rapidman17

New member

Ok, this review is on some standard, ubranded thermal paste that Jim asked me to do a review on. Basically, as this is my first review, I am looking for crticism and suggestions for improvement so that I can perfect my reviewing style. I know it is a boring item but all feeback is greatly appreciated. One thing I noted already is that the graphs are quite tacky and there is a touch of noise in the first photo; these things are already being worked upon.

Thanks in advance,

rapidman17

Introduction

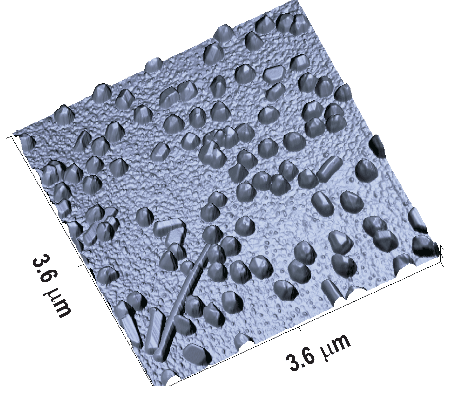

Thermal paste, or more technically, ‘Thermal Interface Material’ (TIM), has historically been one of the more overlooked aspects of system building. It is only recently, due to the rises in CPU speeds, and therefore huge increases in heat generated, that the importance of this viscous substance has been recognised. Thermal paste aims to solve a problem found only on a microscopic level; to the naked eye, the contact between the mirror-finished heatsink and the smooth surface of a processor may seem even, but in reality, looks something more like this:

The gaps you see are pockets of air which, due to its nature as a thermal insulator, can lead to very poor heat conductivity causing a rise in core temperature. To the overclocker, even small rises in temperature will reduce the maximum clock speed, so this unevenness needs to be eliminated. The paste therefore is a thermal conductor -at least 30 times more efficient than air- which tries to replace these gaps and ensure maximum heat conduction, resulting in lower temperatures and greater longevity of the processor.

Thermal paste has evolved rapidly in recent years, and the choice available to the enthusiast has increased dramatically over the last few years as companies try and claim a stake of this growing specialist market. From the well known names including OCZ and Coolermaster, to specialists such as Arctic Cooling and Shin-Etsu, they all offer a variety of thermal pastes that claim to offer the ultimate cooling performance.

However, today I will be reviewing an unbranded thermal paste that does not assert this title, rather has been designed to ‘get the job done’ by providing adequate cooling for the average PC. It is this TIM that you will find in the millions of computers shipped every year; cheap and cheerful it has been used for the past decades by system builders who aren’t concerned with minimum possible temperatures and just need to make sure something is filling those gaps.

Anyhow, let’s take a closer look at today’s sample grease…

The Product

The paste does not come in any meaningful packaging apart from a see-through plastic housing. As a result there is no information or details about the paste, possibly because the manufacturers assume system builders do not require such pleasantries, and also to cut production costs.

Housed in a standard plastic syringe, the TIM itself is white in colour indicating that it is ceramic based and suspended in a gelatinous silicone compound. I’m sure no-one wants me to detail the mechanisms of a syringe; clearly it makes application of the grease easier and fairly controllable.

Applied on the processor we see it has a fairly thick consistency and after 48 hours has held together well. However, it is less viscous than any metal based paste so there shouldn’t be any problems of it drying out. Removal of the stuff should also be easy in the event you need to reapply; some isopropyl alcohol (rubbing alcohol) or ArctiClean will do nicely.

Normally I would list the specification of the product as provided by the manufacturer, but unfortunately this particular thermal paste is unbranded so is unavailable. However, as manufacturers tend to stick to similar specifications for this kind of product , I thought it would be useful to provide a description from one large manufacturer of ceramic based paste:

Before we see how the paste performs, let’s take a quick look at the test system and testing methodology….

Testing

The testbed for this review comprises of the following:

Intel Pentium D 945 @ 3.40ghz (standard clock settings)

Intel reference HSF

Foxconn 662 7MB Motherboard

2GB PC2-6400 DDR2 RAM @ 5-5-15-15 1.8V

Nvidia GeForce 8400 GS

Seagate 7200RPM HDD

Windows XP (Build 2600) Service Pack 3

Having fairly low spec components and a rather toasty CPU, combined with the reference heatsink, should allow maximum stress on the thermal paste.

Measuring the temperature will be done using Speedfan 4.38. This is because it allows us to calibrate the temperature sensors to a lesser margin of error, and also provides Tcase (Thermal Diode located within the CPU die between the Cores) and Tjunction (Digital Thermal Sensors located within each Core) temperature readings. As a result we should find the data gives a more accurate view of how well the paste performs.

In terms of application of the paste on the processor, I will be opting for the ‘blob-in-the-middle’ technique seen above. It is the generally more preferred method as it reduces the risk of using too much paste.

Spreading the paste yourself (above) can also result in an uneven finish. It is easier to allow the pressure of the heatsink to disperse the thermal paste as it will naturally fill the gaps of air, thus resulting in a more even contact.

To give a comparison of the performance of this paste, I will be testing it against OCZ Freeze which is a favourite among many enthusiasts. Each sample will be applied 3 times and averaged to give a reliable result. Idle temperatures will be taken after thirty minutes of the paste being applied, and load temperatures after fifteen minutes of torture tests using 2 instances of Prime95 25.9 for the 2 cores. Ambient temperature during testing was averaged at 22.8 °C.

Right, onto the results then…

Results

Observations

At stock settings we see that the ceramic based paste does a good enough job keeping up with the OCZ Freeze when the computer is at idle. However, at load we begin to see significant differences; it is ‘out cooled’ by 5.3 °C at load and this is only on stock settings. However, at 60.5°C it is still well within Intel guideline temperatures, so does not present much of a problem.

Overclocking to 4Ghz stable was a simple enough affair, but this is where the ceramic based grease really struggled. Hitting the 70°C mark is moving into dangerous territory in my opinion and at 67.3°C during load, I was waiting for my alarms to go blaring and the PC to shut down. By comparison, the OCZ Freeze did a good job keeping those temps down, a massive 6°C less than the ceramic based compound

Conclusion

Overall it is very hard to criticise this ceramic based paste as it does exactly what it was designed for. At standard clock settings it does perfectly well keeping core temps within guideline limits. Cheap and easy to apply, it is good enough for users with average PC’s who aren’t concerned with the highest clocks and lowest possible temperatures. Obviously, enthusiasts who are in fact looking to get the best performance from their setups will not be wanting to use this paste, instead should be opting for the specialist products from the likes of OCZ and Shin-Etsu.

Ceramic based thermal compound (also known as silicon based), like the one used today, is available for around £1-2 from any online retailer or local hardware shop. This amounts to fantastic value for money when compared to AS5 for example which retails around the £6.50 mark, thus making it ideal for the home user or system builder.

The Good

Cheap

Easy to apply & remove

The Mediocre

Packaging is almost non-existent

No instructions for use

The Bad

Not suitable if overclocking

Thanks in advance,

rapidman17

Introduction

Thermal paste, or more technically, ‘Thermal Interface Material’ (TIM), has historically been one of the more overlooked aspects of system building. It is only recently, due to the rises in CPU speeds, and therefore huge increases in heat generated, that the importance of this viscous substance has been recognised. Thermal paste aims to solve a problem found only on a microscopic level; to the naked eye, the contact between the mirror-finished heatsink and the smooth surface of a processor may seem even, but in reality, looks something more like this:

The gaps you see are pockets of air which, due to its nature as a thermal insulator, can lead to very poor heat conductivity causing a rise in core temperature. To the overclocker, even small rises in temperature will reduce the maximum clock speed, so this unevenness needs to be eliminated. The paste therefore is a thermal conductor -at least 30 times more efficient than air- which tries to replace these gaps and ensure maximum heat conduction, resulting in lower temperatures and greater longevity of the processor.

Thermal paste has evolved rapidly in recent years, and the choice available to the enthusiast has increased dramatically over the last few years as companies try and claim a stake of this growing specialist market. From the well known names including OCZ and Coolermaster, to specialists such as Arctic Cooling and Shin-Etsu, they all offer a variety of thermal pastes that claim to offer the ultimate cooling performance.

However, today I will be reviewing an unbranded thermal paste that does not assert this title, rather has been designed to ‘get the job done’ by providing adequate cooling for the average PC. It is this TIM that you will find in the millions of computers shipped every year; cheap and cheerful it has been used for the past decades by system builders who aren’t concerned with minimum possible temperatures and just need to make sure something is filling those gaps.

Anyhow, let’s take a closer look at today’s sample grease…

The Product

The paste does not come in any meaningful packaging apart from a see-through plastic housing. As a result there is no information or details about the paste, possibly because the manufacturers assume system builders do not require such pleasantries, and also to cut production costs.

Housed in a standard plastic syringe, the TIM itself is white in colour indicating that it is ceramic based and suspended in a gelatinous silicone compound. I’m sure no-one wants me to detail the mechanisms of a syringe; clearly it makes application of the grease easier and fairly controllable.

Applied on the processor we see it has a fairly thick consistency and after 48 hours has held together well. However, it is less viscous than any metal based paste so there shouldn’t be any problems of it drying out. Removal of the stuff should also be easy in the event you need to reapply; some isopropyl alcohol (rubbing alcohol) or ArctiClean will do nicely.

Normally I would list the specification of the product as provided by the manufacturer, but unfortunately this particular thermal paste is unbranded so is unavailable. However, as manufacturers tend to stick to similar specifications for this kind of product , I thought it would be useful to provide a description from one large manufacturer of ceramic based paste:

Specifications

Thermal Conductivity: 1.729 W/m-K

ThermalImpedance:0.125C/W

Specific Gravity: 2.3

Evaporation: 0.001

Bleed: 0.05

Dielectric Constant: 5.1A

Operation Temp: -30 ~ 180C

Storage Temp: -50 ~ 240C

http://www.spirecoolers.com/

Note: these should not be taken as the correct specifications for this particular thermal paste, rather as a guidance of its probable properties.

Before we see how the paste performs, let’s take a quick look at the test system and testing methodology….

Testing

The testbed for this review comprises of the following:

Intel Pentium D 945 @ 3.40ghz (standard clock settings)

Intel reference HSF

Foxconn 662 7MB Motherboard

2GB PC2-6400 DDR2 RAM @ 5-5-15-15 1.8V

Nvidia GeForce 8400 GS

Seagate 7200RPM HDD

Windows XP (Build 2600) Service Pack 3

Having fairly low spec components and a rather toasty CPU, combined with the reference heatsink, should allow maximum stress on the thermal paste.

Measuring the temperature will be done using Speedfan 4.38. This is because it allows us to calibrate the temperature sensors to a lesser margin of error, and also provides Tcase (Thermal Diode located within the CPU die between the Cores) and Tjunction (Digital Thermal Sensors located within each Core) temperature readings. As a result we should find the data gives a more accurate view of how well the paste performs.

In terms of application of the paste on the processor, I will be opting for the ‘blob-in-the-middle’ technique seen above. It is the generally more preferred method as it reduces the risk of using too much paste.

Spreading the paste yourself (above) can also result in an uneven finish. It is easier to allow the pressure of the heatsink to disperse the thermal paste as it will naturally fill the gaps of air, thus resulting in a more even contact.

To give a comparison of the performance of this paste, I will be testing it against OCZ Freeze which is a favourite among many enthusiasts. Each sample will be applied 3 times and averaged to give a reliable result. Idle temperatures will be taken after thirty minutes of the paste being applied, and load temperatures after fifteen minutes of torture tests using 2 instances of Prime95 25.9 for the 2 cores. Ambient temperature during testing was averaged at 22.8 °C.

Right, onto the results then…

Results

Observations

At stock settings we see that the ceramic based paste does a good enough job keeping up with the OCZ Freeze when the computer is at idle. However, at load we begin to see significant differences; it is ‘out cooled’ by 5.3 °C at load and this is only on stock settings. However, at 60.5°C it is still well within Intel guideline temperatures, so does not present much of a problem.

Overclocking to 4Ghz stable was a simple enough affair, but this is where the ceramic based grease really struggled. Hitting the 70°C mark is moving into dangerous territory in my opinion and at 67.3°C during load, I was waiting for my alarms to go blaring and the PC to shut down. By comparison, the OCZ Freeze did a good job keeping those temps down, a massive 6°C less than the ceramic based compound

Conclusion

Overall it is very hard to criticise this ceramic based paste as it does exactly what it was designed for. At standard clock settings it does perfectly well keeping core temps within guideline limits. Cheap and easy to apply, it is good enough for users with average PC’s who aren’t concerned with the highest clocks and lowest possible temperatures. Obviously, enthusiasts who are in fact looking to get the best performance from their setups will not be wanting to use this paste, instead should be opting for the specialist products from the likes of OCZ and Shin-Etsu.

Ceramic based thermal compound (also known as silicon based), like the one used today, is available for around £1-2 from any online retailer or local hardware shop. This amounts to fantastic value for money when compared to AS5 for example which retails around the £6.50 mark, thus making it ideal for the home user or system builder.

The Good

Cheap

Easy to apply & remove

The Mediocre

Packaging is almost non-existent

No instructions for use

The Bad

Not suitable if overclocking