You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

**Black Ice** - The rescue/build log

- Thread starter w3bbo

- Start date

name='Jim' said:Wow mate that's looking like a totally new case now. You did it proud.

....so, when can you ship it back to me?

LOL - Indian giver!

name='Brooksie' said:Looking awesome webbo

Cheers m8. I just finished the tubing off and bleeding the loops now. Must admit I'm liking the black theme.

Ok, here's a shot of the *&!? up buy EK. I was honestly so peeved about this coz the whole kitchen was littered with PC components (much to the missus dismay) as I set about making the build all to be held up by one screw hole :

Still this little baby made me smile again:

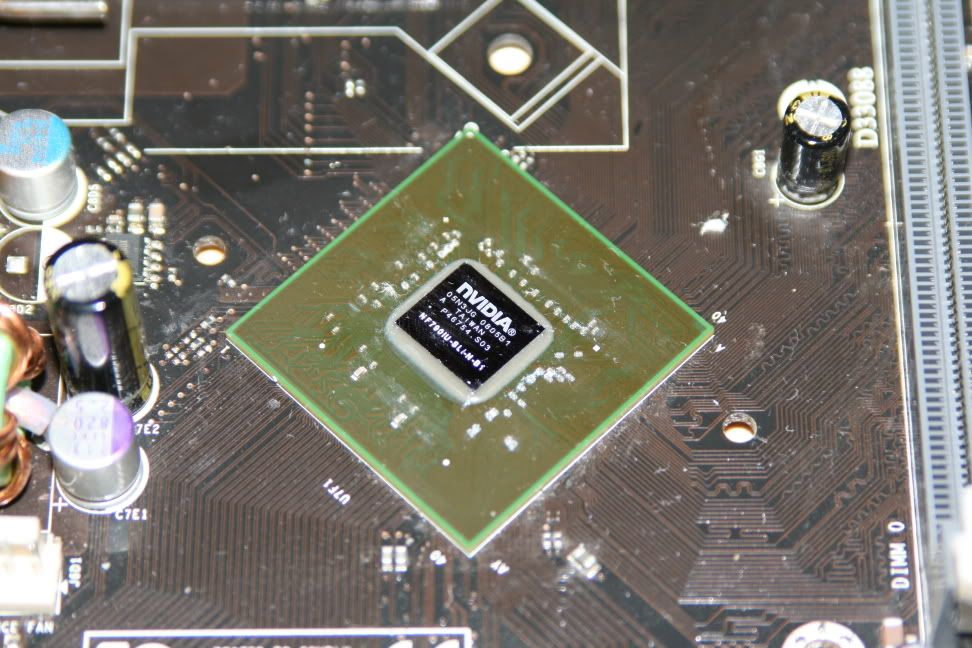

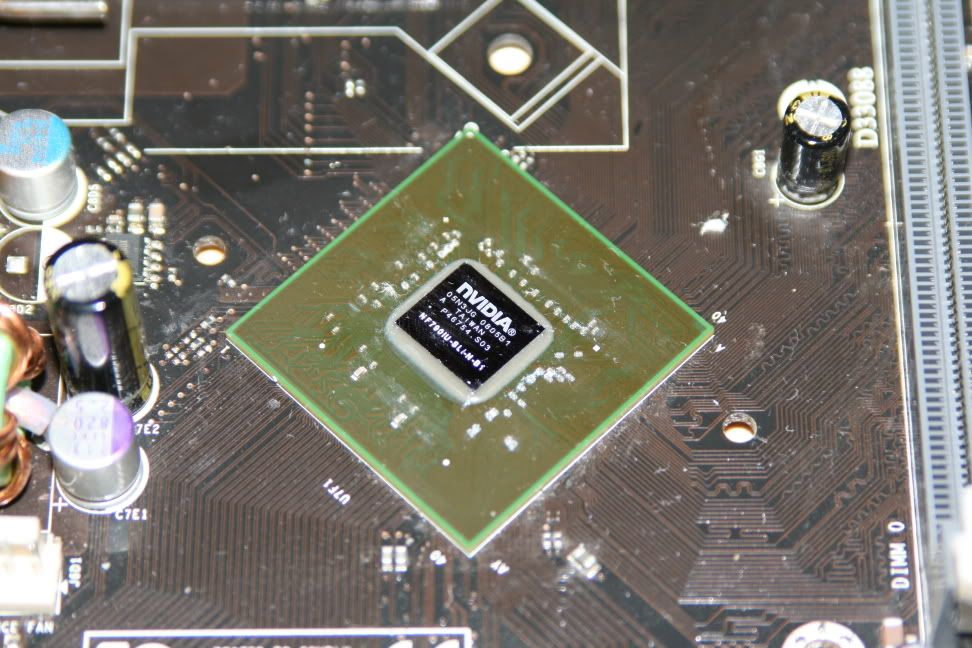

I don't think I'll be lapping this one tbh!

I took the opportunity to strip the 790i of its heatsinks in preparation of another SB/VGA block arriving:

Still this little baby made me smile again:

I don't think I'll be lapping this one tbh!

I took the opportunity to strip the 790i of its heatsinks in preparation of another SB/VGA block arriving:

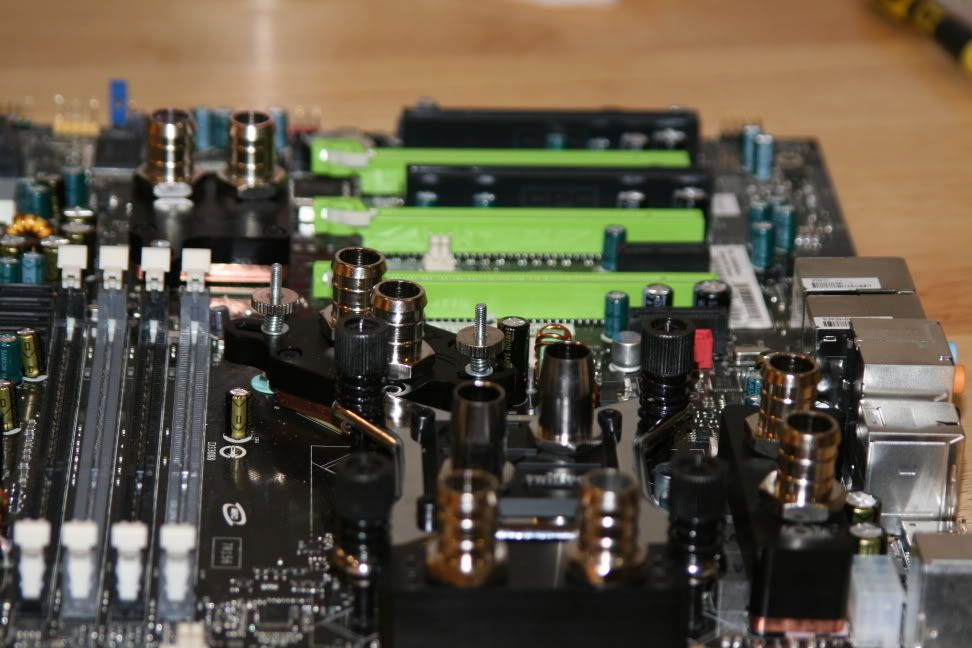

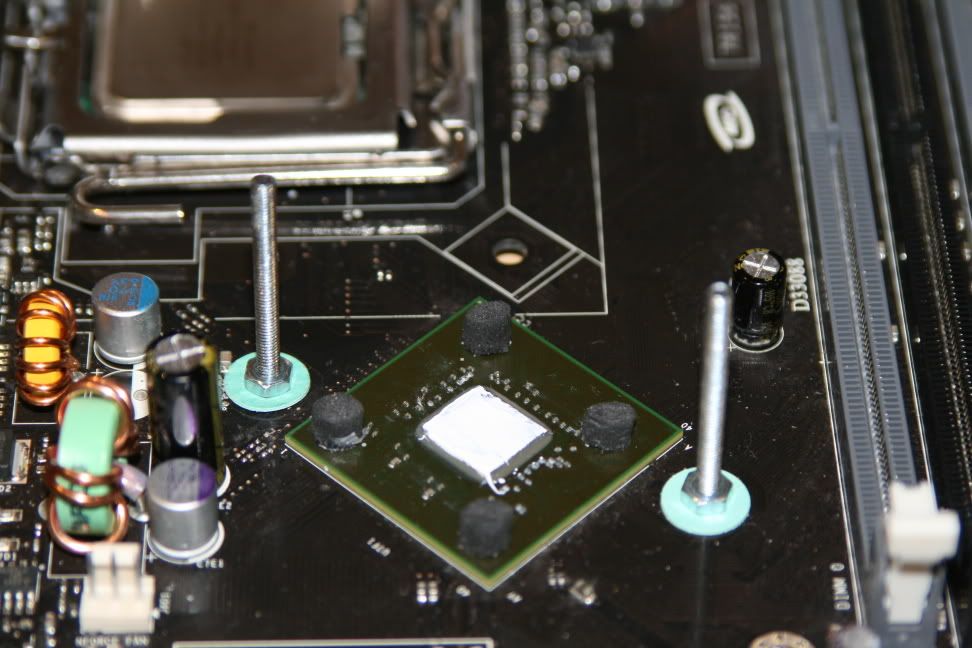

Now the drilled chipset block is here it was time to set to work on the motherboard:

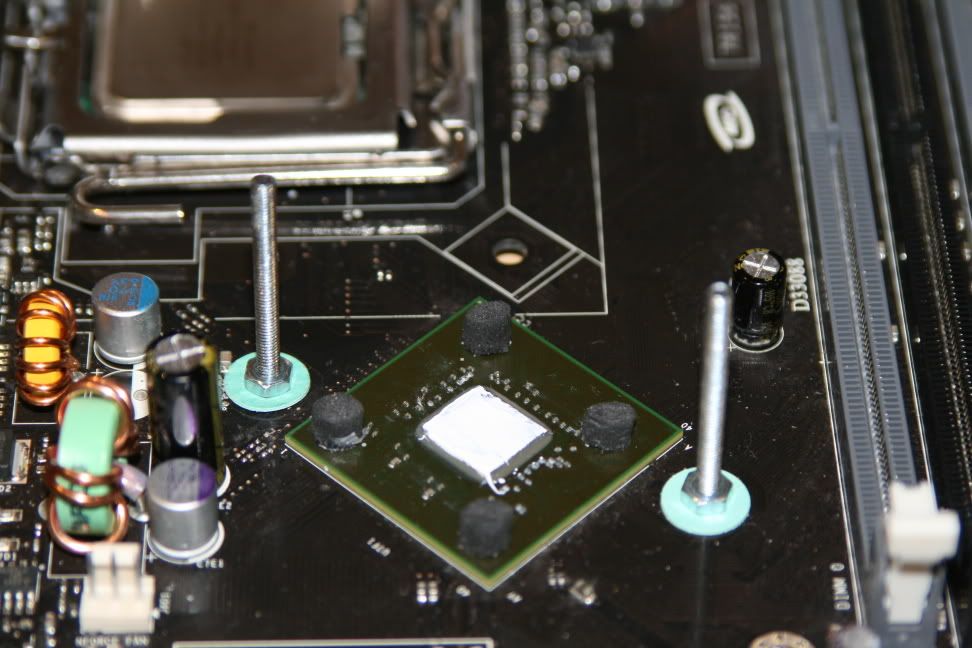

One thing I should point out at this stage is be VERY carefull with exposed cores as the can crack/nibble very easily if you don't get a good mount. It is also a good idea not to use conductive TIM on the chipsets as it can bleed on the surrounding capacitors shorting them out - arctic ceramique is my paste of choice for chipsets/GPU's. To prevent chipset 'wobble' when setting the blocks I used the little screw hole innards from the PA 120.3 neoprene gaskets as 'stabilizers' while screwing the blocks down which work really well:

God only knows how I'm gonna tube this lot up:

One thing I should point out at this stage is be VERY carefull with exposed cores as the can crack/nibble very easily if you don't get a good mount. It is also a good idea not to use conductive TIM on the chipsets as it can bleed on the surrounding capacitors shorting them out - arctic ceramique is my paste of choice for chipsets/GPU's. To prevent chipset 'wobble' when setting the blocks I used the little screw hole innards from the PA 120.3 neoprene gaskets as 'stabilizers' while screwing the blocks down which work really well:

God only knows how I'm gonna tube this lot up:

I needed to mount the pump as far away from the business end of the PA 120.3 to allow for tube curvature (I hate elbows) so I drilled a couple of holes then mounted the pump (DDC Ultra 18w XSPC top) with some anti vibration mounts:

I also put some blowhole trim edging around the pre cut holes to protect the tubing/cables:

Time for a quick measure up:

I also put some blowhole trim edging around the pre cut holes to protect the tubing/cables:

Time for a quick measure up:

Heres are few close-ups. I attached the 7/16ths XSPC black tubing to the barbs by first heating up the ends with boiling water so the tubing expands and becomes more flexible, attached to the blocks with an additional tie wrap and allowed the hot tubing to shrink fit onto the barbs while cooling to provide a watertight seal.

FarFarAway

New member

Nice mate, looking pretty sweet so far

Similar threads

- Replies

- 40

- Views

- 7K

- Replies

- 81

- Views

- 31K