Hello All

So, im new here this will be my first of hopefully many project logs,

in the first few posts ile outline the project and whati hope to end up with

Including my inspiration, how im going to get the job done (were talking a low enough budget to make a victorian family cringe)

And hopefully gather some interest for tips, help and some much needed support

I have a background in design and a lot of plastic scratch building from an addiction to 40k in my youth. As i lack a lot of the serious tools i will be coming up with some interesting ways round common problems

By the end of this i shall be hence forth known as "Dremel Boy" or if the cutting wheel slips "The 9 finger Noob"

So watch this space for what could be either an epic tryumph or epic fail... but hell either way should be interesting

First up some of the sources or inspiration, I suspect most can have a good guess from the project name

The good Old USS Sulaco, Marine carrier ship from Aliens

The Atmosphere processors may best reflect the feel, its heavy industry with big lines and chunky details

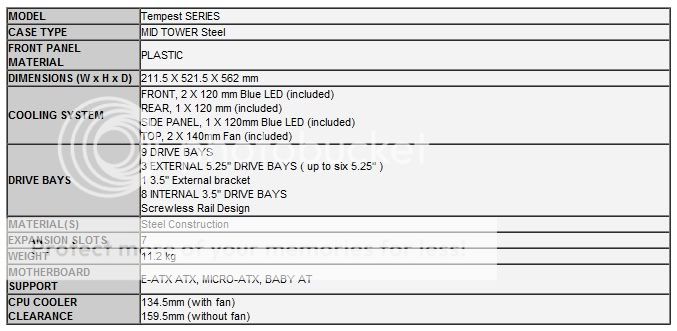

The case i am going to build on to is the NZXT Tempest EVO

Chunky Styling is allready a feature so it should be a superb platform to build on to

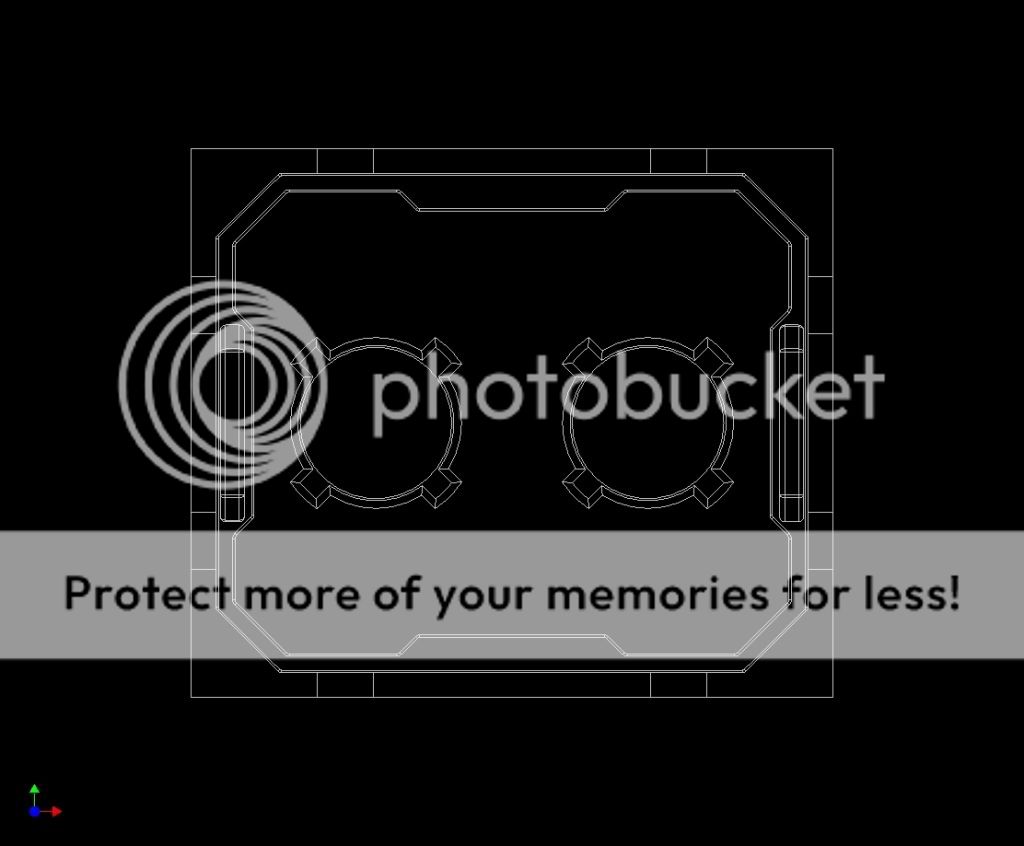

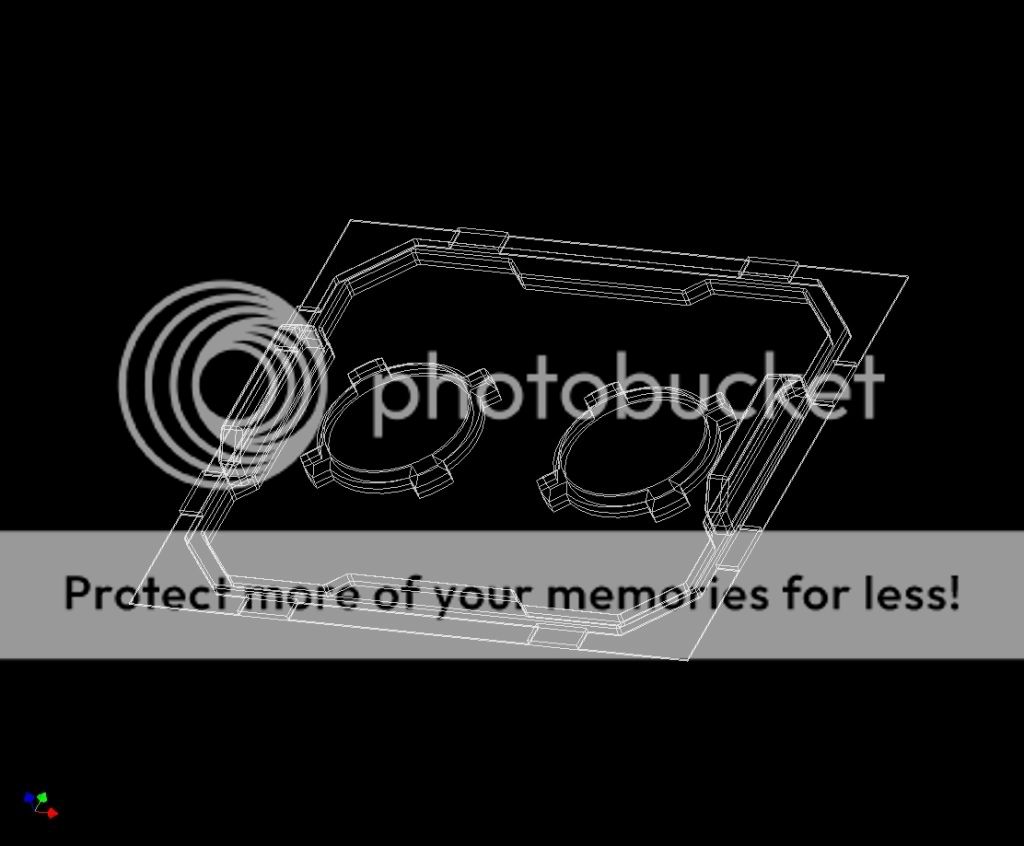

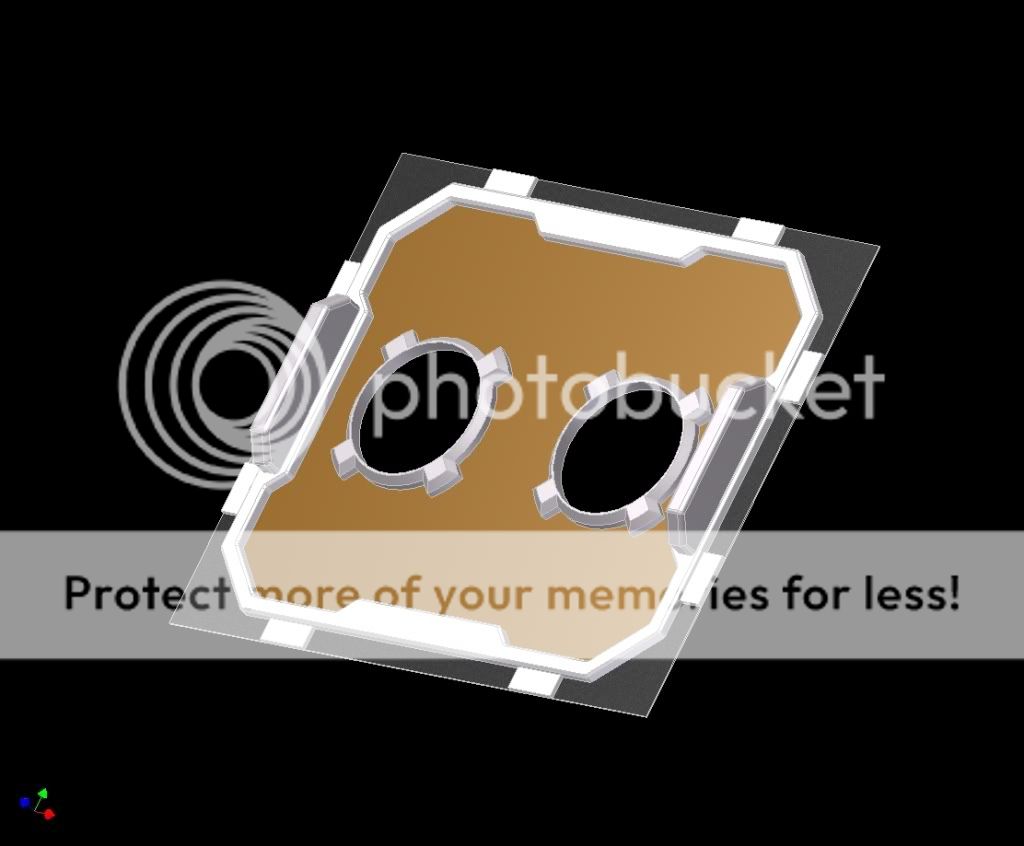

So were going with chunky industrial lines and a plated metal look to it, fan grills currently in design phase (OMG there huge) pics soon

SO why choose an NZXT Tempest evo?

Well lets look at its attributes

For a midtower this is huge.. and that's with a capital HU!

Steel Chassis, sire its not light but it sure as hell can take punishment and support some seriously heavy gear

And of course every ones concern.... cooling... although it has none of the trappings of 20mm fans it sports plenty in the 120mm to 140mm range. for me (A die hard air cooler)

it is perfect, but also sports 5 water-cooling grommets

Did i mention the case was big???

And on a final note... the case is big lol

Side on

Large tinted window and 120m fan with filter. A slight departure from most windows as it is mounted outside the case sitting proud of the side panel, it really helps to keel the case symetrical whilst also gaining a slight amount of extra clearance for the larger aircoolers out there

Inside

Well we are back to "ITS HUGE" no more bleeding fingers from case edges for me, i can in stall my rig in this and use it as a spare room for guests, its clutter free and the HDD racks are tool less and can be removed completly for GFX card space or for controlers to be hidden away behind the front support

Top

Recessed ports prevent them getting kicked or knocked... we all know the pain of hearing a crunch leaning over our pc and viewing the horror of a USB plus pointing 45deg out of the port, well break your ports no longer... and the area infrobt makes a handy dandy place to keep memory cards (well for me anyway)

It has great strong lines and a sharp clean shape, its huge panels leave plenty of space to mod in to/ on to/ over or through, its such a huge case with so many possabilities offered my its strong frame and sheer size that it was a huge headache picking a theme to use

I have been an NZXT fan for years, right back to the LEXA, and we are talking pre blackline edition

So without further boring you all to death (condolences to those who died of bordom reading)

Project Sulaco............