WYP

News Guru

Japanese Publication PC Watch has delidded Skylake, revealing a tiny CPU die and improving thermals dramatically.

Read more on Delidding Intel Skylake.

Read more on Delidding Intel Skylake.

WOW

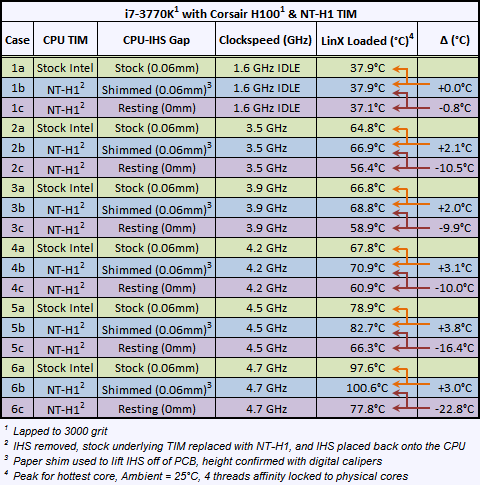

those temps with the coolaboratory stuff!!!!!

However I've been wondering, why doesn't intel use a better TIM on the die? Ok silicon lottery is silicon lottery but Intel can improve the TIM so everyone gets lower temps, they could partner up with coolaboratory and use that stuff for the i7s

Unless they plan doing something similar with the 1150 Haswels and Devils Canyon....

Seriously no excuse when the difference is 20*c, intel wont really be all that bothered as this only affects a minority of their customers.

could tolerances be an issue? Coolab stuff spreads properly thin, meaning you couldn't add as much 'glue' to the IHS outer rim. Perhaps using thicker, crappier stuff is literally just a way to physically fill the gap

I miss the liddless cpu's of the Athlon days

WOW

those temps with the coolaboratory stuff!!!!!

Unless they plan doing something similar with the 1150 Haswels and Devils Canyon....

What if they did this intentionally so that they could release skylake "Angels Canyon" in a years time? Dun dun dunnnnnnnnnnnnnn

could tolerances be an issue? Coolab stuff spreads properly thin, meaning you couldn't add as much 'glue' to the IHS outer rim. Perhaps using thicker, crappier stuff is literally just a way to physically fill the gap

I miss the liddless cpu's of the Athlon days

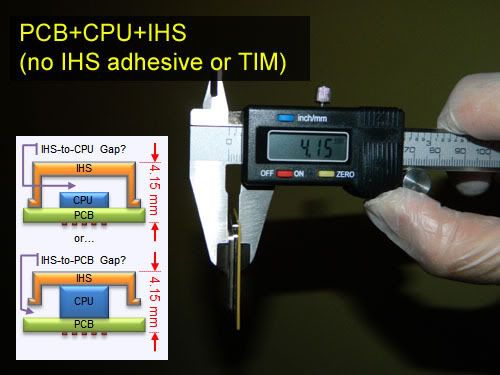

Yeah I mentioned this in my post before, the gap was measured on ivy bridge CPUs to be quite large (can't remember off the top of my head exactly) and removing the 'glue' reduced it to almost nothing.