Hi everyone

I recently decided to go down the custom water cooling route to challenge myself a bit. Long story short. I upgraded from a be quiet! Dark Rock Pro 3 to the following Alphacool NexXxoS Cool Answer 240 D5/UT - kit. I learned about all the basics that I had to know, watched lots of instructional videos and read tons of sites on the subject. I work in IT and have been building my own PC systems for the past 5 years, so I am no novice to PC hardware.

Here's a list of the Components in the water cooling kit:

1x Alphacool NexXxoS XP3 Light - Intel/AMD

1x Alphacool Repack - Single Laing D5 - Dual 5,25 Bay Station

1x Alphacool VPP655 - Single Edition

1x Alphacool NexXxoS UT60 Full Copper

3x Alphacool tubing AlphaTube HF 13/10 (3/8“ID) - clear

6x Alphacool HF 13/10 Anschraubtülle G1/4 - Deep Black

1x Alphacool NB-eLoop 1200rpm - Bionic Lüfter (120x120x25mm)

1x Alphacool CKC Cape Kelvin Catcher Clear 1000ml

1x ATX-bridging plug (24 Pin) - black

I have set everything up, bled the system for 48 hours making sure there are no leaks etc. However, now that I have my computer running, I ran AIDA64 and quickly discovered that my temps are through the roof. like, between 87°C and 98°C depending on the core.

I am running an Asus ROG Z170 Maximus VIII Hero Motherboard with an Intel Core i7 6700K Processor in a Corsair Obsidian 750D. I tested out different clocks from 4.0GHz to 4.6GHz which has been running stable for the past 4-5 months. The i7 does NOT throttle or crash, the temps are simply really high.

I just can't figure out why the temps would be so high. I reseated the CPU cooler, applied a different and new type of thermal paste (because my other tube was 5 years old, who knows), set the fans to max settings, air is coming through the radiator.

Is my pump broken? Since this was the first time doing a water cooling loop, I turned the PSU on and off to allow the water to go through all of the components in the loop. I got a little ambitious and it took me about 4 seconds to realize what a dry pump sounds like *eeeeek*. Should I invest in a flow meter? but when I turn up the pump speed to max, air disturbance gets pumped through the loop which I can visually see moving around at a seemingly fast speed. Also the pump has no rattling noise or anything that I wouldn't think is normal operating sounds. Is the pump ruined from 4 seconds of dry running?

Is my motherboard broken? Is it possible that my motherboard is broken? ESD? I wouldn't think so since my system is stable, simply running hot.

Is my CPU broken? Could I have fried my CPU? When I still had my be quiet Dark Rock Pro 3, I used Asus' Dual Intelligent Processor 5 to OC my CPU (I know I know...) but it worked and settled at 4.7-4.8, but I set it to 4.6 just to be 100% stable at all times. Now, with my custom loop, when I run Dual Intelligent Processor 5 to OC my CPU, it cancels on the first run through and doesn't actually test to see if the CPU is able to go to any higher clocks than the mildest overclock which is 7%. The nature of the program is that it simply reboots, and goes to the next step in the OC process which is determining the fan settings, so I don't get an error message or failed etc.

Are my Alphacool NB-eLoop 1200rpm fans ? I feel air coming through the rads, but I don't know if it's enough. Even at full speed, the temps go up to 90°C.

So guys, hope you have your Sherlock hats and pipes ready, as I appreciate every single one of you who reads through this wall of text and tries to help me solve this.

Cheers,

baN

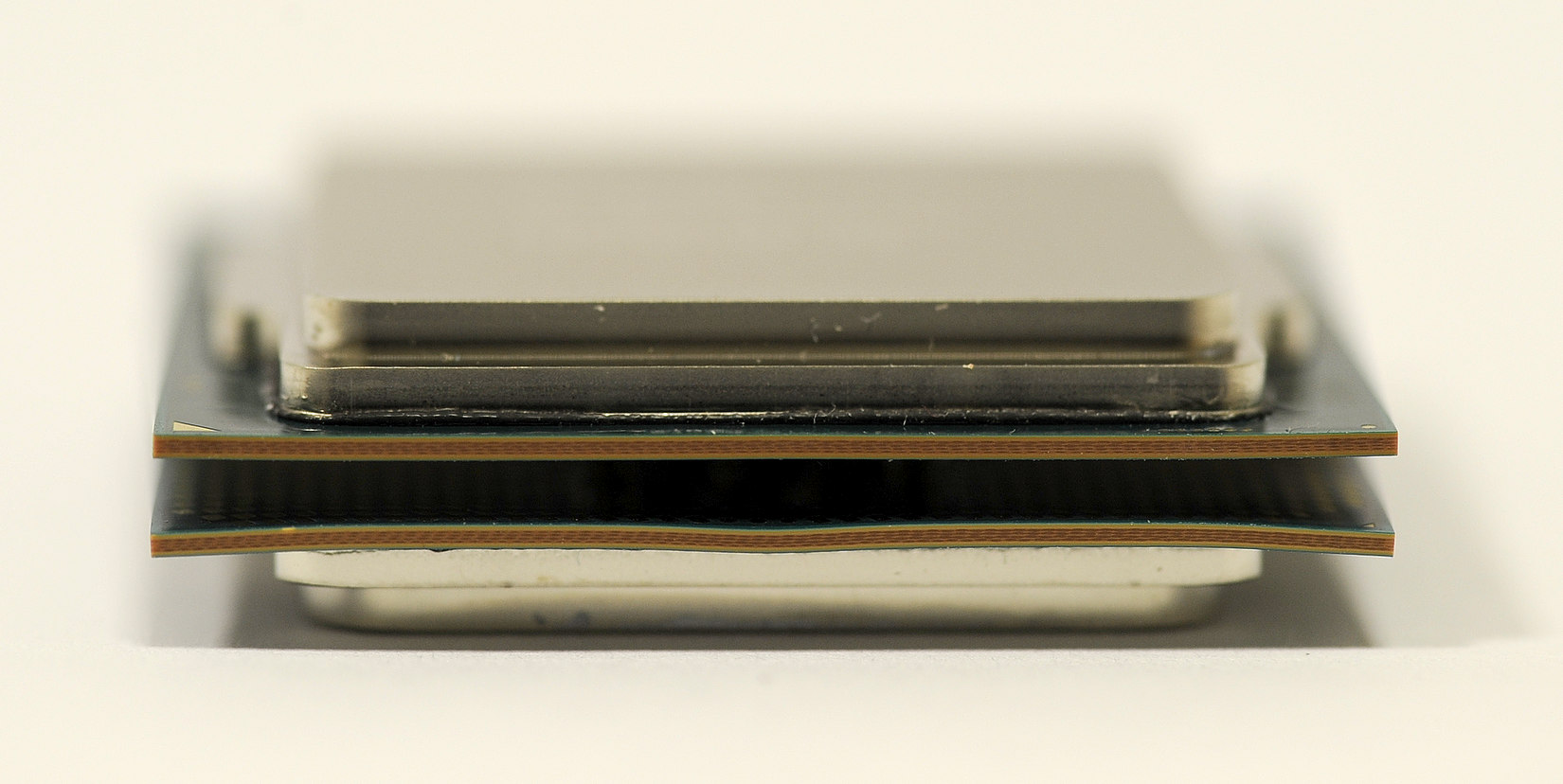

P.S. Added an image of my system that I took of it while bleeding. Is my setup completely wrong?

I recently decided to go down the custom water cooling route to challenge myself a bit. Long story short. I upgraded from a be quiet! Dark Rock Pro 3 to the following Alphacool NexXxoS Cool Answer 240 D5/UT - kit. I learned about all the basics that I had to know, watched lots of instructional videos and read tons of sites on the subject. I work in IT and have been building my own PC systems for the past 5 years, so I am no novice to PC hardware.

Here's a list of the Components in the water cooling kit:

1x Alphacool NexXxoS XP3 Light - Intel/AMD

1x Alphacool Repack - Single Laing D5 - Dual 5,25 Bay Station

1x Alphacool VPP655 - Single Edition

1x Alphacool NexXxoS UT60 Full Copper

3x Alphacool tubing AlphaTube HF 13/10 (3/8“ID) - clear

6x Alphacool HF 13/10 Anschraubtülle G1/4 - Deep Black

1x Alphacool NB-eLoop 1200rpm - Bionic Lüfter (120x120x25mm)

1x Alphacool CKC Cape Kelvin Catcher Clear 1000ml

1x ATX-bridging plug (24 Pin) - black

I have set everything up, bled the system for 48 hours making sure there are no leaks etc. However, now that I have my computer running, I ran AIDA64 and quickly discovered that my temps are through the roof. like, between 87°C and 98°C depending on the core.

I am running an Asus ROG Z170 Maximus VIII Hero Motherboard with an Intel Core i7 6700K Processor in a Corsair Obsidian 750D. I tested out different clocks from 4.0GHz to 4.6GHz which has been running stable for the past 4-5 months. The i7 does NOT throttle or crash, the temps are simply really high.

I just can't figure out why the temps would be so high. I reseated the CPU cooler, applied a different and new type of thermal paste (because my other tube was 5 years old, who knows), set the fans to max settings, air is coming through the radiator.

Is my pump broken? Since this was the first time doing a water cooling loop, I turned the PSU on and off to allow the water to go through all of the components in the loop. I got a little ambitious and it took me about 4 seconds to realize what a dry pump sounds like *eeeeek*. Should I invest in a flow meter? but when I turn up the pump speed to max, air disturbance gets pumped through the loop which I can visually see moving around at a seemingly fast speed. Also the pump has no rattling noise or anything that I wouldn't think is normal operating sounds. Is the pump ruined from 4 seconds of dry running?

Is my motherboard broken? Is it possible that my motherboard is broken? ESD? I wouldn't think so since my system is stable, simply running hot.

Is my CPU broken? Could I have fried my CPU? When I still had my be quiet Dark Rock Pro 3, I used Asus' Dual Intelligent Processor 5 to OC my CPU (I know I know...) but it worked and settled at 4.7-4.8, but I set it to 4.6 just to be 100% stable at all times. Now, with my custom loop, when I run Dual Intelligent Processor 5 to OC my CPU, it cancels on the first run through and doesn't actually test to see if the CPU is able to go to any higher clocks than the mildest overclock which is 7%. The nature of the program is that it simply reboots, and goes to the next step in the OC process which is determining the fan settings, so I don't get an error message or failed etc.

Are my Alphacool NB-eLoop 1200rpm fans ? I feel air coming through the rads, but I don't know if it's enough. Even at full speed, the temps go up to 90°C.

So guys, hope you have your Sherlock hats and pipes ready, as I appreciate every single one of you who reads through this wall of text and tries to help me solve this.

Cheers,

baN

P.S. Added an image of my system that I took of it while bleeding. Is my setup completely wrong?

Last edited by a moderator: