Hello OC3D, I wanted to share with you all a project I have been working on for almost 2 years now.

It's not the newest hardware being that when I started Haswell had just come out and unfortunately (or fortunately depending how you look at it) simple life things have lengthened this project.

This should be a fairly quick log as all the work is almost done and I'm at the point where all that's needed is some slight detail work and final pictures. Which I hope to complete in a week or so. Not to mention last time I posted a build here it was only rig pictures instead of a log and I'd like to tell the whole story this time.

This is also the first time I have watercooled a PC and on top of that I decided to jump straight to acrylic tubing. Up until acrylic started becoming mainstream I was seriously turned off of watercooling simply because of aesthetics. When I saw builds using copper (BNEG) and then acrylic I knew a hardline system was something I would definitely be down for. lol

I'm going to start off with system specs/details and pictures. PLease forgive the first couple of pictures as they will get better.

Case...........................................Zalman GS1000

Motherboard...............................Gigabyte GA-Z77X-UP7

CPU............................................Intel I7-3770k

RAM............................................Corsair Dominator Platinum 2133mhz 16GB (4x4gb)

SSD's..........................................OCZ Vertex 4 128GB x2 in RAID 0 (OS+few games)

HDD............................................2TB Seagate 7200rpm (storage)

Power Supply..............................Cooler Master V1000 modular 1000watt

Graphics......................................Saphire R9 290 x2 (reference)

Sound..........................................Creative Sound Blaster Z

Now for the watercooling side of things I have chosen the componets that looks wise fit the look I was looking for. I am not really a brand loyalist and simply use what looks best to me. :thumb:

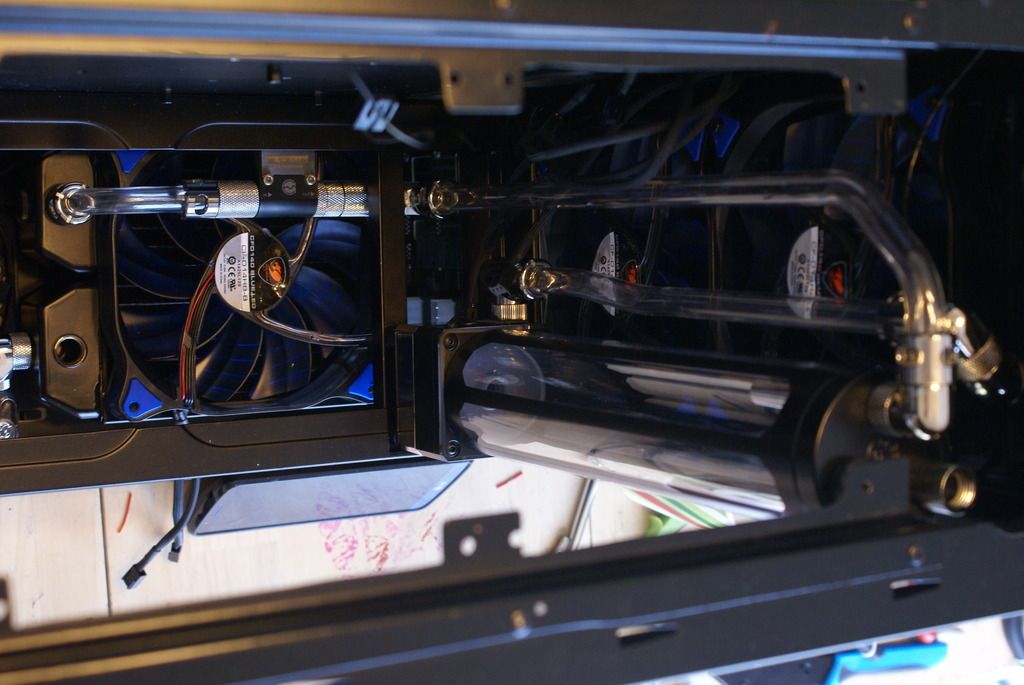

For radiators I chose to go with the Alphacool brand. I chose to go with these beacuse I plan on using lower rpm fans and wanted unitformity with the rads. I will be trying to stuff the lollowing rads into my chosen case:

1- Alphacool Monsta 280mm

1- Alphacool ST30 280mm

1- Alphacool XT45 140mm

1- Alphacool ST30 120mm

For waterblocks I tried to stay uniform and used a combination of EKWB and XSPC blocks:

1- EKWB Supremacy in acrylic/nickel for the 1155 CPU

2- EKWB Acrylic/nickel blocks of the R9 290 rev 2 variety

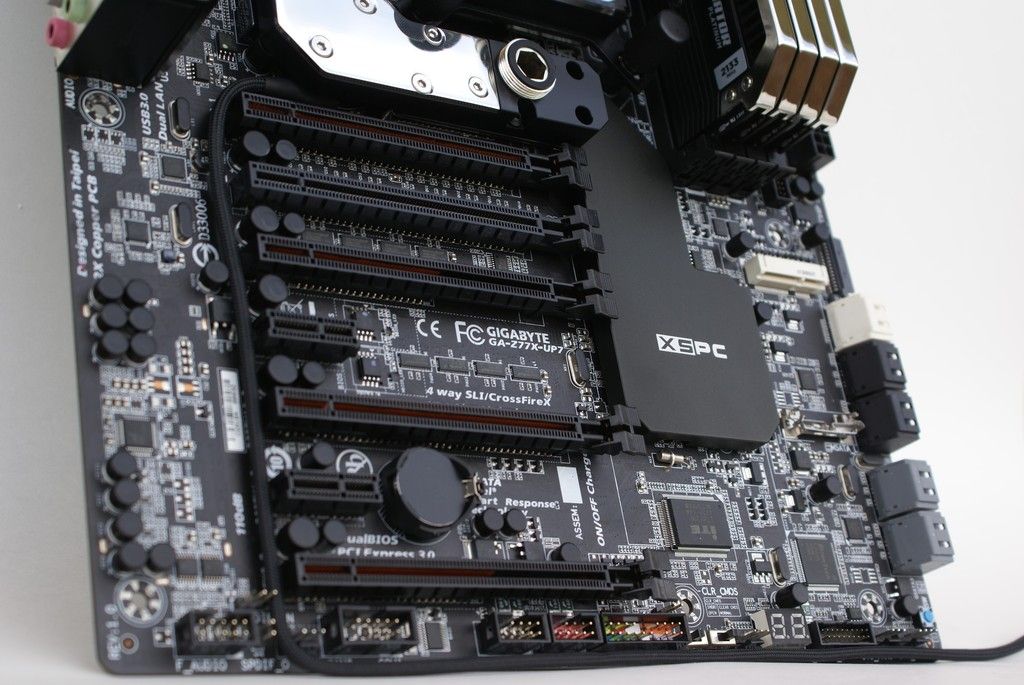

1- XSPC Black Acetal/Copper Block for the z77x-up7

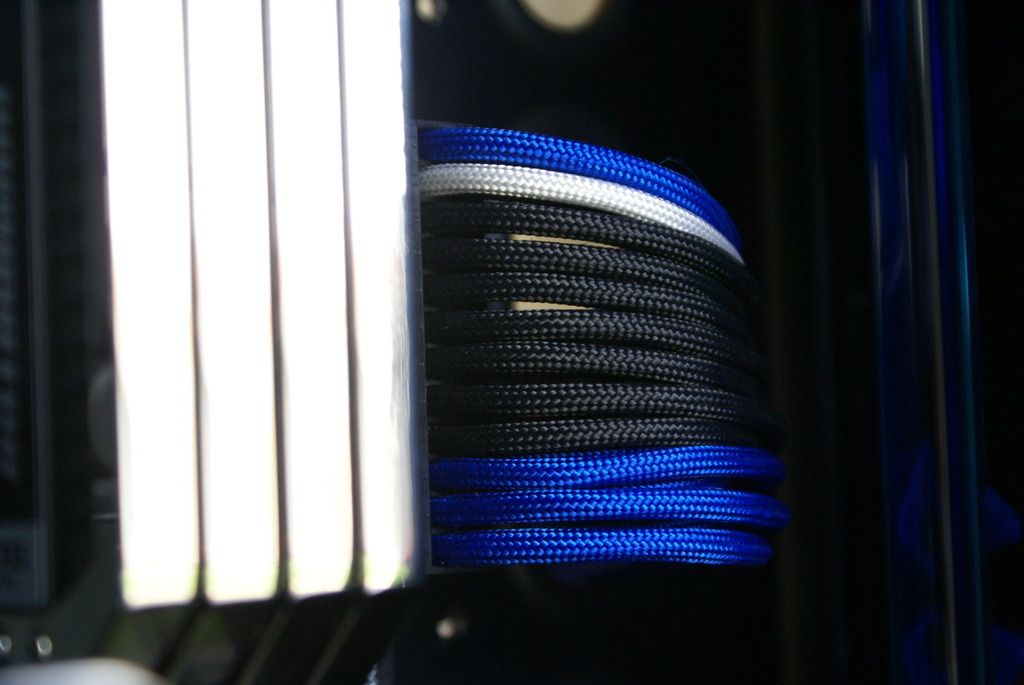

As far as connecting all this equipment together I went with a wide array of different manufacturer fittings. I will be using 1/2" OD acrylic tubing with this particular build and some of the fittings will be as follows:

-Bitspower rotaries

-EKWB rotaries

-Monsoon rotaries

-Monsoon 1/2"OD fittings

-Bitspower Drain valve

-Plugs from both EK and Bitspower

-Extensions from Bitspower and Koolance

Pushing the air through the rads will be Cougar Blue LED 140mm/120mm fans. There will also be a Prolimatech 140mm slim and a 120mm slim fan for odd placement duties.

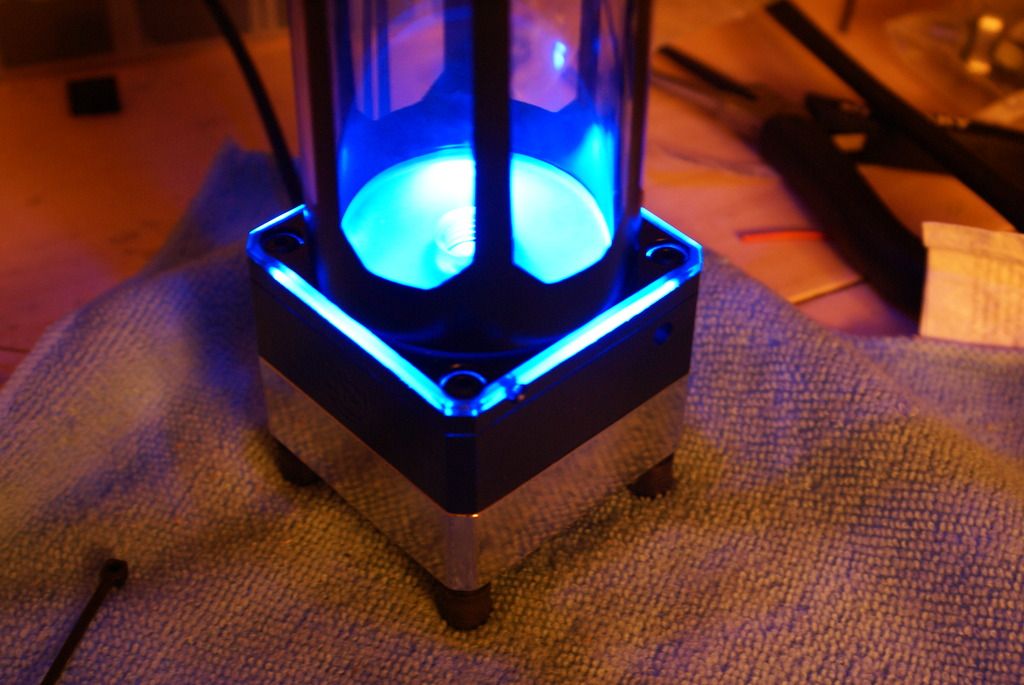

Pushing the fluid will be a Swiftech mpc35x pwm pump with an EK heatsink housing and Bitspower acrylic pump top with add on reservoir. So here is the obligatory too much stuff stacked on top of each other pic;

Here is a picture of the case I will be using:

Now I know that it's not the newest case around or full of watercooling options but ever since I first saw this case, I simply loved the looks of it. To me it reminded me of high end home Stereo equipment and just looks classy to boot. It might not look like much now, but by the time I'm trough it will have all the watercooling options I need plus I think it will look a little better than what it came stock.

Here are some pictures of the hardware I'll be working with. First up is the EK clean acrylic/nickel Supremacy CPU block. (non EVO as I've been collecting parts for a long time, lol)

Next up is one of the EK R9 290 Blocks with backplate. There are 2 pairs of these but one is currently being used in my rig.

Next up is the motherboard with xspc block and some monsoon fittings, Unfortunately the orange will go in a future update, but this is one sexy board.

Here we have a couple of different parts put together. We start off with a Swiftech MCP35x pump, add an EK nickel DDC heatsink, and a Bitspower acrylic top. Then we go for the Bitspower 250 reservoir top upgrade kit and on top of that an upgrade 3 hole top for the res. Bitspower..... the best at nickel and dimin'.

Like I mentioned before I'll be using of different manufacturer fittings but damn these Monsoon ones are rather sexy!

It's not the newest hardware being that when I started Haswell had just come out and unfortunately (or fortunately depending how you look at it) simple life things have lengthened this project.

This should be a fairly quick log as all the work is almost done and I'm at the point where all that's needed is some slight detail work and final pictures. Which I hope to complete in a week or so. Not to mention last time I posted a build here it was only rig pictures instead of a log and I'd like to tell the whole story this time.

This is also the first time I have watercooled a PC and on top of that I decided to jump straight to acrylic tubing. Up until acrylic started becoming mainstream I was seriously turned off of watercooling simply because of aesthetics. When I saw builds using copper (BNEG) and then acrylic I knew a hardline system was something I would definitely be down for. lol

I'm going to start off with system specs/details and pictures. PLease forgive the first couple of pictures as they will get better.

Case...........................................Zalman GS1000

Motherboard...............................Gigabyte GA-Z77X-UP7

CPU............................................Intel I7-3770k

RAM............................................Corsair Dominator Platinum 2133mhz 16GB (4x4gb)

SSD's..........................................OCZ Vertex 4 128GB x2 in RAID 0 (OS+few games)

HDD............................................2TB Seagate 7200rpm (storage)

Power Supply..............................Cooler Master V1000 modular 1000watt

Graphics......................................Saphire R9 290 x2 (reference)

Sound..........................................Creative Sound Blaster Z

Now for the watercooling side of things I have chosen the componets that looks wise fit the look I was looking for. I am not really a brand loyalist and simply use what looks best to me. :thumb:

For radiators I chose to go with the Alphacool brand. I chose to go with these beacuse I plan on using lower rpm fans and wanted unitformity with the rads. I will be trying to stuff the lollowing rads into my chosen case:

1- Alphacool Monsta 280mm

1- Alphacool ST30 280mm

1- Alphacool XT45 140mm

1- Alphacool ST30 120mm

For waterblocks I tried to stay uniform and used a combination of EKWB and XSPC blocks:

1- EKWB Supremacy in acrylic/nickel for the 1155 CPU

2- EKWB Acrylic/nickel blocks of the R9 290 rev 2 variety

1- XSPC Black Acetal/Copper Block for the z77x-up7

As far as connecting all this equipment together I went with a wide array of different manufacturer fittings. I will be using 1/2" OD acrylic tubing with this particular build and some of the fittings will be as follows:

-Bitspower rotaries

-EKWB rotaries

-Monsoon rotaries

-Monsoon 1/2"OD fittings

-Bitspower Drain valve

-Plugs from both EK and Bitspower

-Extensions from Bitspower and Koolance

Pushing the air through the rads will be Cougar Blue LED 140mm/120mm fans. There will also be a Prolimatech 140mm slim and a 120mm slim fan for odd placement duties.

Pushing the fluid will be a Swiftech mpc35x pwm pump with an EK heatsink housing and Bitspower acrylic pump top with add on reservoir. So here is the obligatory too much stuff stacked on top of each other pic;

Here is a picture of the case I will be using:

Now I know that it's not the newest case around or full of watercooling options but ever since I first saw this case, I simply loved the looks of it. To me it reminded me of high end home Stereo equipment and just looks classy to boot. It might not look like much now, but by the time I'm trough it will have all the watercooling options I need plus I think it will look a little better than what it came stock.

Here are some pictures of the hardware I'll be working with. First up is the EK clean acrylic/nickel Supremacy CPU block. (non EVO as I've been collecting parts for a long time, lol)

Next up is one of the EK R9 290 Blocks with backplate. There are 2 pairs of these but one is currently being used in my rig.

Next up is the motherboard with xspc block and some monsoon fittings, Unfortunately the orange will go in a future update, but this is one sexy board.

Here we have a couple of different parts put together. We start off with a Swiftech MCP35x pump, add an EK nickel DDC heatsink, and a Bitspower acrylic top. Then we go for the Bitspower 250 reservoir top upgrade kit and on top of that an upgrade 3 hole top for the res. Bitspower..... the best at nickel and dimin'.

Like I mentioned before I'll be using of different manufacturer fittings but damn these Monsoon ones are rather sexy!

Last edited: