trawetSluaP

Member

Hi all.

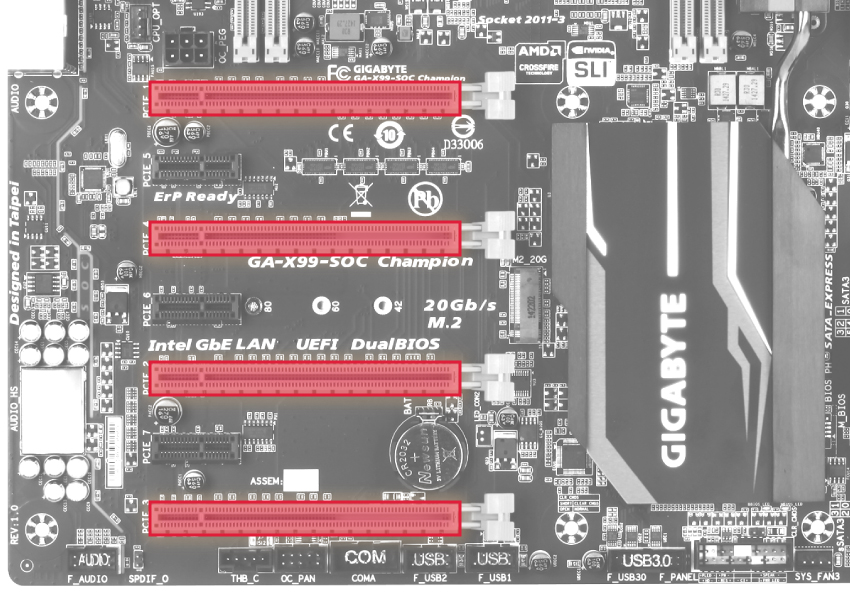

I have a Rog Rampage 6 Extreme and current have two GPUs connected - one in slot 1 and another in slot 5 (although it's only the 4th down as where slot 2 would be is a space.

They are spaced like this this to show of as much of the mobo as possible and they are the two x16 slots.

I've been having issues getting the soft tubing between the 2 cut to length so the cards are both exactly horizontal and it's quite frustrating (for me at least!).

I've considered purchasing one of EKs scalar blocks, however, it would appear they do not make a 5 slot block.

The EK-Scalar Dual 4-slot advice says it is suitable for blocks 81mm apart and having measured mine this is the distance between the two blocks (measure between the top of each block as they have back plates.

Am I wrong in thinking this would be suitable? If no block is compatible do you guys have any tips for soft tubing to get the exact lengths required?

Thanks,

Paul

I have a Rog Rampage 6 Extreme and current have two GPUs connected - one in slot 1 and another in slot 5 (although it's only the 4th down as where slot 2 would be is a space.

They are spaced like this this to show of as much of the mobo as possible and they are the two x16 slots.

I've been having issues getting the soft tubing between the 2 cut to length so the cards are both exactly horizontal and it's quite frustrating (for me at least!).

I've considered purchasing one of EKs scalar blocks, however, it would appear they do not make a 5 slot block.

The EK-Scalar Dual 4-slot advice says it is suitable for blocks 81mm apart and having measured mine this is the distance between the two blocks (measure between the top of each block as they have back plates.

Am I wrong in thinking this would be suitable? If no block is compatible do you guys have any tips for soft tubing to get the exact lengths required?

Thanks,

Paul