taylormadecomputers

New member

current specs

Dont have clue who made the server case ( but weighs a ton and is very limited for cable managment )

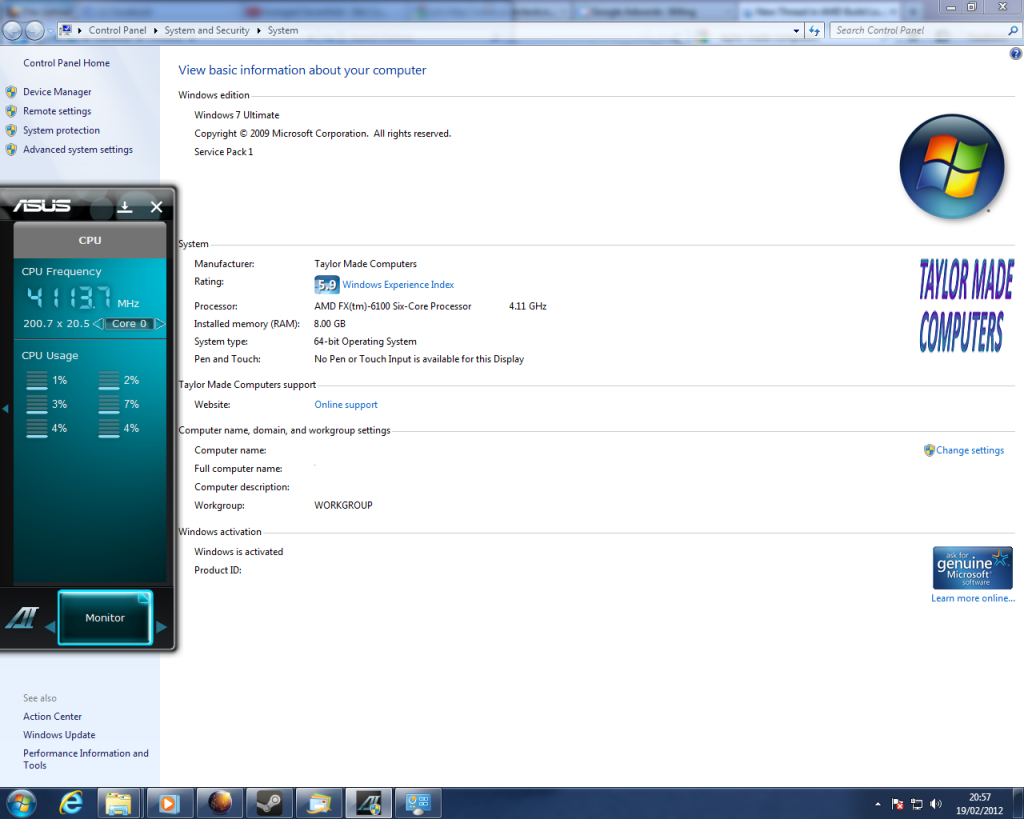

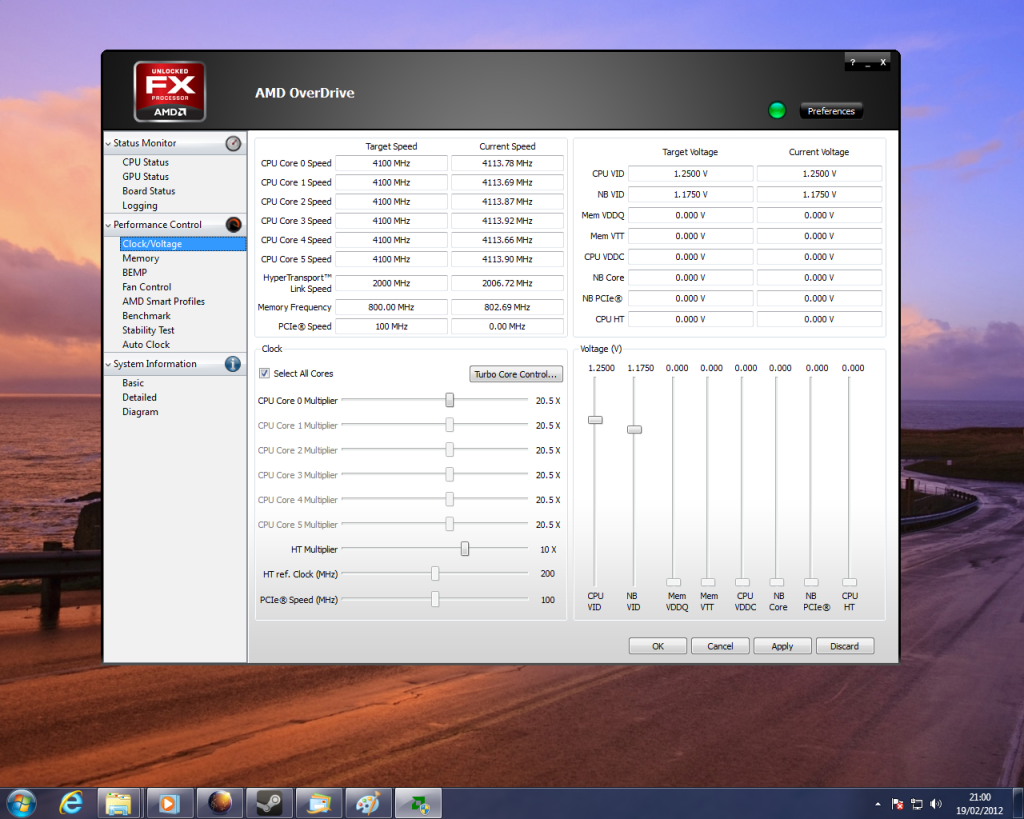

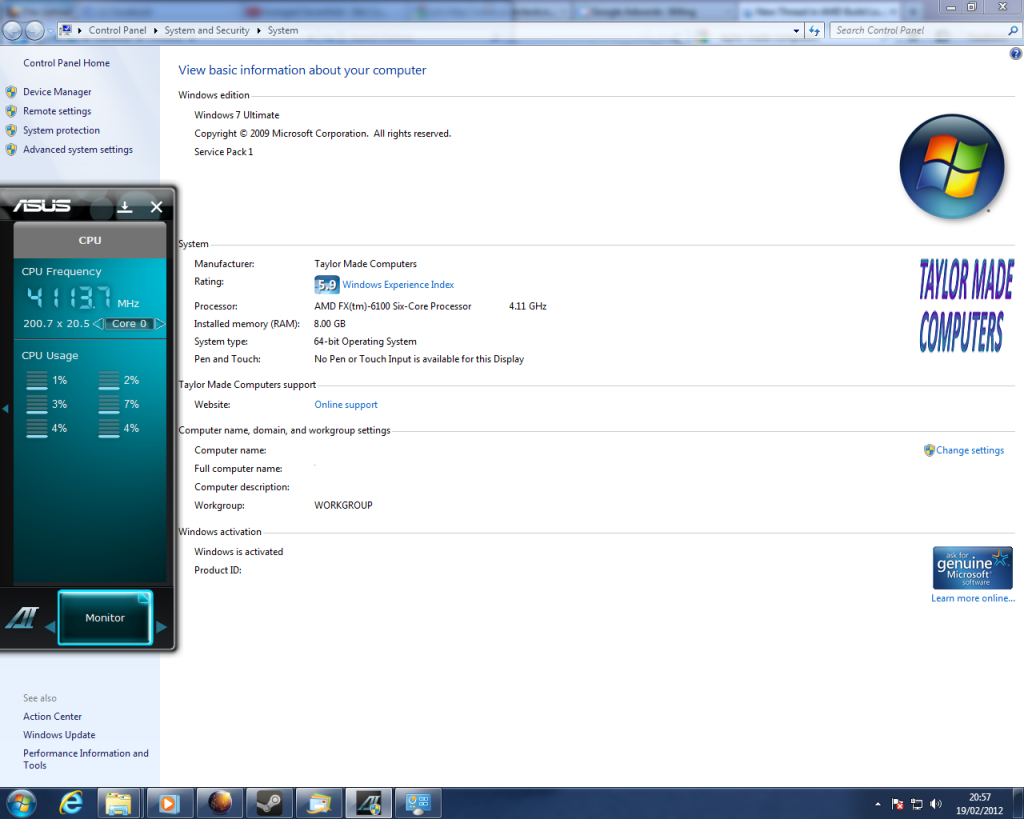

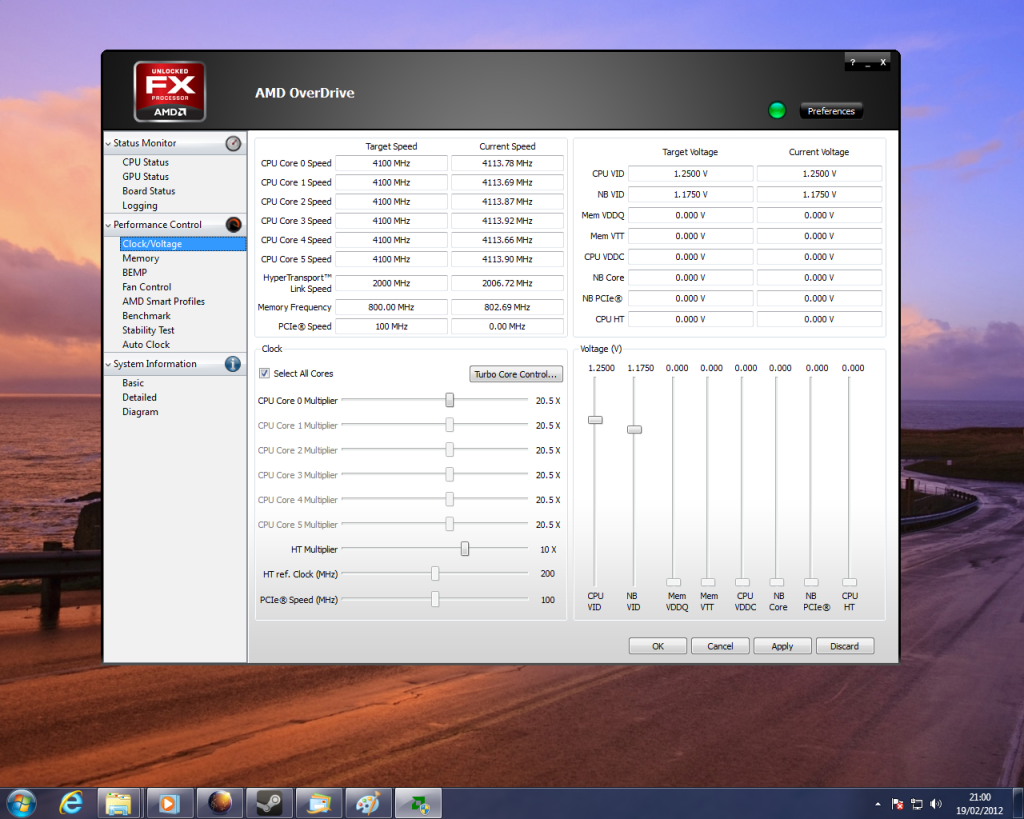

AMD FX 6100 currently overclocked to 4.1ghz ( currently limited by air cooler)

ASUS gtx 550 ti graphics card

8GB exceleram rippler sandy bridge series (overclocked)

ASUS m5a97 Mobo

cheap cpu cooling fan

arctic cooling 120mm fans

cheap tv card

OCZ 500W mod x stream pro modular

uv kit

1.5TB sata 2 mdt hard drive

planned additions soon to come

sabertooth 990fx mobo

custom H100 watr cooling install or dual 5.25 reservoir and pump setup

1 PNY 240gb SSD

Further 8GB excelram

how it all began

found a server case lying around my house must have been one i bought along time ago and never used back then it looked good now it looked abit plain. the tall silver and black one

Decided that i couldnt live with sutch a plain eye sore at the time and thought a temporary respray was in order.

cut the side panel to fit a window in, and accidently dropped my hammer on it so got a nice crack line over it luckily it was only a rough fitting as the panel needs finishing of and smothing over.

next i decided to attack my cable managment and try and work out where i wanted cables to go and how i wanted it to all look, so i went out and bought some cheap tacky hole saws and they did exactly what they said on the tin cuts imaginary sheet steel and chocolate fire guards. burnt out 4 bits in 10 seconds to a state of no teeth.

eventually after getting the tin snips out a flannel for the shear sweat of manual labour i managed to cut a round is hole got the cables through and everything tied up and hidden where i wanted it to be.

and at night

once i got everything in place and fitted up it was time to setup the bios the way i wanted it to get a decent overclock on a crappy am2+ cooler im not cheap i just like the uv red of this cooler until i put the h100 or custom water kit in.

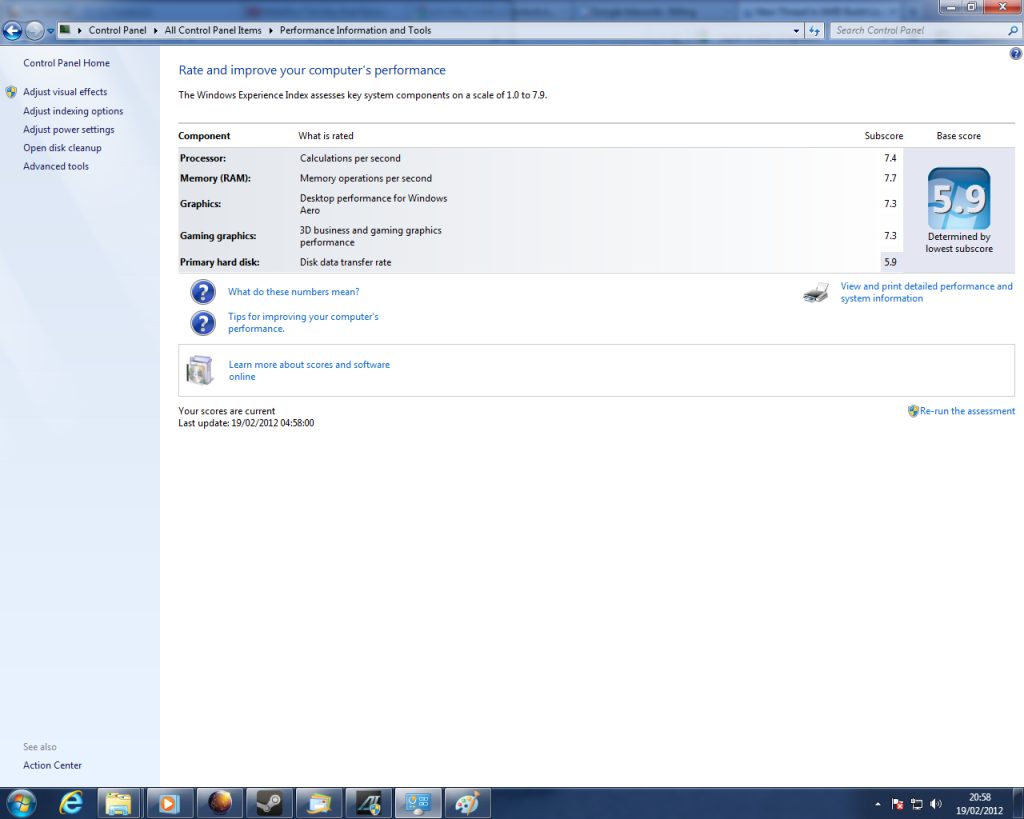

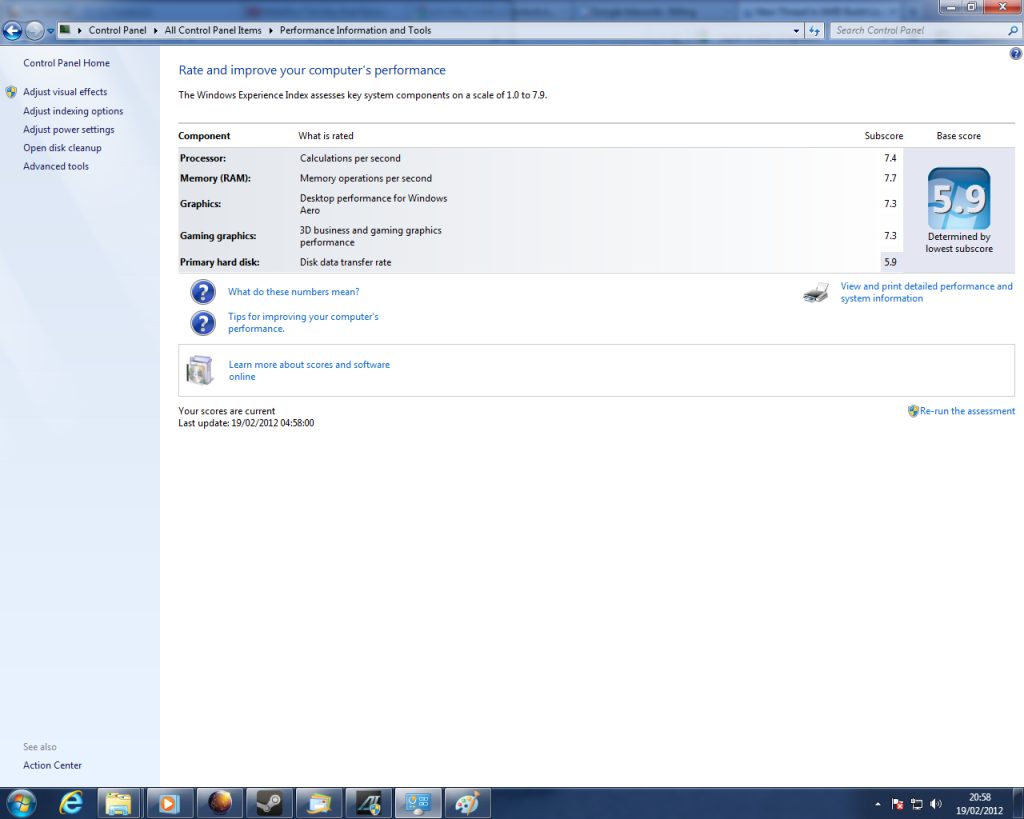

managed to get the ram to decent profile for what it is and windows agreed 7.7 score on windows BS for memory aint to shabby in my eyes.

have got some more work to do and then to get it all ripped back out to take the case to get propperly sprayed rattle can only work to a certain point.

if any one is interested i have some left over stock from asus couple of posters full wall size that are sat in my workshop doing nowt

also got a 2u server case and a 4u server case that i no longer use was tempted to do the 4u as a gaming rig project i think a clear top water cooling project case would be sweet. but havent got the time at the moment the server cases are in top pic i can send more if any one is interested.

Dont have clue who made the server case ( but weighs a ton and is very limited for cable managment )

AMD FX 6100 currently overclocked to 4.1ghz ( currently limited by air cooler)

ASUS gtx 550 ti graphics card

8GB exceleram rippler sandy bridge series (overclocked)

ASUS m5a97 Mobo

cheap cpu cooling fan

arctic cooling 120mm fans

cheap tv card

OCZ 500W mod x stream pro modular

uv kit

1.5TB sata 2 mdt hard drive

planned additions soon to come

sabertooth 990fx mobo

custom H100 watr cooling install or dual 5.25 reservoir and pump setup

1 PNY 240gb SSD

Further 8GB excelram

how it all began

found a server case lying around my house must have been one i bought along time ago and never used back then it looked good now it looked abit plain. the tall silver and black one

Decided that i couldnt live with sutch a plain eye sore at the time and thought a temporary respray was in order.

cut the side panel to fit a window in, and accidently dropped my hammer on it so got a nice crack line over it luckily it was only a rough fitting as the panel needs finishing of and smothing over.

next i decided to attack my cable managment and try and work out where i wanted cables to go and how i wanted it to all look, so i went out and bought some cheap tacky hole saws and they did exactly what they said on the tin cuts imaginary sheet steel and chocolate fire guards. burnt out 4 bits in 10 seconds to a state of no teeth.

eventually after getting the tin snips out a flannel for the shear sweat of manual labour i managed to cut a round is hole got the cables through and everything tied up and hidden where i wanted it to be.

and at night

once i got everything in place and fitted up it was time to setup the bios the way i wanted it to get a decent overclock on a crappy am2+ cooler im not cheap i just like the uv red of this cooler until i put the h100 or custom water kit in.

managed to get the ram to decent profile for what it is and windows agreed 7.7 score on windows BS for memory aint to shabby in my eyes.

have got some more work to do and then to get it all ripped back out to take the case to get propperly sprayed rattle can only work to a certain point.

if any one is interested i have some left over stock from asus couple of posters full wall size that are sat in my workshop doing nowt

also got a 2u server case and a 4u server case that i no longer use was tempted to do the 4u as a gaming rig project i think a clear top water cooling project case would be sweet. but havent got the time at the moment the server cases are in top pic i can send more if any one is interested.