Blade Runner

New member

Having moved my hardware from my Ethnoo case to my STH10 I had an empty nearly new case. My daughter needed a proper PC to have set up for her homework at her desk (She is really into minions, who isn't?) so the plan is the following.

Hardware

The aforementioned Phanteks case - White

Asus Z170A motherboard

CPU - To be decided, one of the K type Skylakes but not urgent at the moment and hoping the prices come down a bit - I mean, the i7 Skylake is the same as a 5820K!

Gigabyte Radeon R9 280 Windforce (B grade at OCUK £105.00)

RAM - Again not urgent so waiting for DDR4 to drop a bit more in price.

OS Drive Corsair Neutron GTX 240GB

HDD WD 1TB

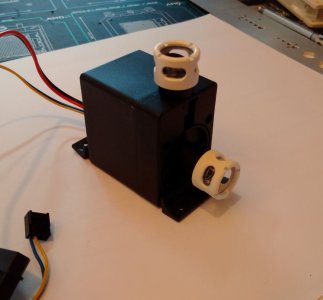

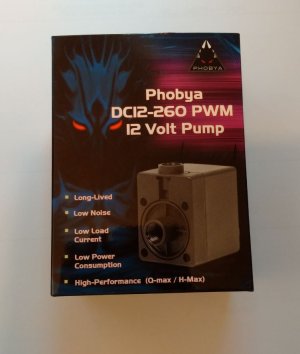

Watercooling

Alphacool 480 ST45 Push pull

Alphacool 280 ST60 Push pull

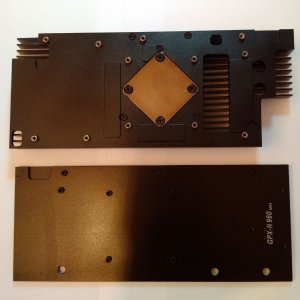

Alphacool NexXxos GPX - ATI R280 M02 Waterblock

Alphacool CPU and RAM Blocks

Alphacool Cape Corp Bullseye reservoir

Monsoon Hardline 16mm pipes and free centre fittings

Lighting

Aqua Computer Farbwerk USB Aquabus LED controller

General

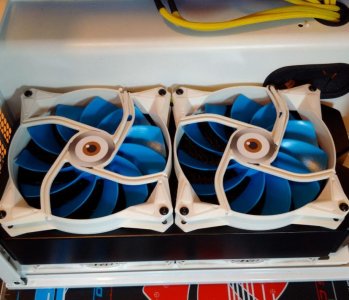

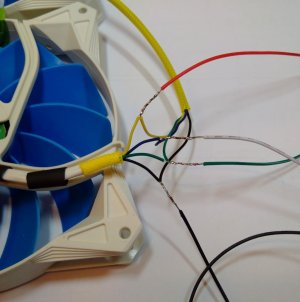

Fans are what I had on the old build, Phanteks and Enermax. I am having to buy 4 120 fans for the 480 rad, Silverstones with most wired back to the excellent Phanteks Fan Hub.

Minion theme - lots of yellow with black and blue highlights.

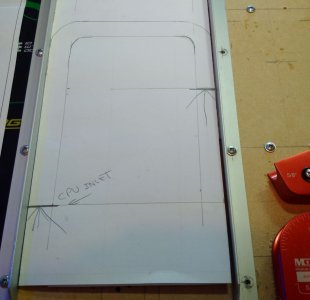

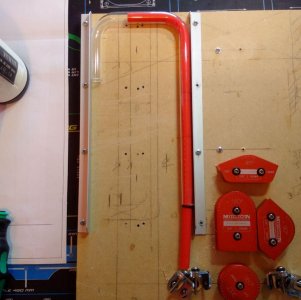

I have made a start on the pull fans for the 480 rad, these are 140s which were left over from the old build. They wont line up with the 480 rad so they will be fixed with 3M tape in the top of the case in the locations as shown.

ETA:-

Got the 24 pin cable made up and sleeved this evening, its yellow and blue.

Hardware

The aforementioned Phanteks case - White

Asus Z170A motherboard

CPU - To be decided, one of the K type Skylakes but not urgent at the moment and hoping the prices come down a bit - I mean, the i7 Skylake is the same as a 5820K!

Gigabyte Radeon R9 280 Windforce (B grade at OCUK £105.00)

RAM - Again not urgent so waiting for DDR4 to drop a bit more in price.

OS Drive Corsair Neutron GTX 240GB

HDD WD 1TB

Watercooling

Alphacool 480 ST45 Push pull

Alphacool 280 ST60 Push pull

Alphacool NexXxos GPX - ATI R280 M02 Waterblock

Alphacool CPU and RAM Blocks

Alphacool Cape Corp Bullseye reservoir

Monsoon Hardline 16mm pipes and free centre fittings

Lighting

Aqua Computer Farbwerk USB Aquabus LED controller

General

Fans are what I had on the old build, Phanteks and Enermax. I am having to buy 4 120 fans for the 480 rad, Silverstones with most wired back to the excellent Phanteks Fan Hub.

Minion theme - lots of yellow with black and blue highlights.

I have made a start on the pull fans for the 480 rad, these are 140s which were left over from the old build. They wont line up with the 480 rad so they will be fixed with 3M tape in the top of the case in the locations as shown.

ETA:-

Got the 24 pin cable made up and sleeved this evening, its yellow and blue.

Attachments

-

Dave.JPG95.2 KB · Views: 95

Dave.JPG95.2 KB · Views: 95 -

PhanteksHub.JPG80.5 KB · Views: 103

PhanteksHub.JPG80.5 KB · Views: 103 -

3FansTrialFit.JPG75.7 KB · Views: 91

3FansTrialFit.JPG75.7 KB · Views: 91 -

PhantekFan.jpg87.8 KB · Views: 87

PhantekFan.jpg87.8 KB · Views: 87 -

MotherboardTrialFit.jpg91.5 KB · Views: 90

MotherboardTrialFit.jpg91.5 KB · Views: 90 -

Motherboard_1.jpg91.1 KB · Views: 82

Motherboard_1.jpg91.1 KB · Views: 82 -

MotherboardBoxedGoodies.jpg83.2 KB · Views: 91

MotherboardBoxedGoodies.jpg83.2 KB · Views: 91 -

MotherboardBoxed.jpg85.2 KB · Views: 88

MotherboardBoxed.jpg85.2 KB · Views: 88 -

DaveStripped.jpg86.2 KB · Views: 91

DaveStripped.jpg86.2 KB · Views: 91 -

24PinSleeved.jpg81.1 KB · Views: 85

24PinSleeved.jpg81.1 KB · Views: 85 -

24PinSleevedRearView.JPG83.4 KB · Views: 90

24PinSleevedRearView.JPG83.4 KB · Views: 90

Last edited: