Ace_finland

New member

Hey guys,

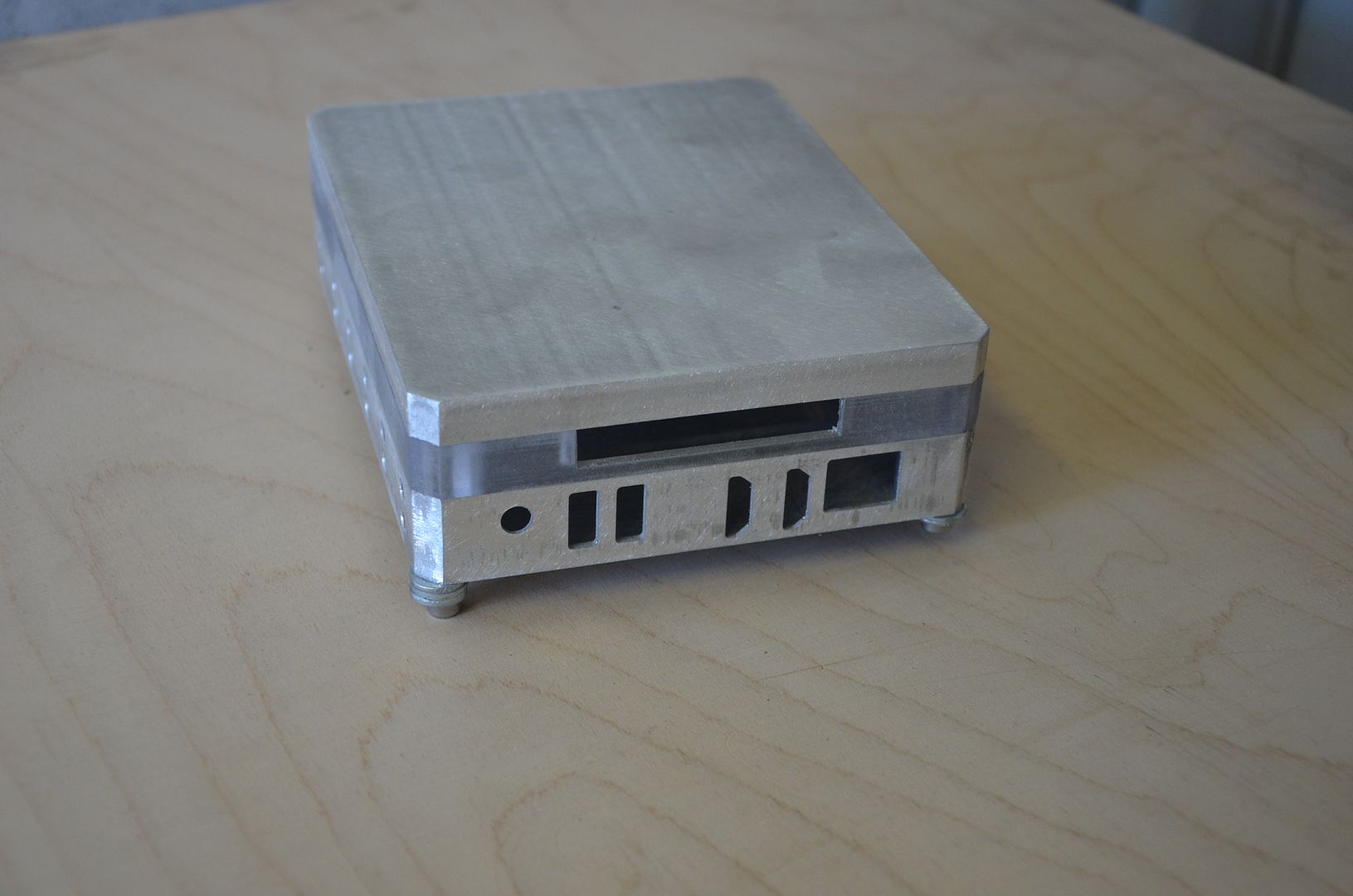

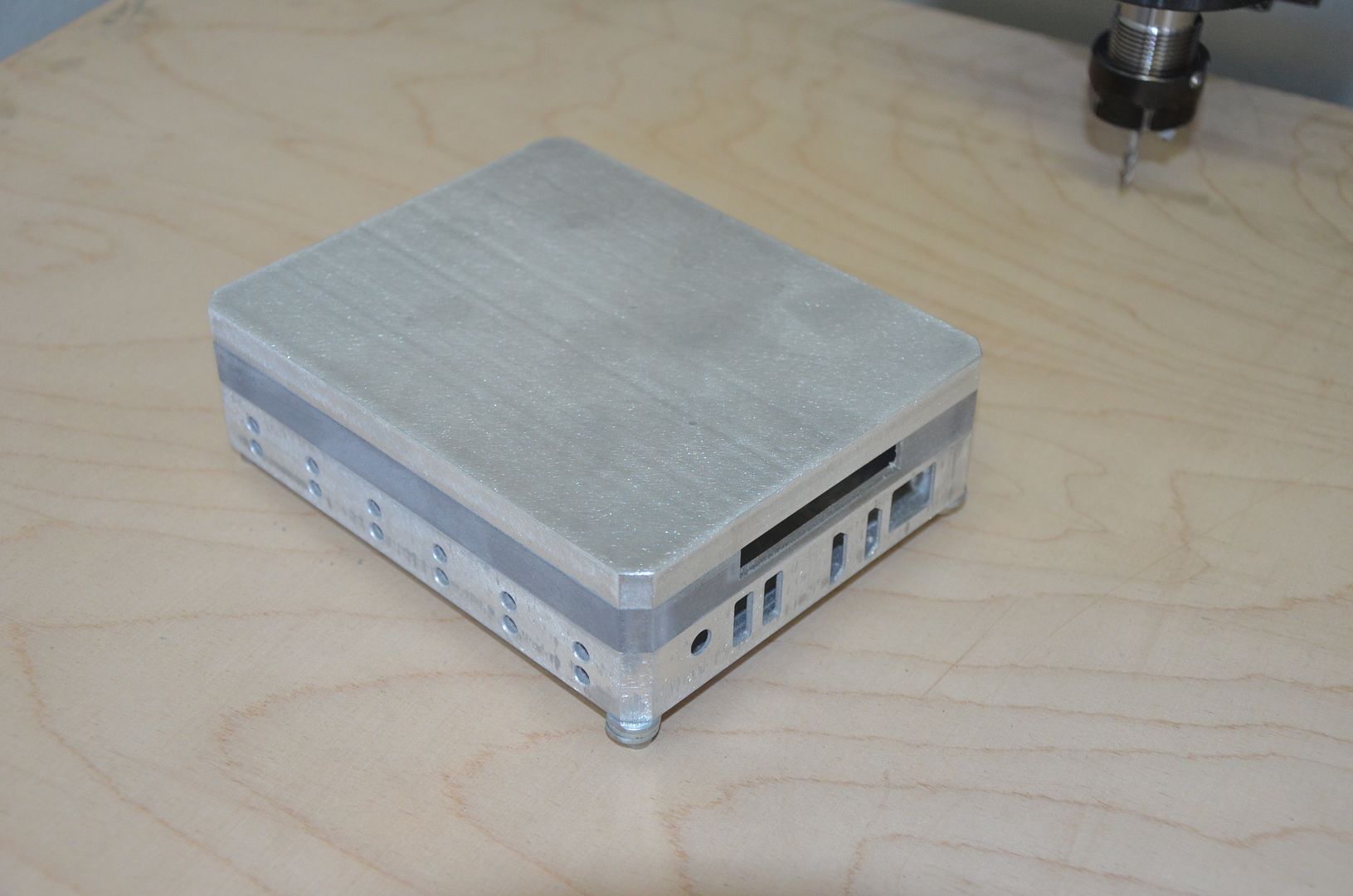

For a long time i've been wanting to make a small pc for the tv so when i saw the announcement of the Intel NUC/Bit-tech competition i thought i would send in a design and see how it goes. Sadly I didn't get picked for the competition but in the true spirit of modding i bought all the parts instead so i can still make a case.

Background:

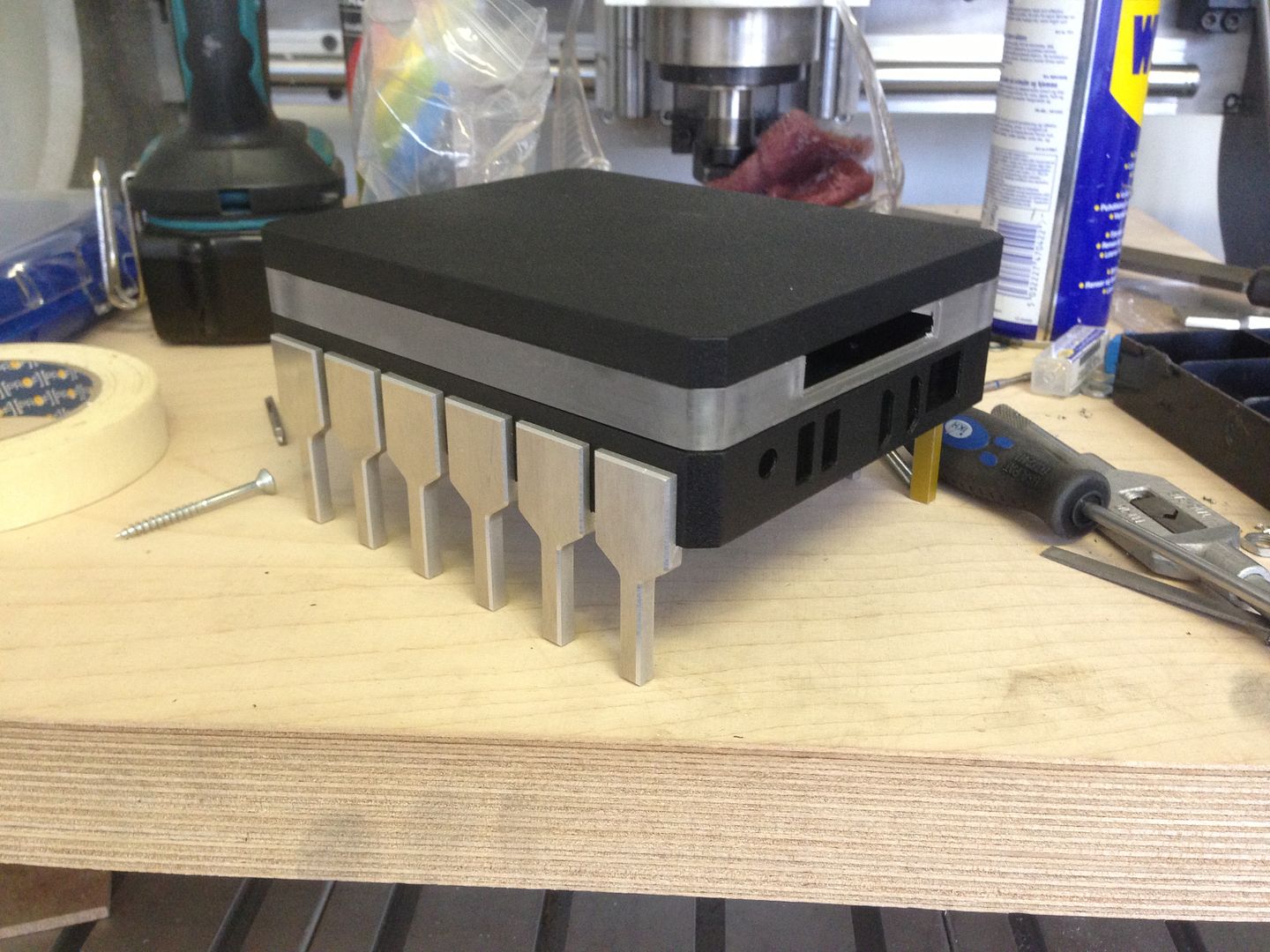

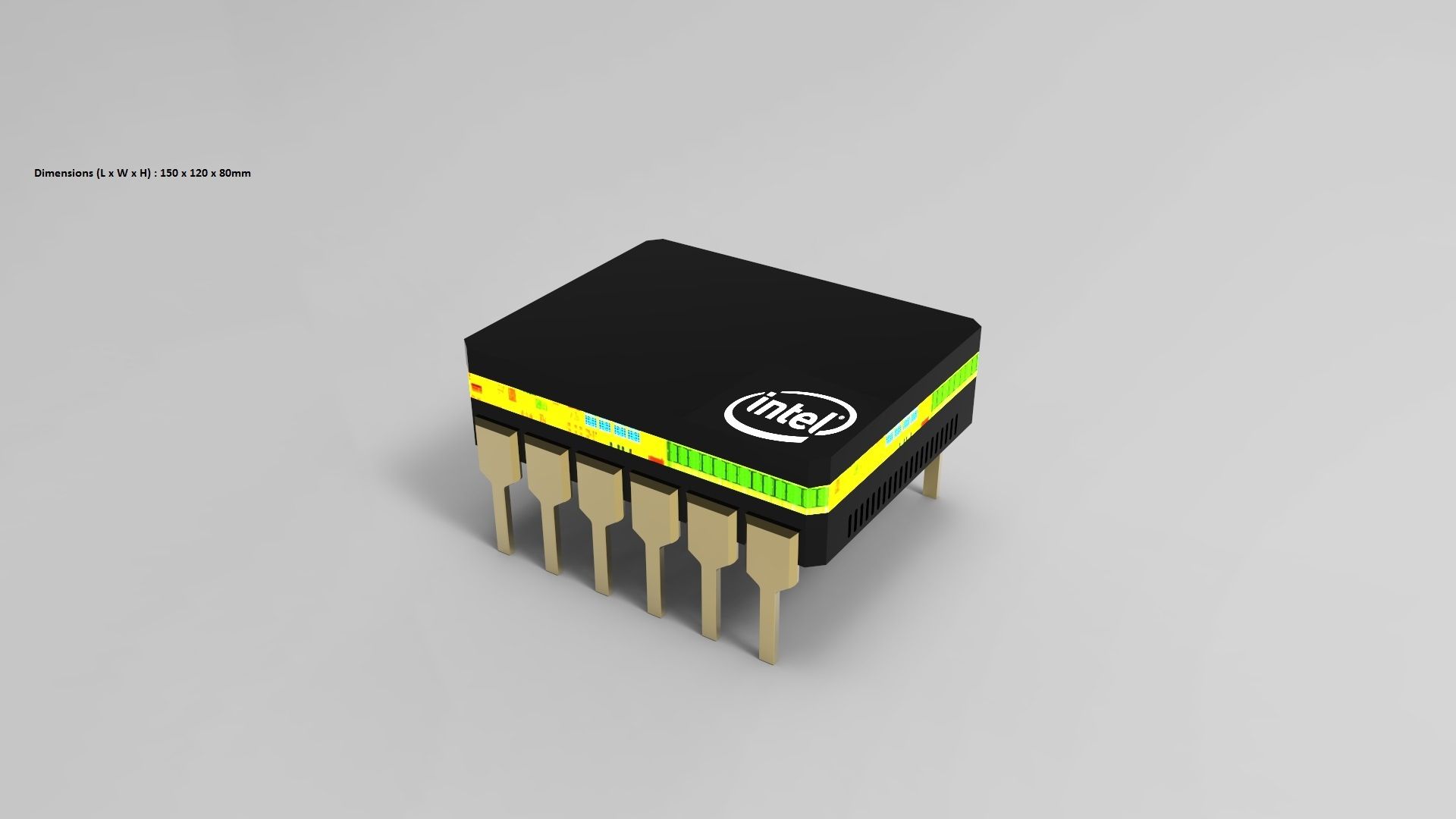

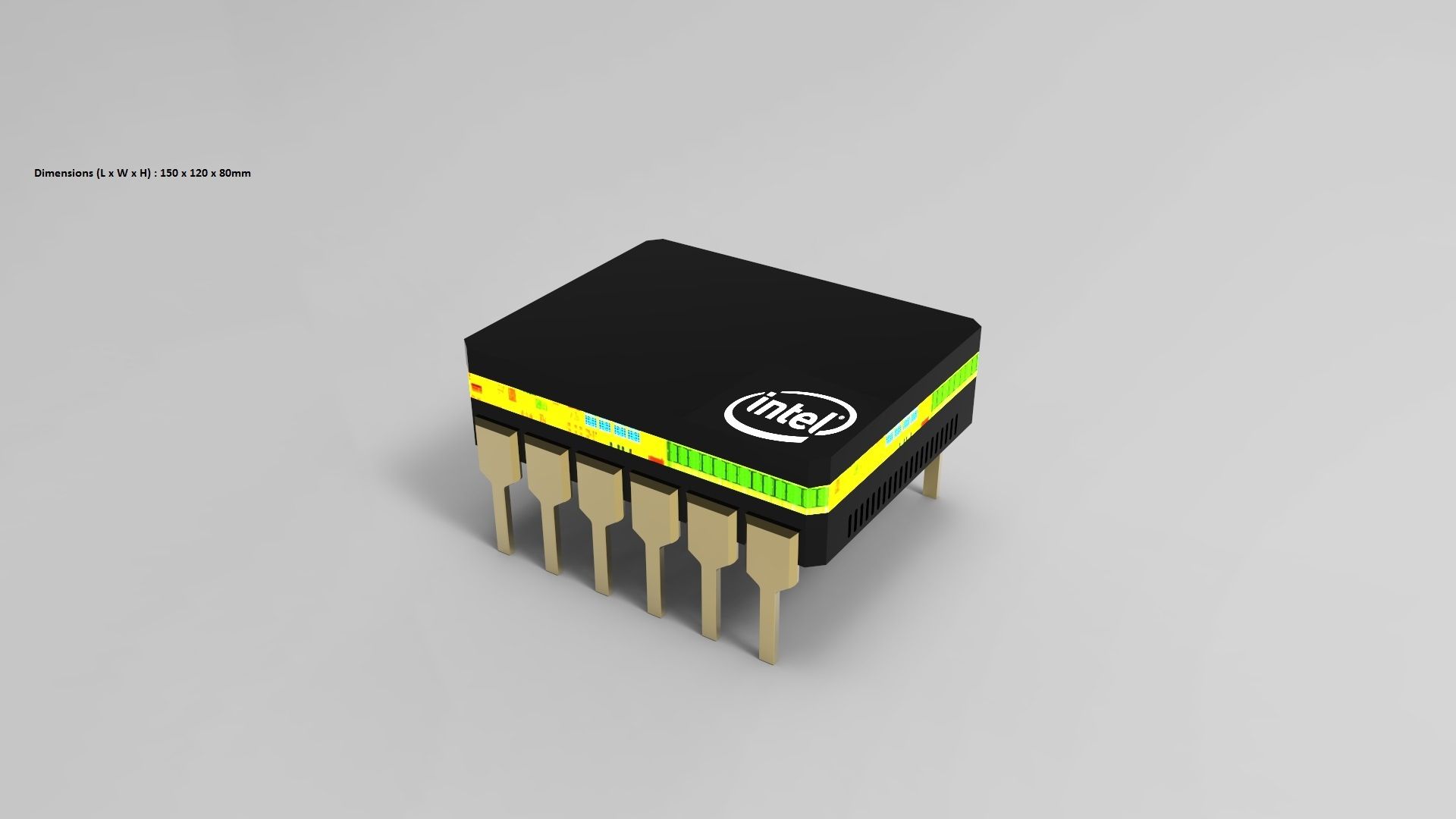

When i first saw the Intel NUC and its small size i knew it would be perfect for my needs. When thinking of a design for the competition i started looking at Intel's old microprocessors and what they meant for the general public back in the days. These nuc motherboards are a bit of the same in my mind seeing they are quite powerful for their very small form factor. Anyways, enough of that

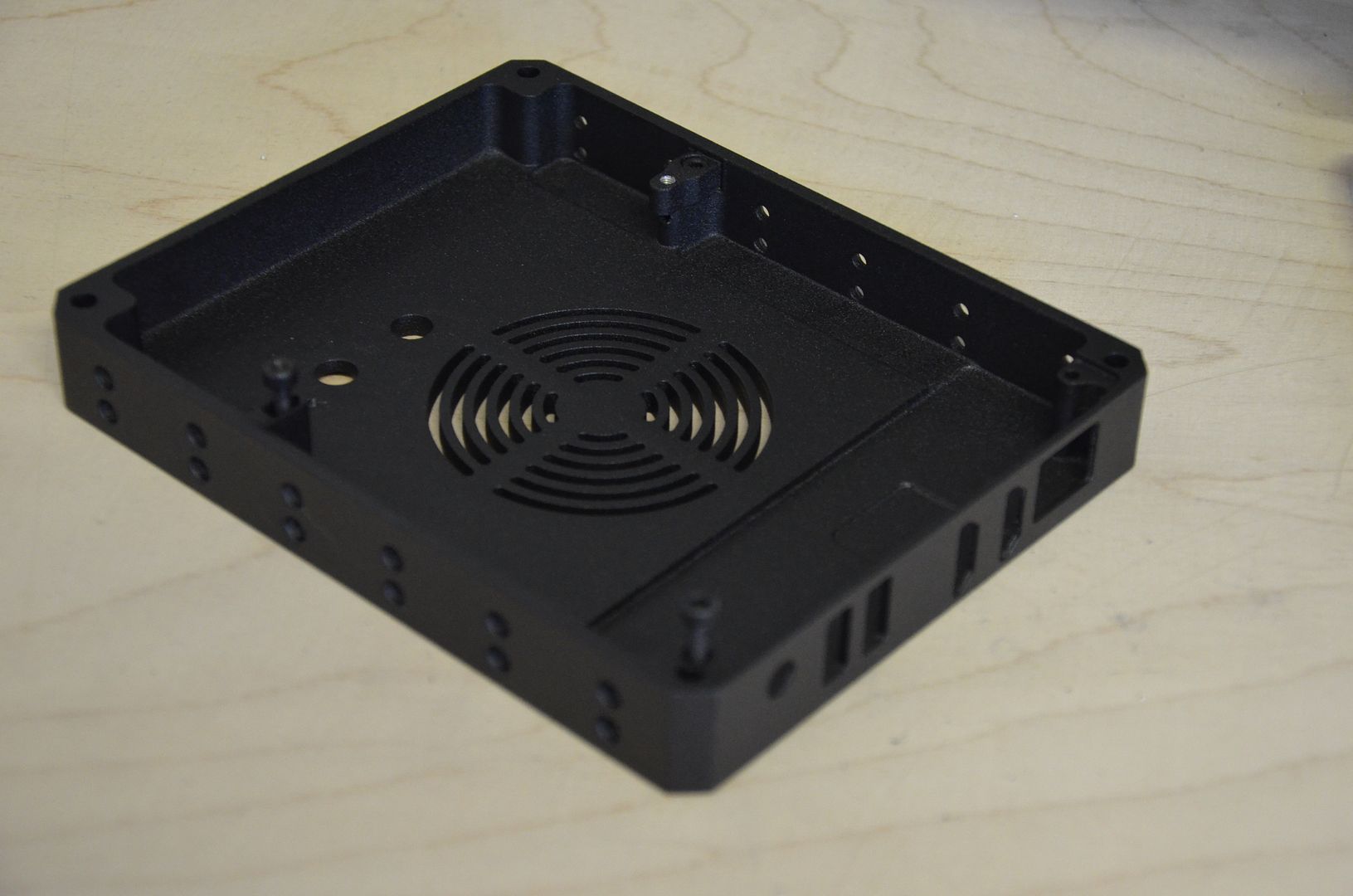

This is the design i sent in for the competition. It has changed quite a bit but i don't have any better ones.

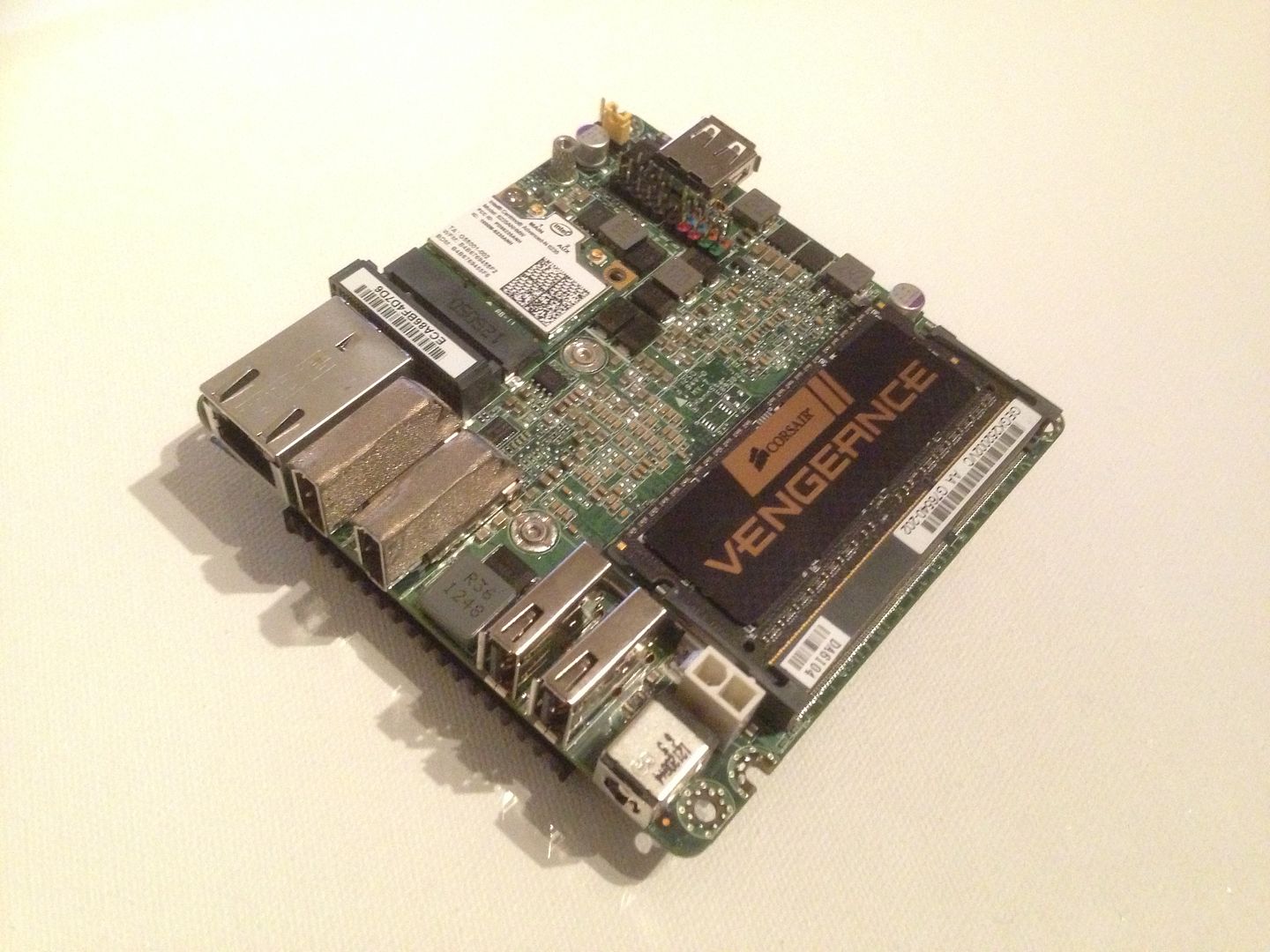

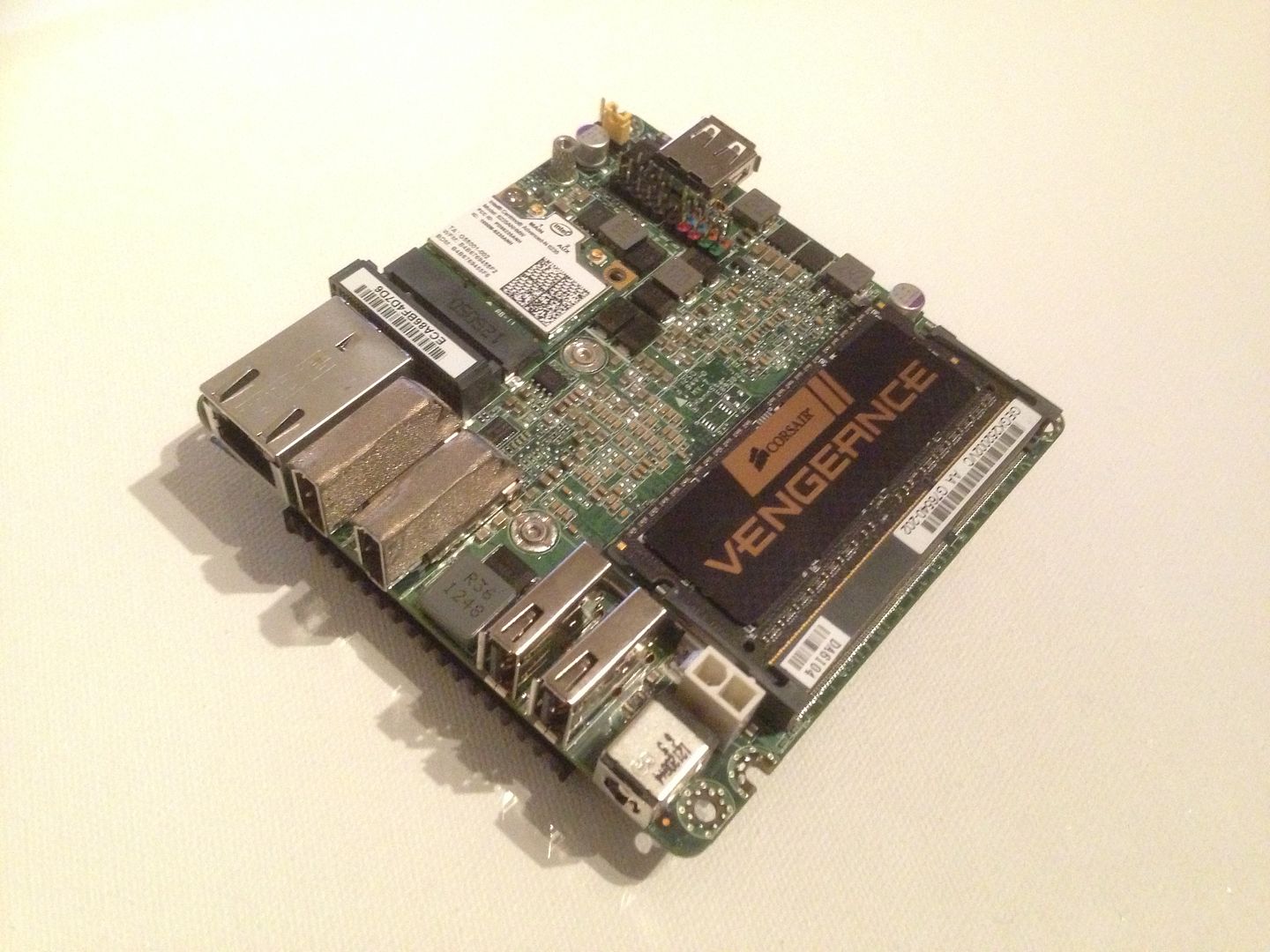

Decided on a different version (still an i3) but with an wired network and no thunderbolt as i have no need for thunderbolt as of now and it was a bit cheaper

Nuc, 8GB of vengence 1600 ram and a wireless & BT card from Intel

120GB Kingston SSD

Now that that is over lets start with the build pictures

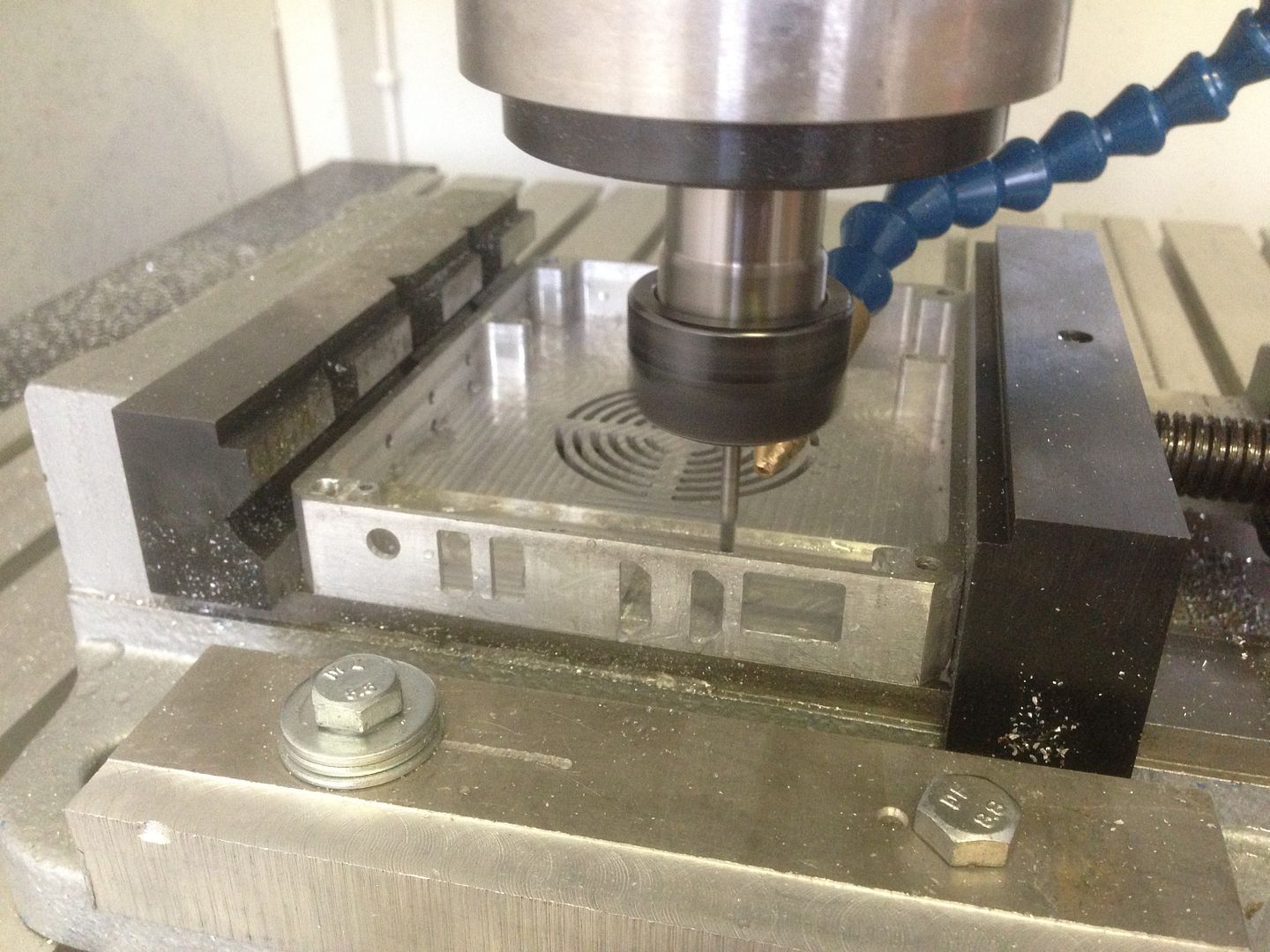

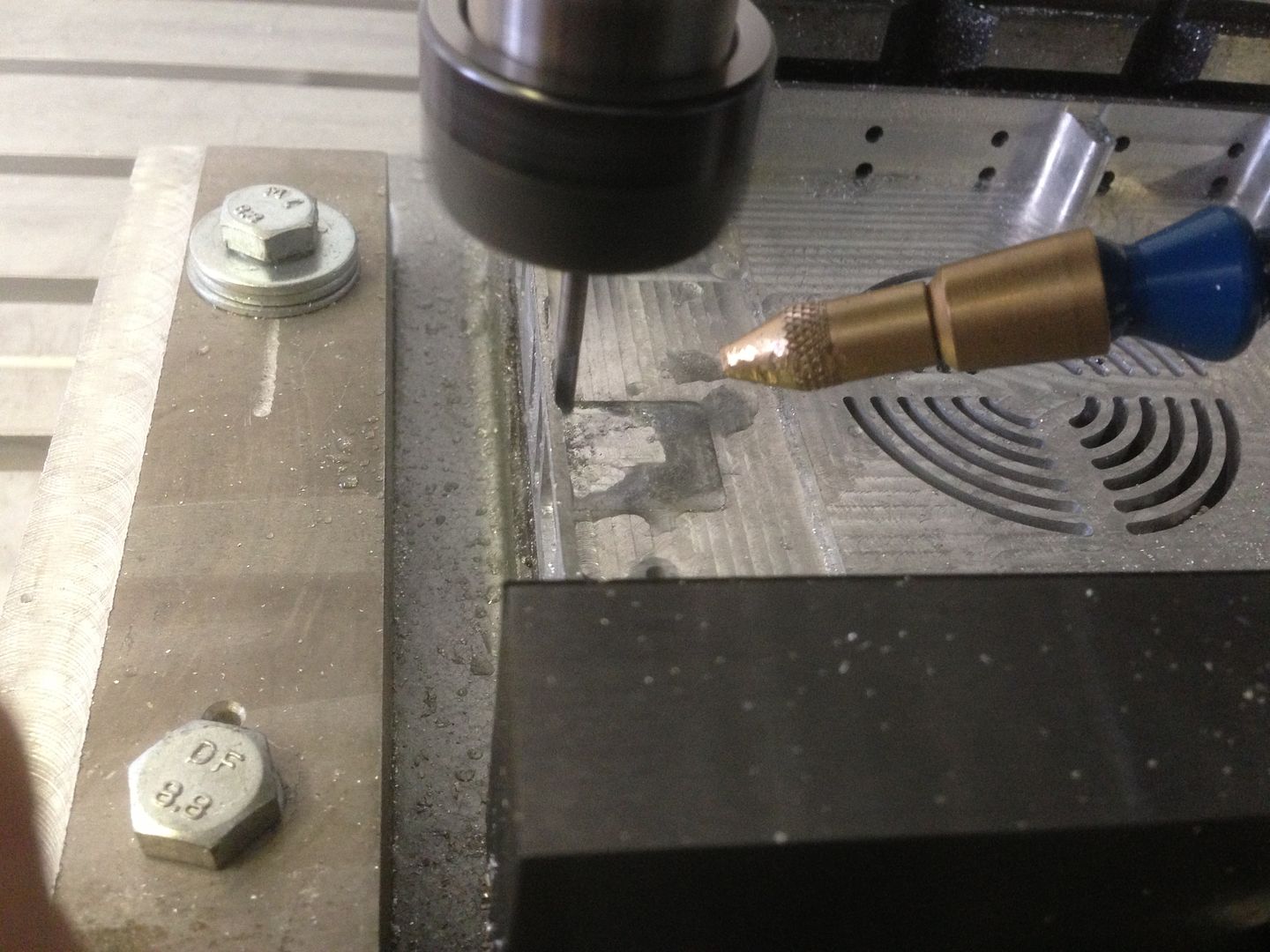

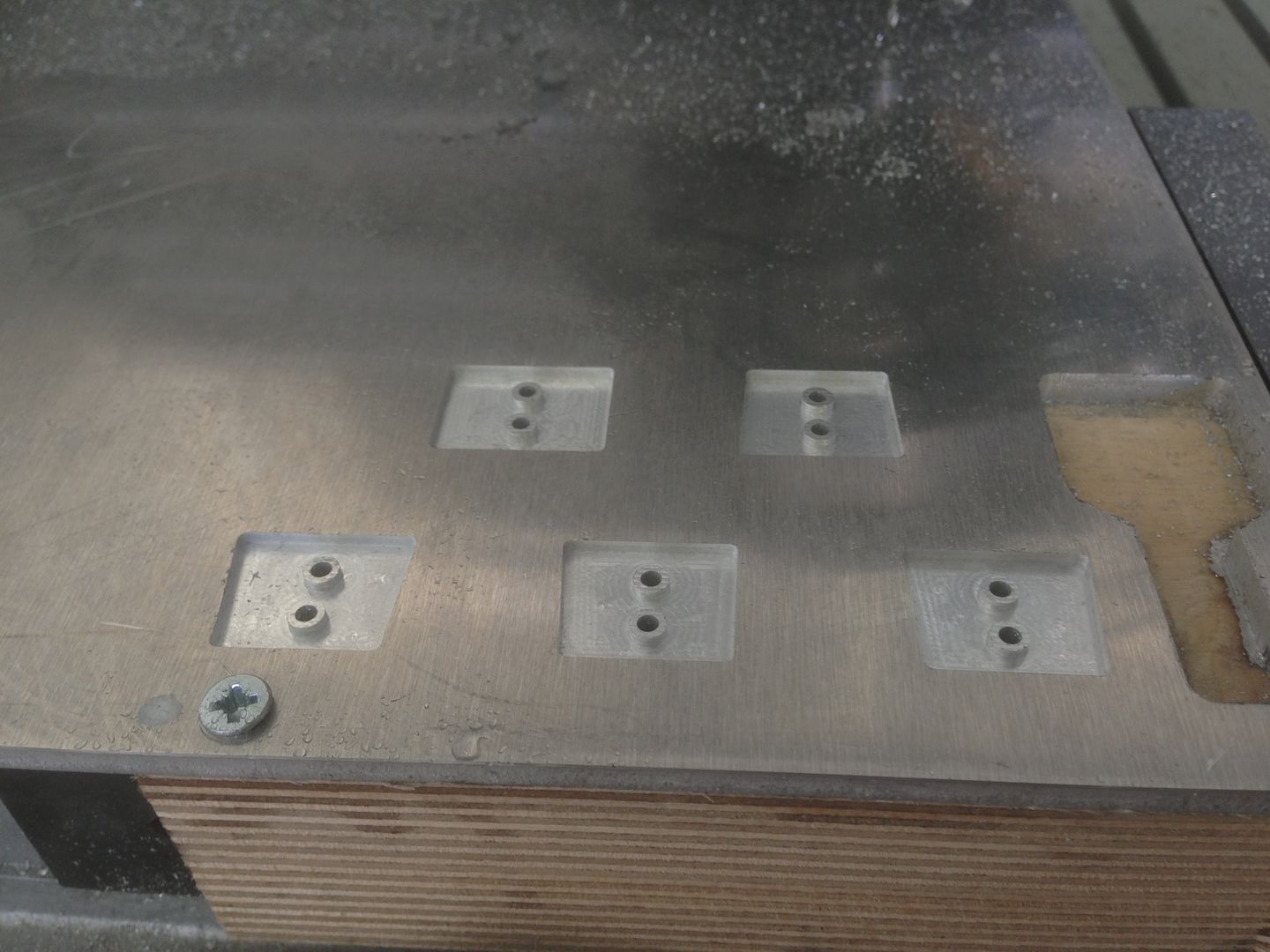

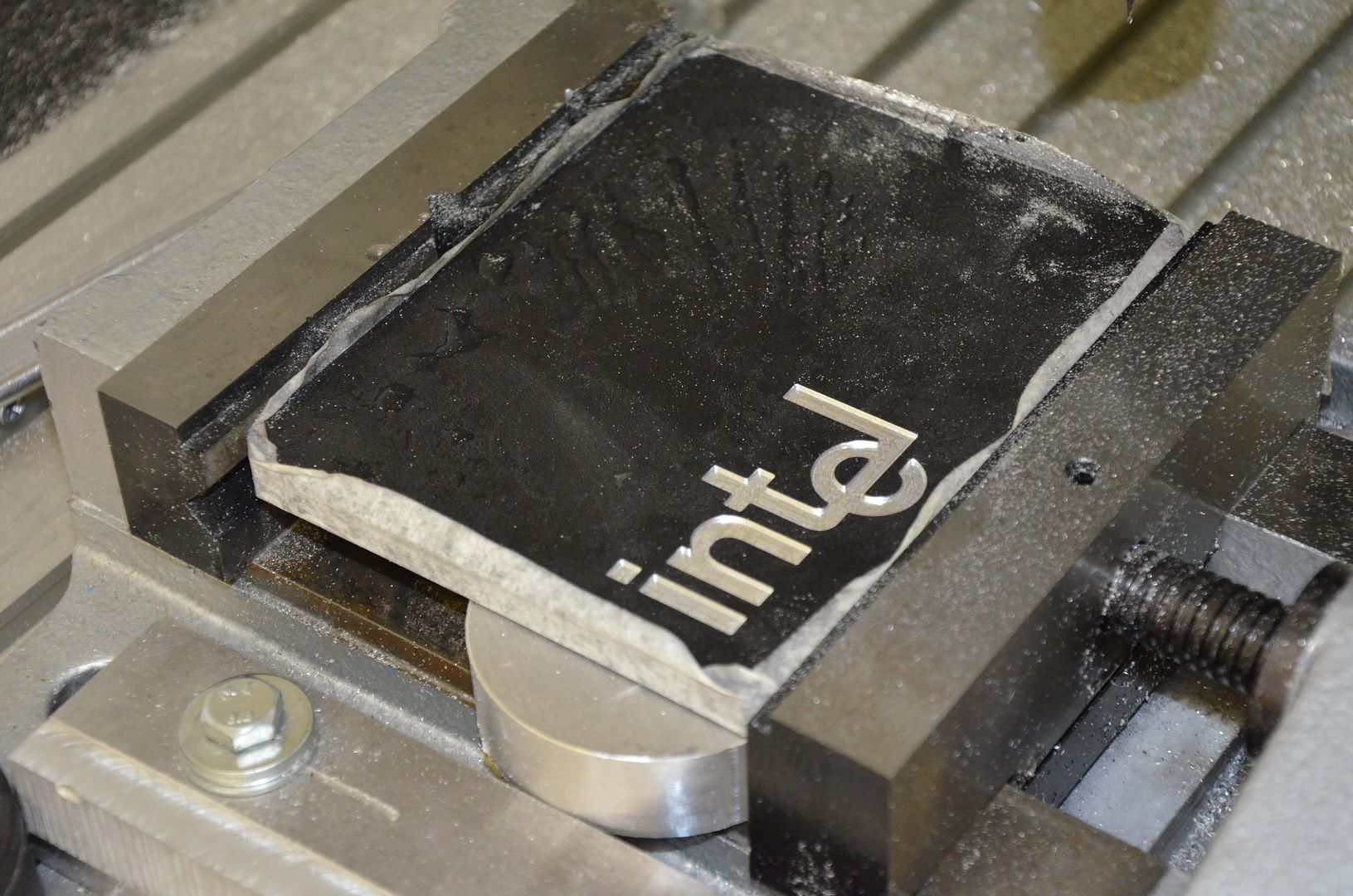

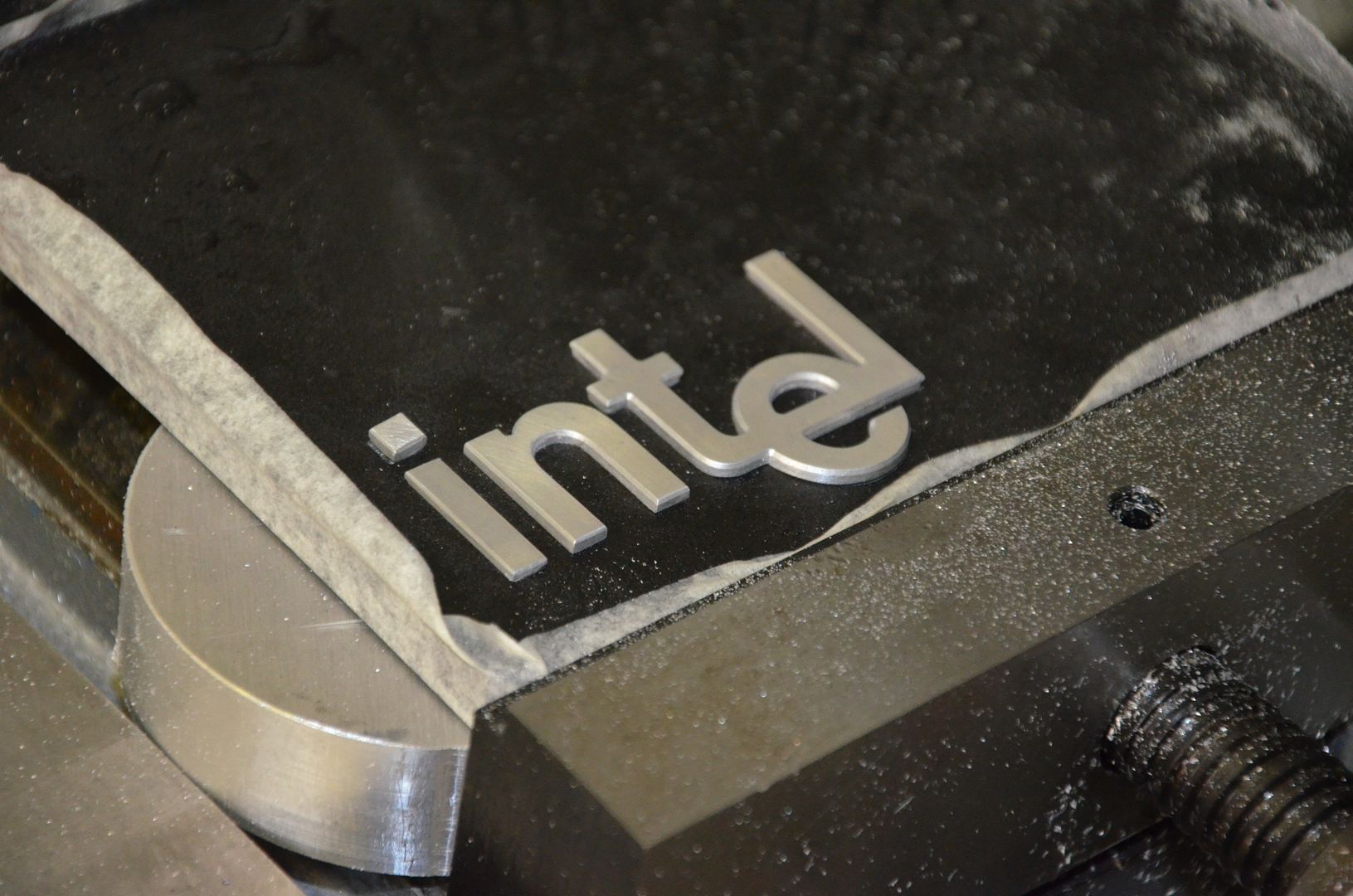

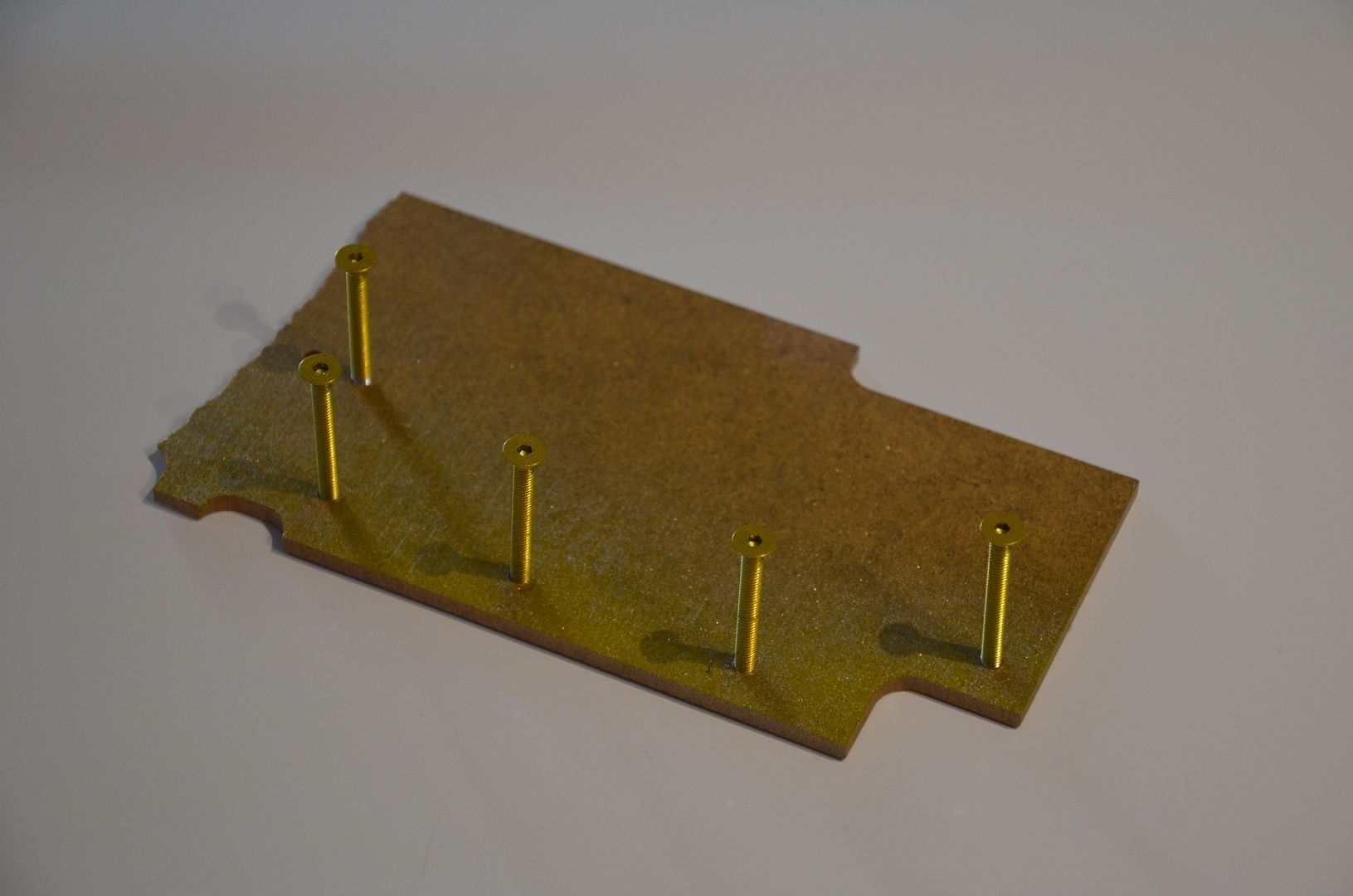

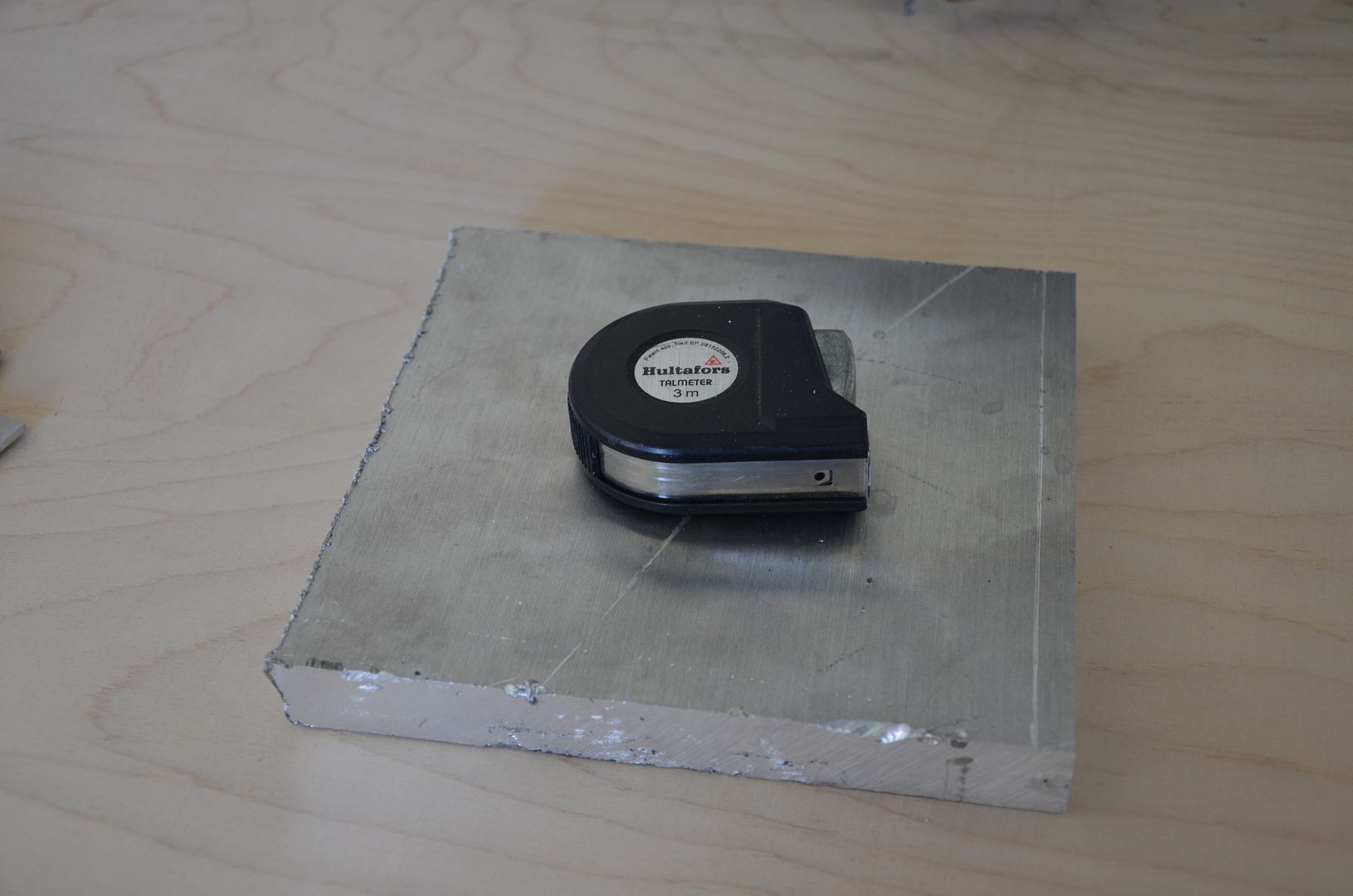

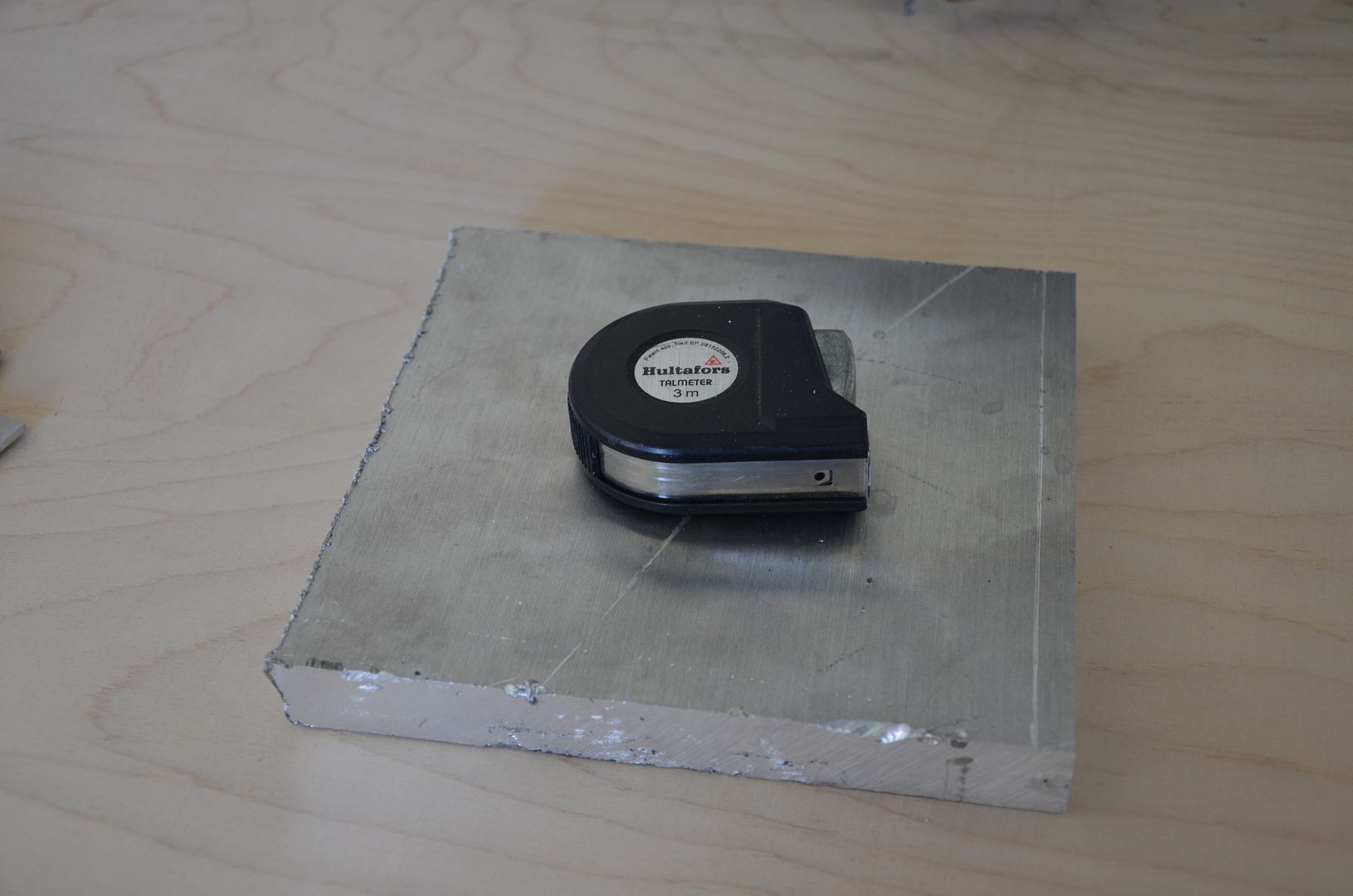

200x200x20mm piece of aluminum cut with a circular saw, worked a lot better than i thought it would.

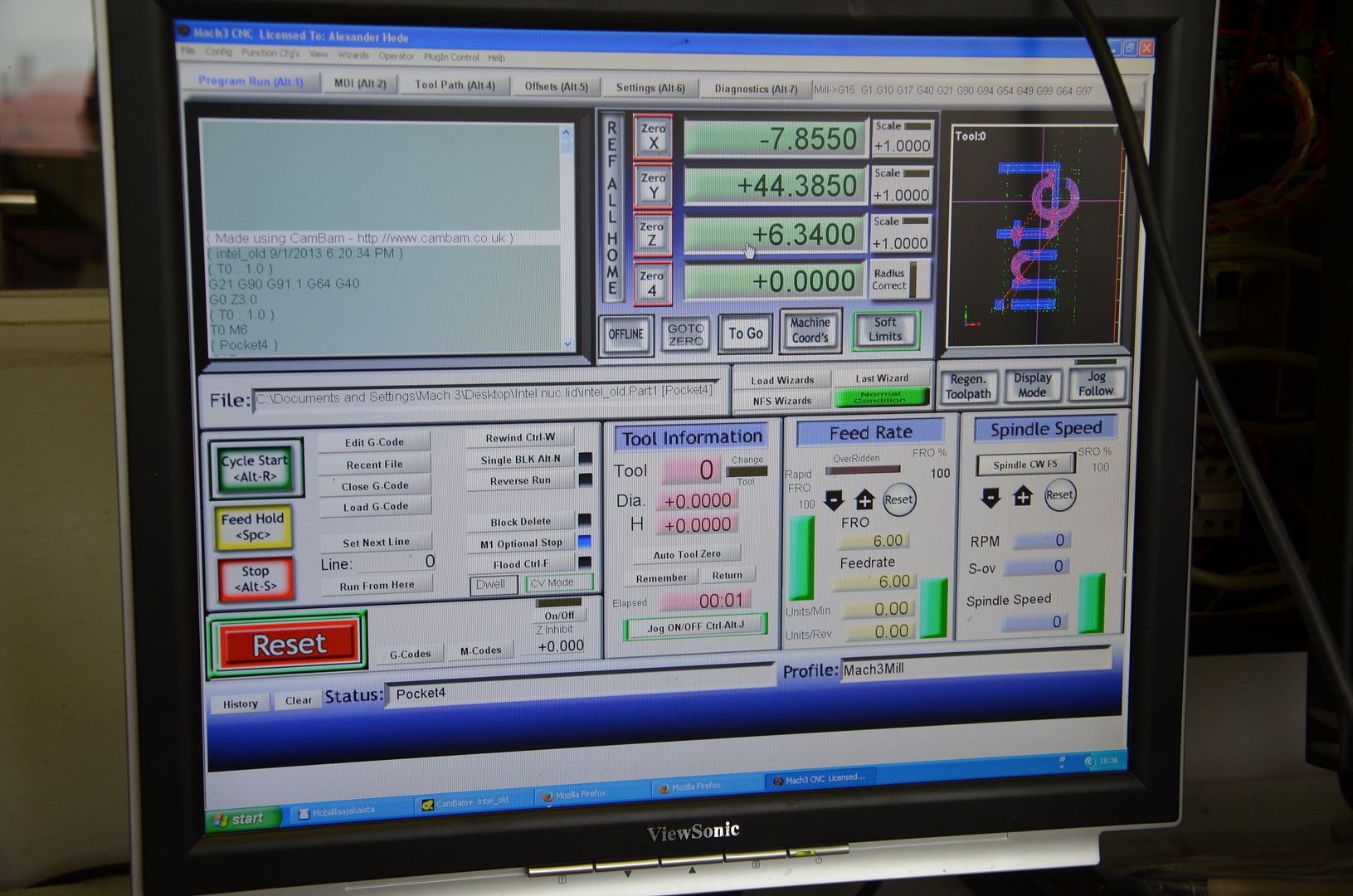

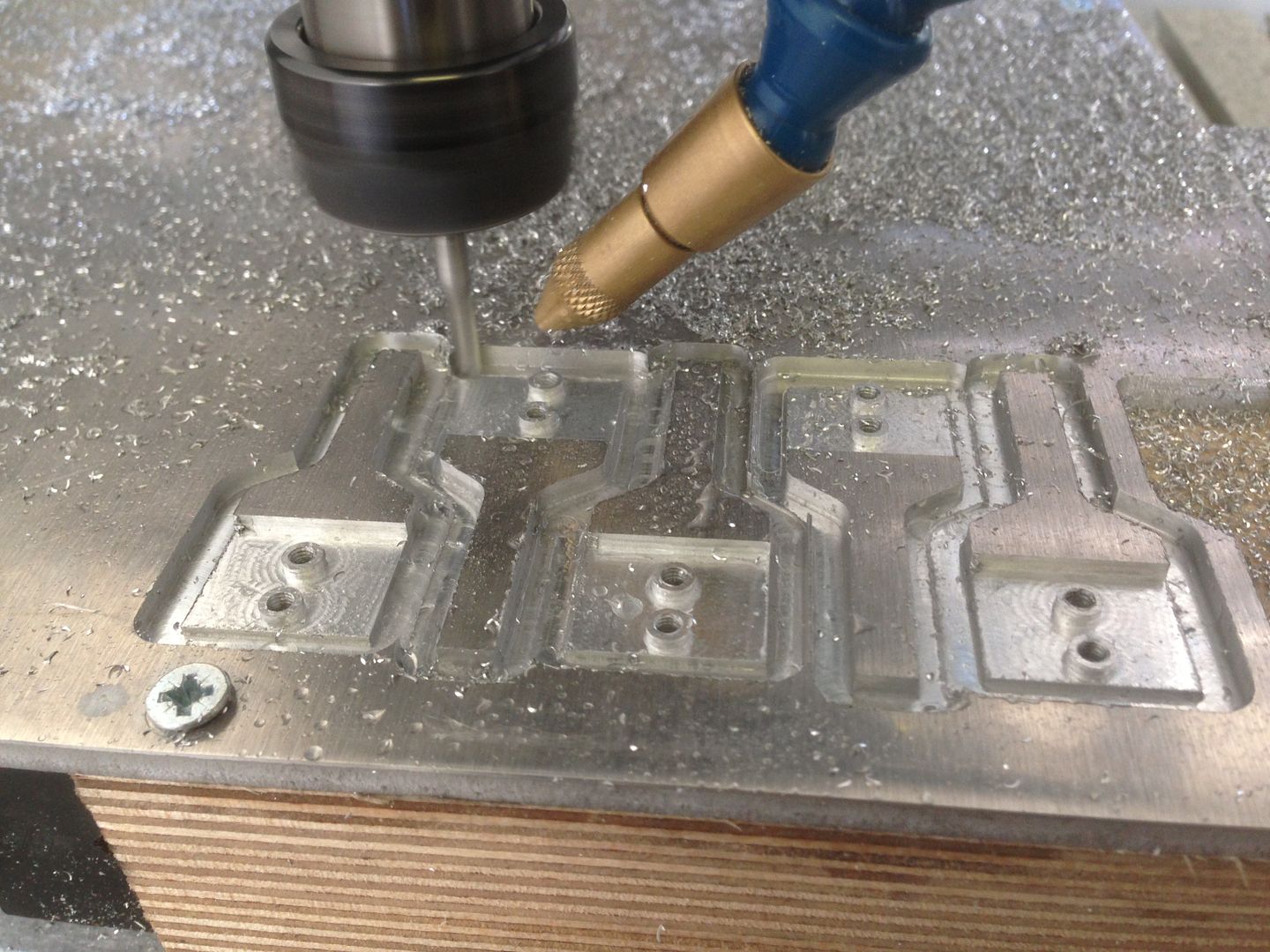

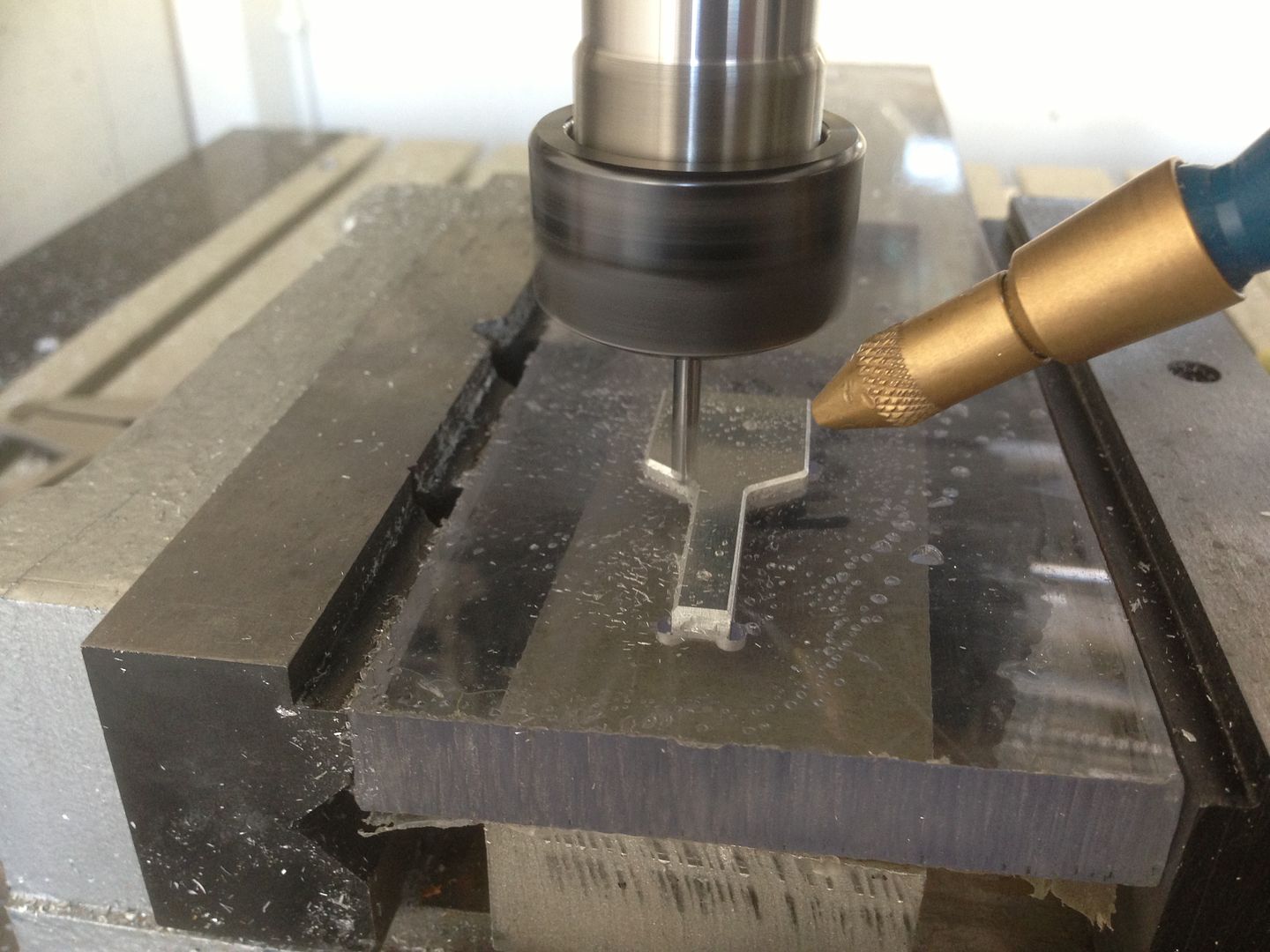

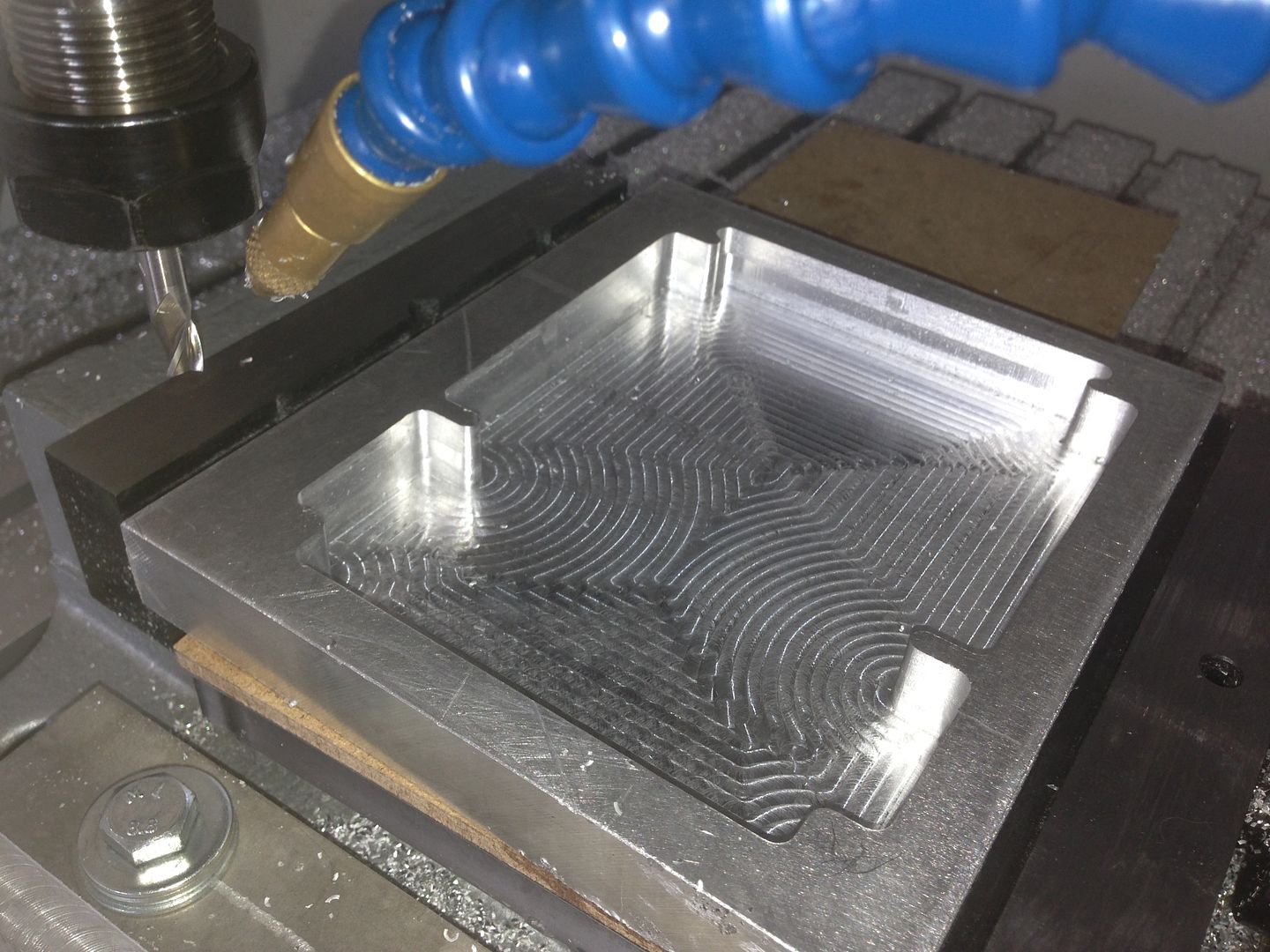

As i recently finished upgrading my homebuilt CNC mill/router i thought i would put it to the test during this build

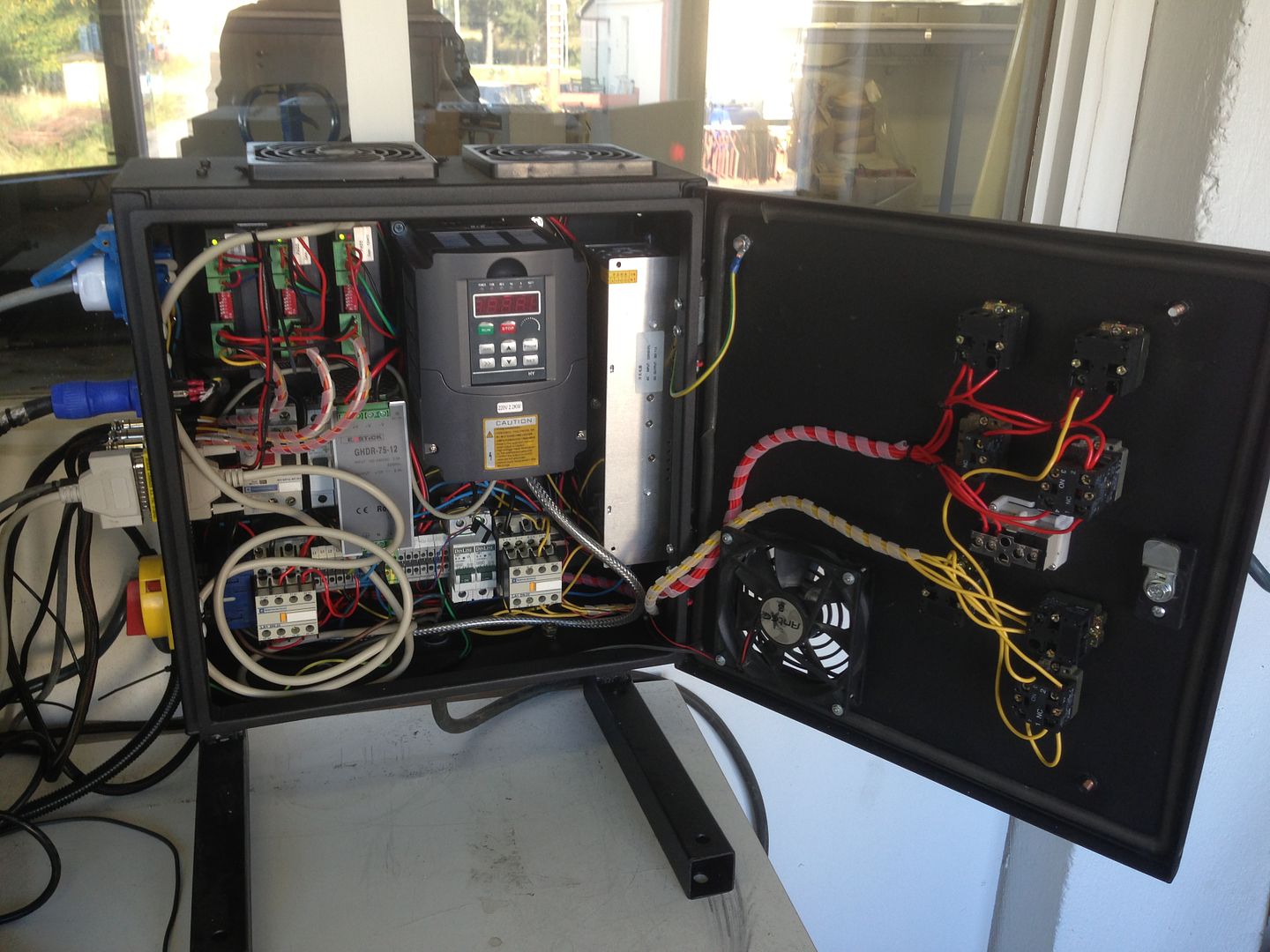

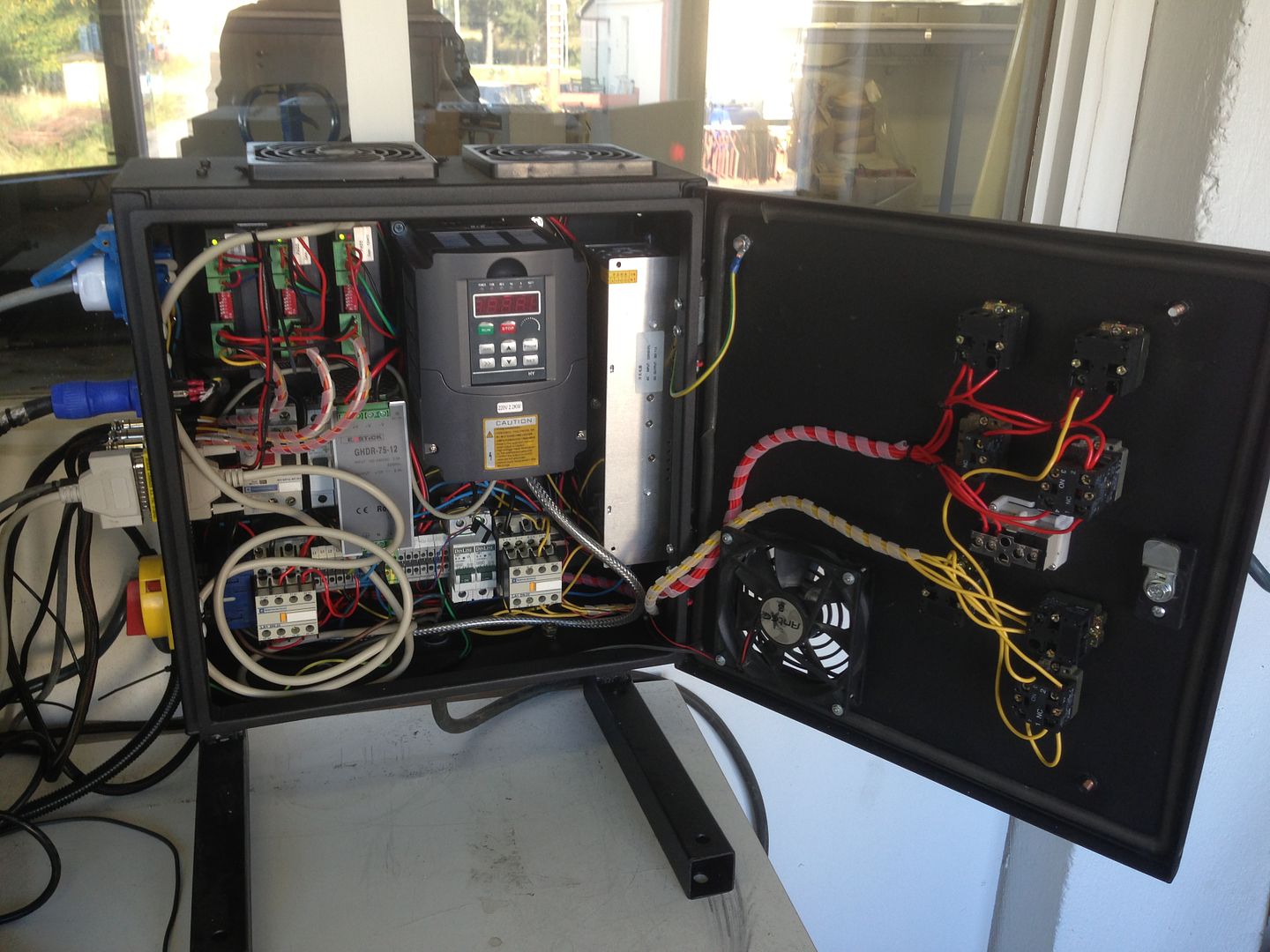

The Mill

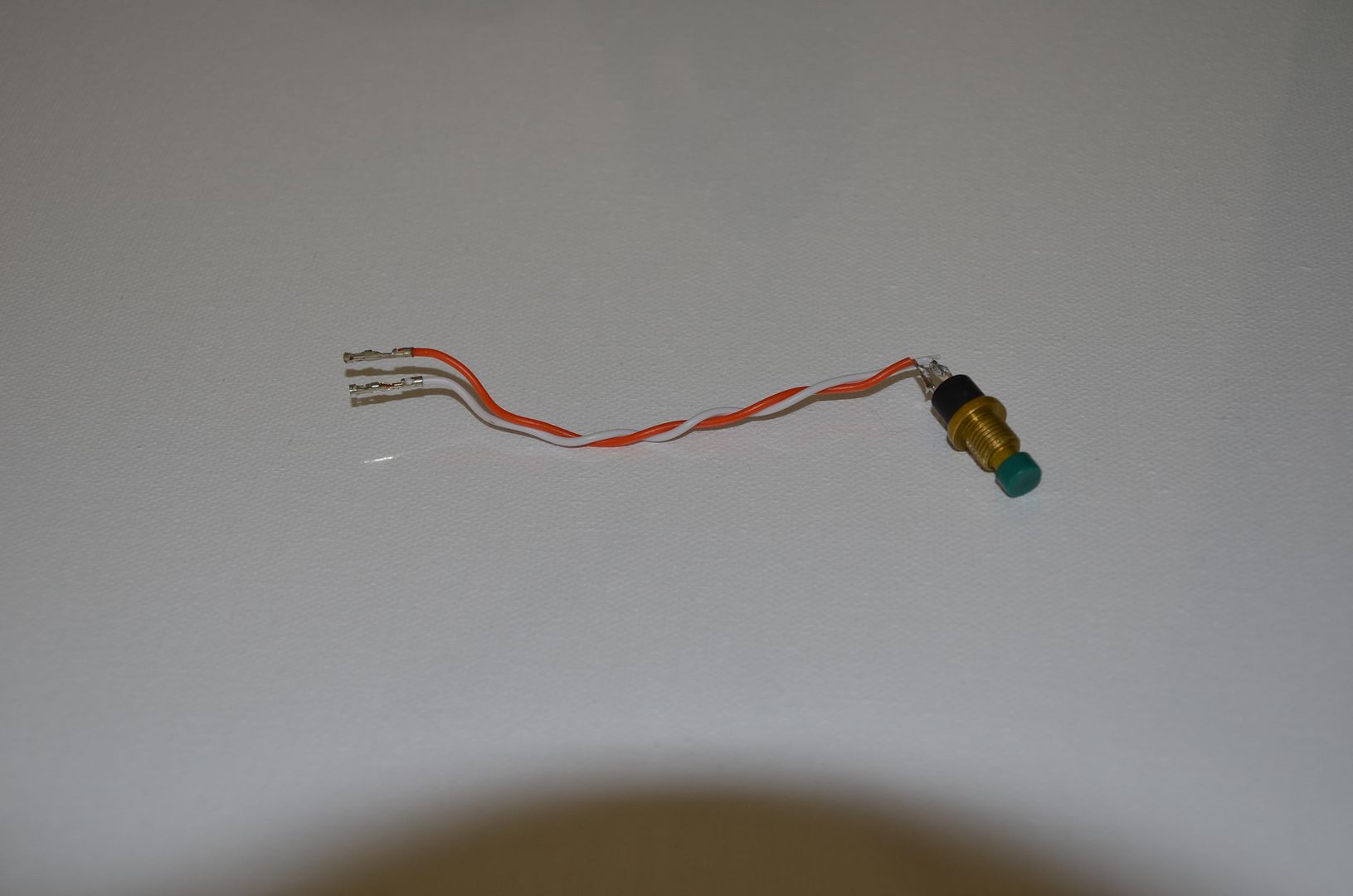

Took me a while with the electronics since im no electrician and don't have a lot of skills with it, luckily no smoke

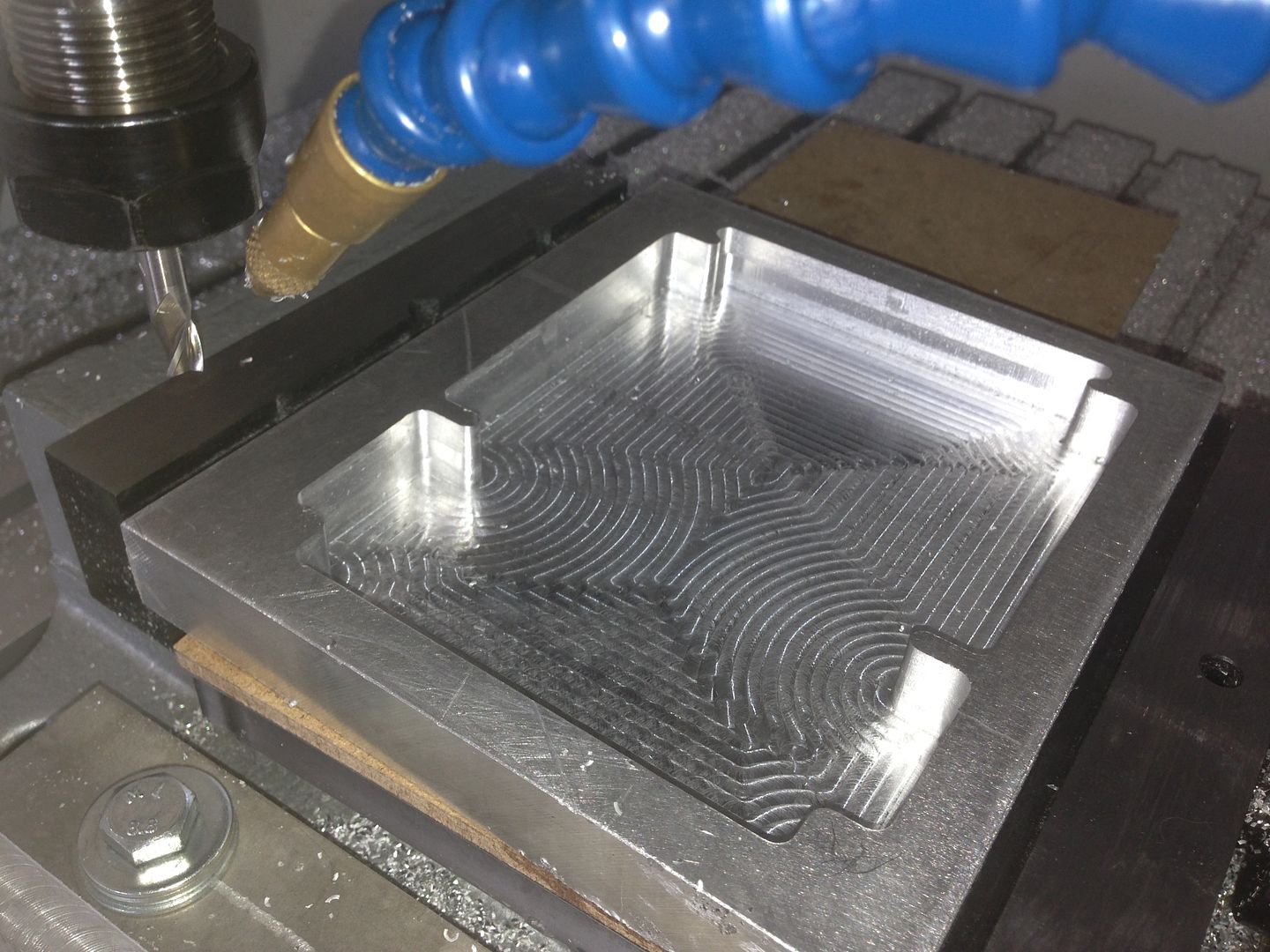

A bit of roughing with a 6mm endmill

More pictures soon as i have gotten a bit further than this.

Hope you like it and please drop a comment

For a long time i've been wanting to make a small pc for the tv so when i saw the announcement of the Intel NUC/Bit-tech competition i thought i would send in a design and see how it goes. Sadly I didn't get picked for the competition but in the true spirit of modding i bought all the parts instead so i can still make a case.

Background:

When i first saw the Intel NUC and its small size i knew it would be perfect for my needs. When thinking of a design for the competition i started looking at Intel's old microprocessors and what they meant for the general public back in the days. These nuc motherboards are a bit of the same in my mind seeing they are quite powerful for their very small form factor. Anyways, enough of that

This is the design i sent in for the competition. It has changed quite a bit but i don't have any better ones.

Decided on a different version (still an i3) but with an wired network and no thunderbolt as i have no need for thunderbolt as of now and it was a bit cheaper

Nuc, 8GB of vengence 1600 ram and a wireless & BT card from Intel

120GB Kingston SSD

Now that that is over lets start with the build pictures

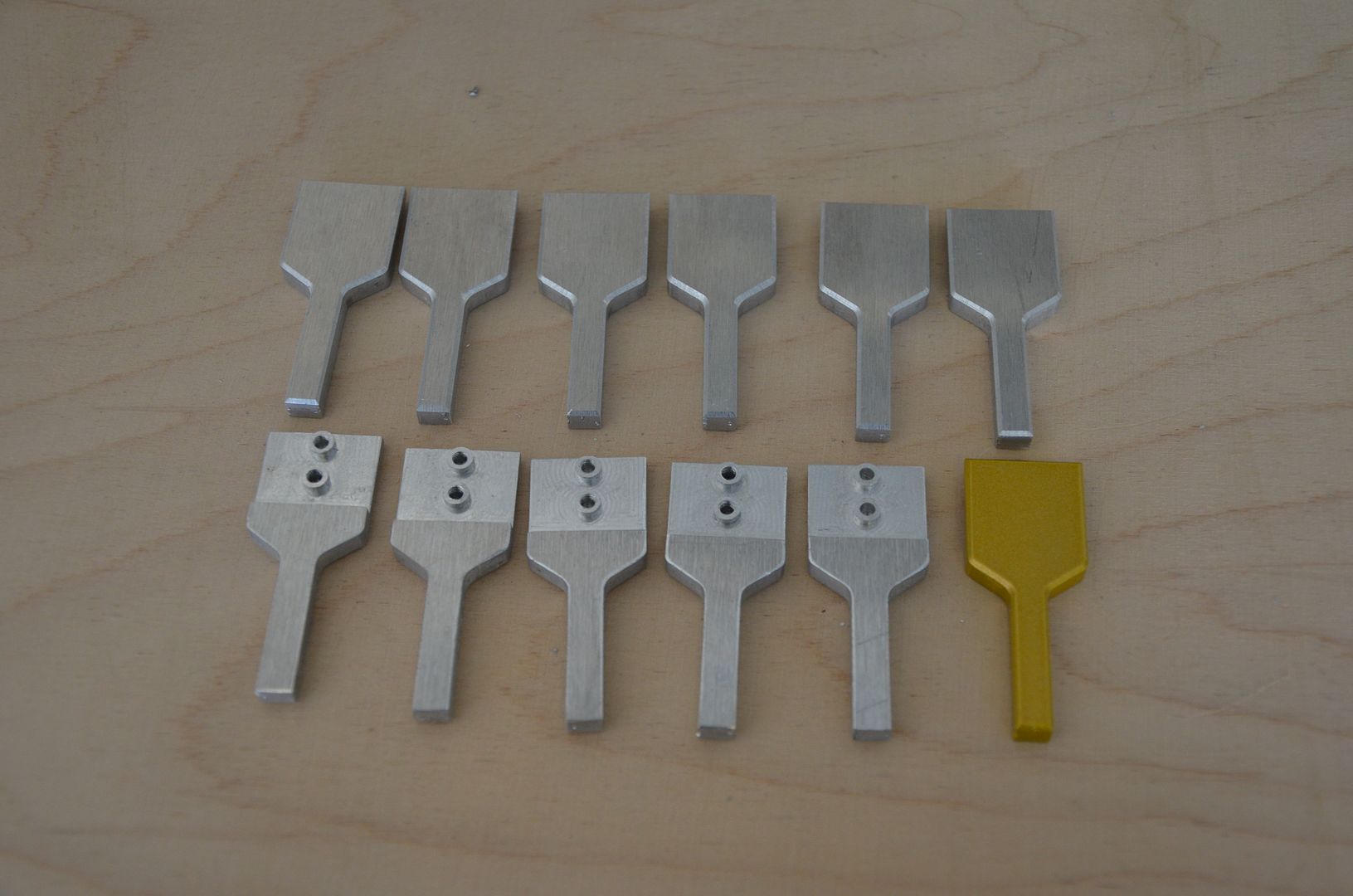

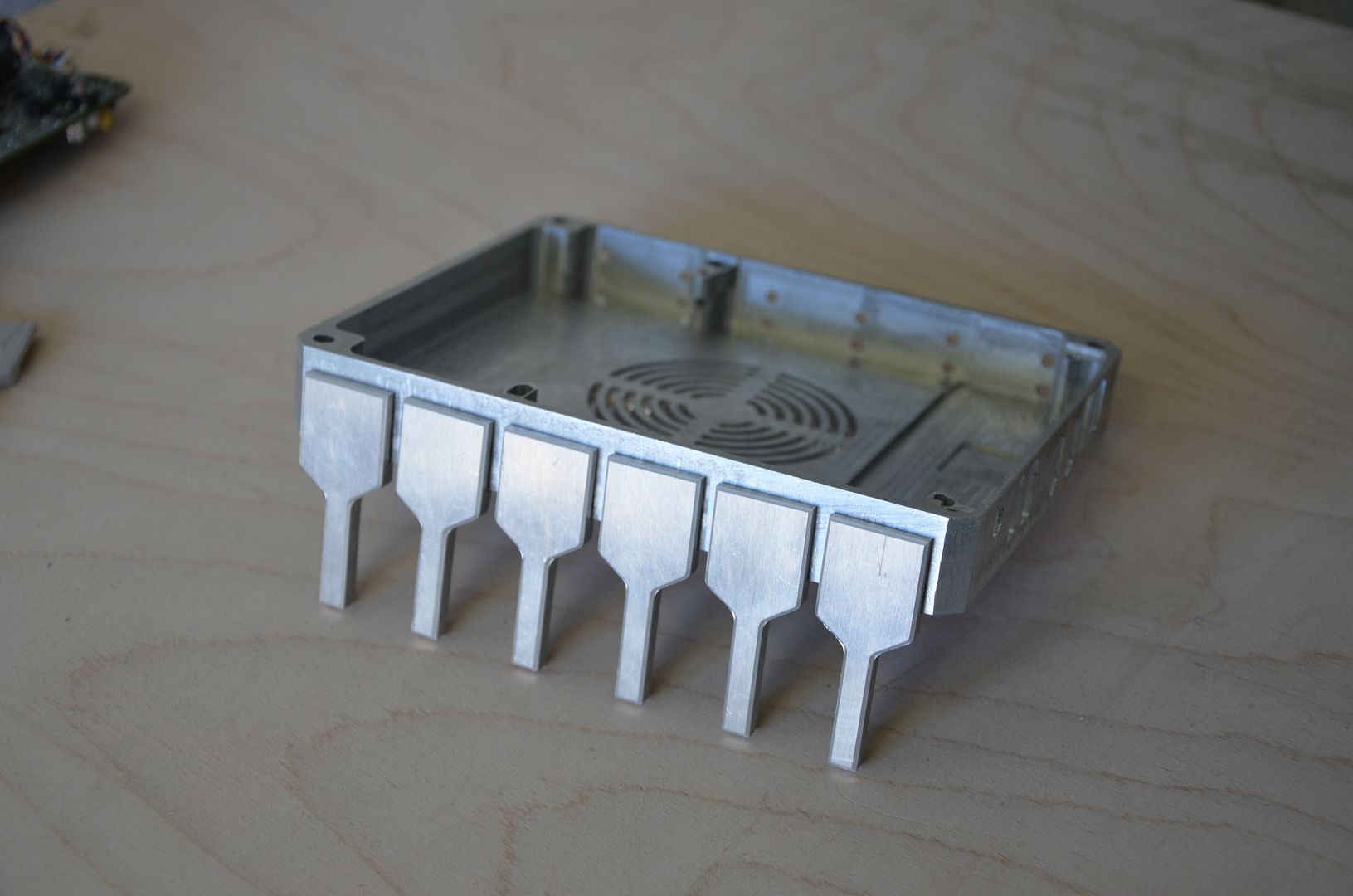

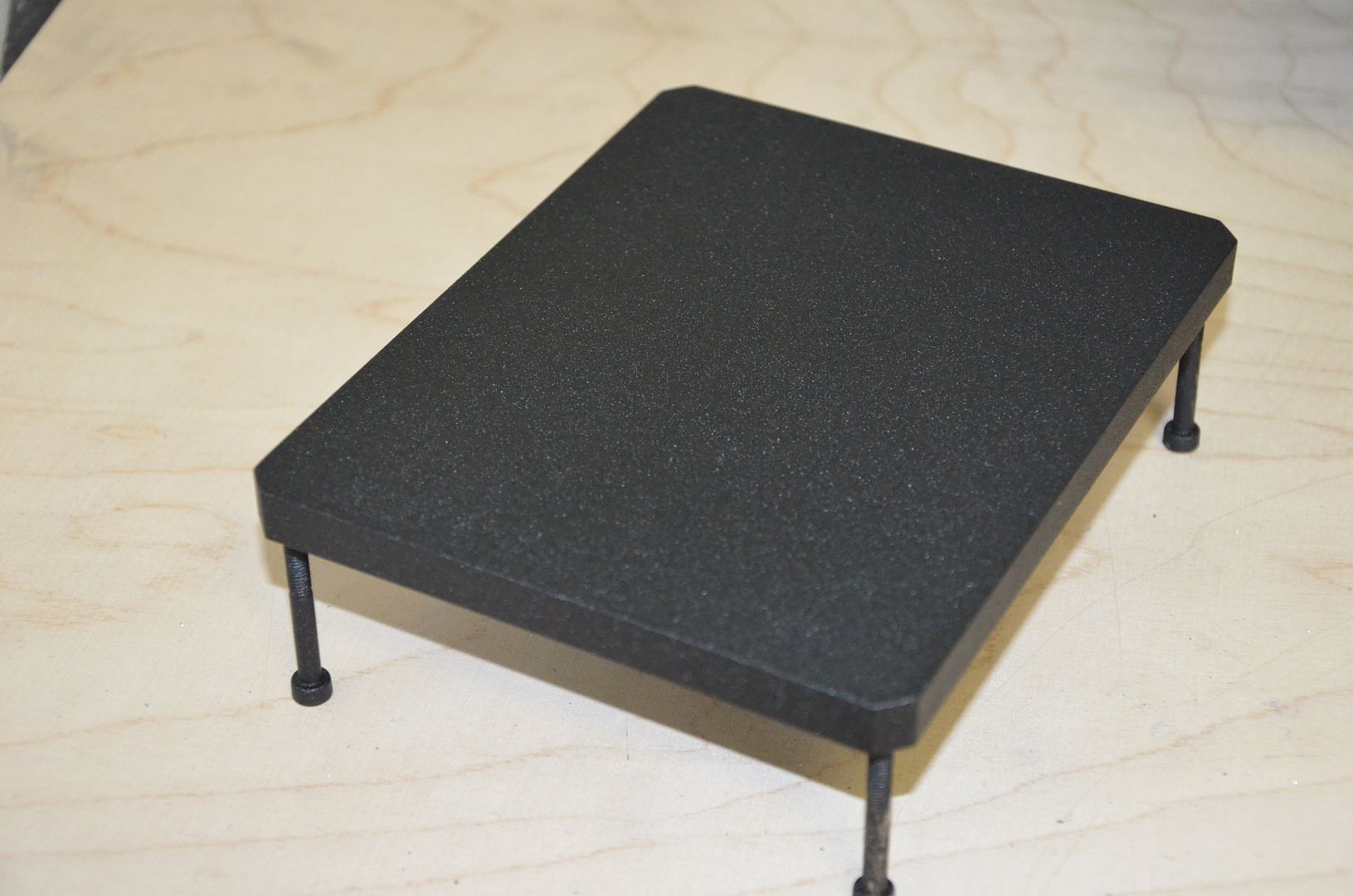

200x200x20mm piece of aluminum cut with a circular saw, worked a lot better than i thought it would.

As i recently finished upgrading my homebuilt CNC mill/router i thought i would put it to the test during this build

The Mill

Took me a while with the electronics since im no electrician and don't have a lot of skills with it, luckily no smoke

A bit of roughing with a 6mm endmill

More pictures soon as i have gotten a bit further than this.

Hope you like it and please drop a comment