My Raystorm kit, EX 240 & D5 pump came yesterday, and I've been fooling around with it since.

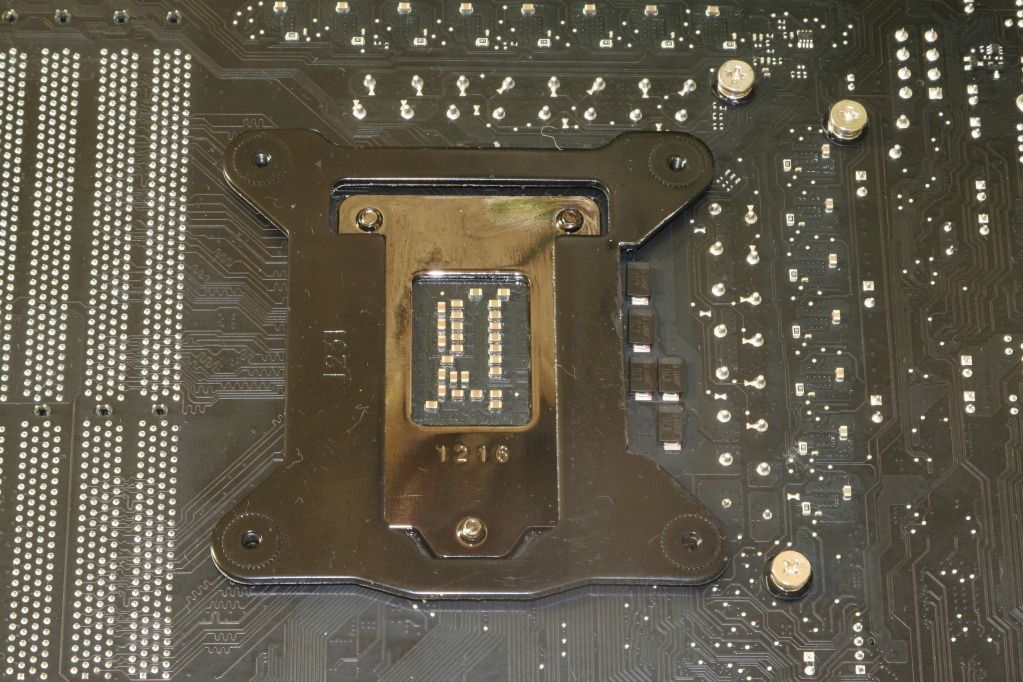

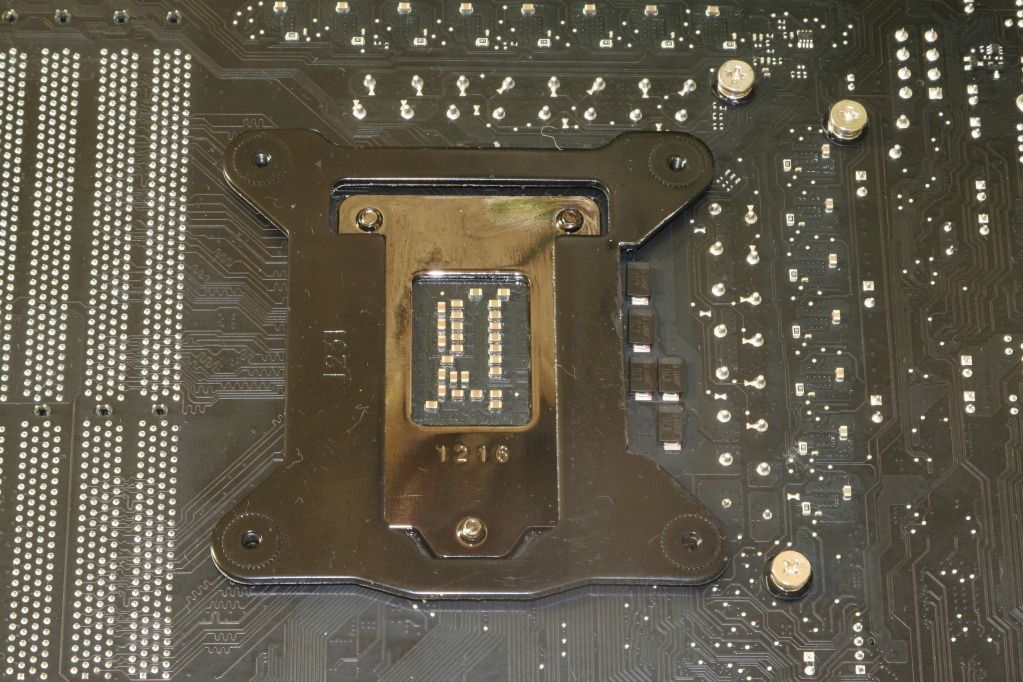

I had to relieve that 1155/1156 backplate in one area to provide clearance for some components on the MSi Z77 MPower board. The entire kit is very nice, EXCEPT the mounting screws for the water block are too short. The block has to tipped to even get the screws started. To my way of thinking, the screws should bottom out on the backplate easily, allowing the block to sit flat on the processor, and then the secondary nuts screwed down to apply the desired spring pressure. As it is now, it's a bit of a pain to mount.

Did anyone else notice this issue?

BTW, I am using the aluminum mounting flange because I have seen so many photos of plexi flanges that are bent from the heavy pressure.

Any thoughts?

I had to relieve that 1155/1156 backplate in one area to provide clearance for some components on the MSi Z77 MPower board. The entire kit is very nice, EXCEPT the mounting screws for the water block are too short. The block has to tipped to even get the screws started. To my way of thinking, the screws should bottom out on the backplate easily, allowing the block to sit flat on the processor, and then the secondary nuts screwed down to apply the desired spring pressure. As it is now, it's a bit of a pain to mount.

Did anyone else notice this issue?

BTW, I am using the aluminum mounting flange because I have seen so many photos of plexi flanges that are bent from the heavy pressure.

Any thoughts?

Last edited: