connect the voltage sense

wire to the current carrying wire almost back at the PSU. The voltage you will read with the

sense wire will be incorrect in that case. Whether or not the error will be large enough to cause

any problems I'm not sure about.